Spring-assisted paintball loader

a technology of springs and paintballs, applied in the field of ammunition feeding mechanisms, can solve the problems of dry firing of the gun, disruption of the paintball queue, etc., and achieve the effect of avoiding dry firing and steady flow of projectiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

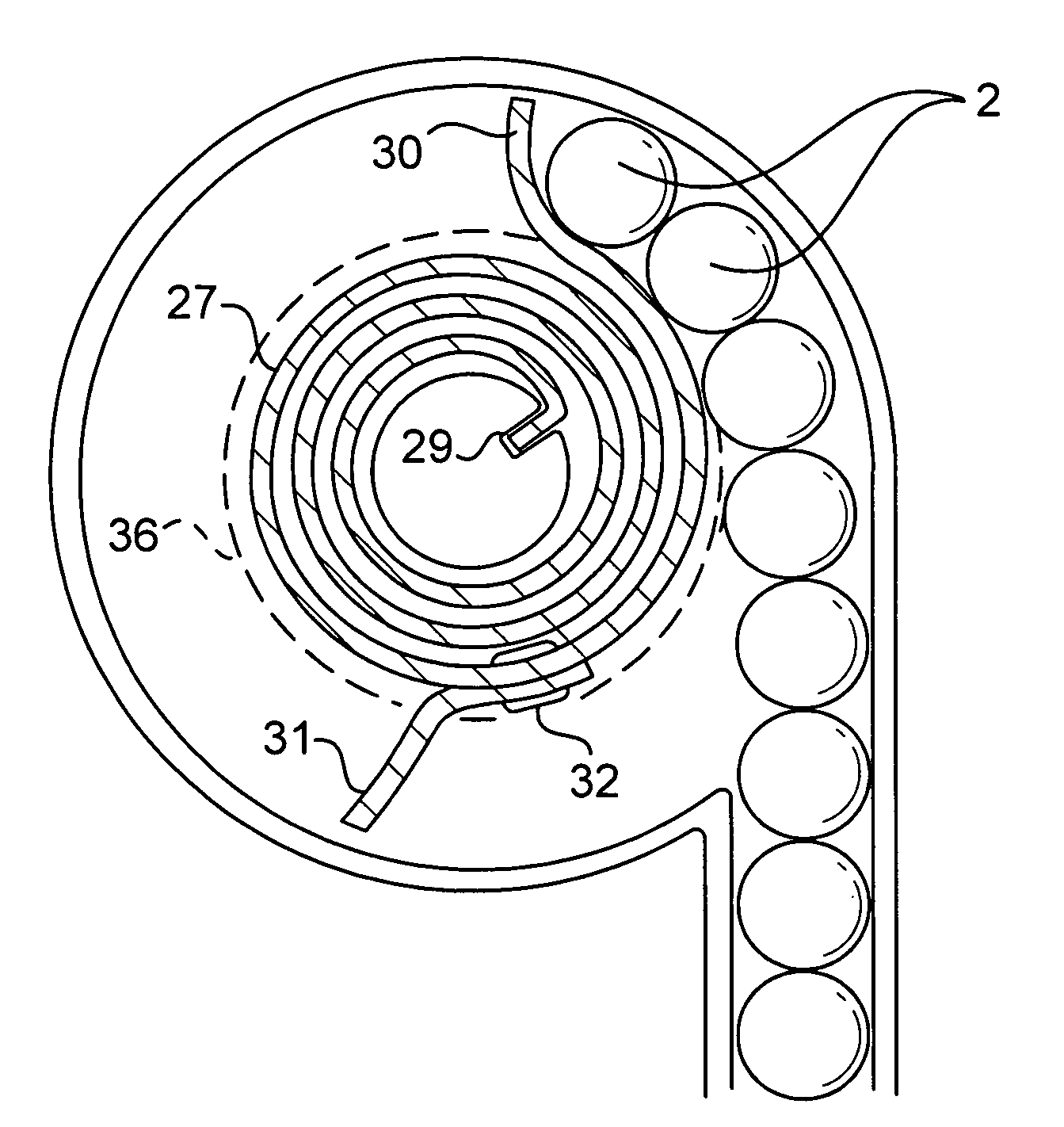

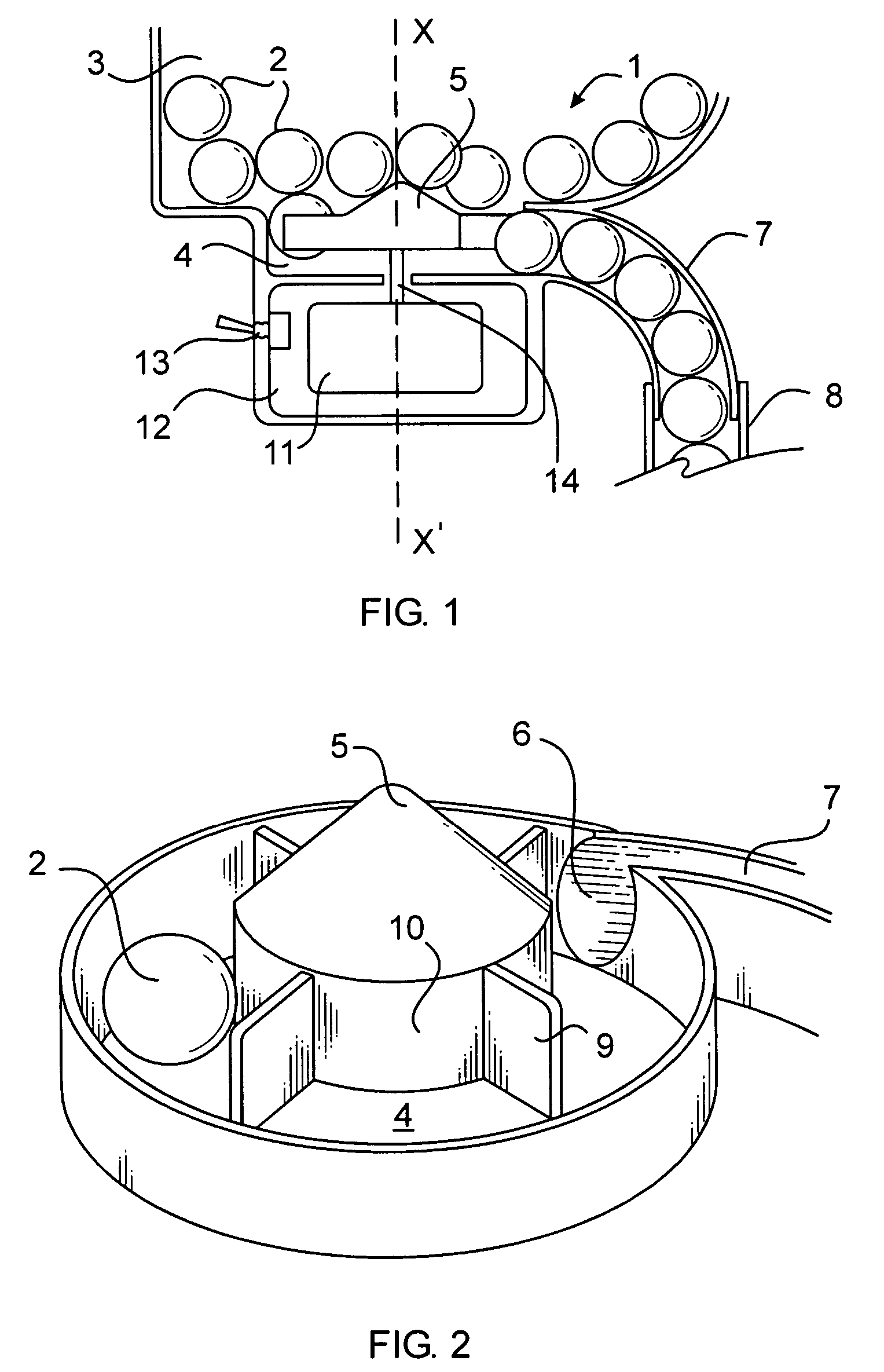

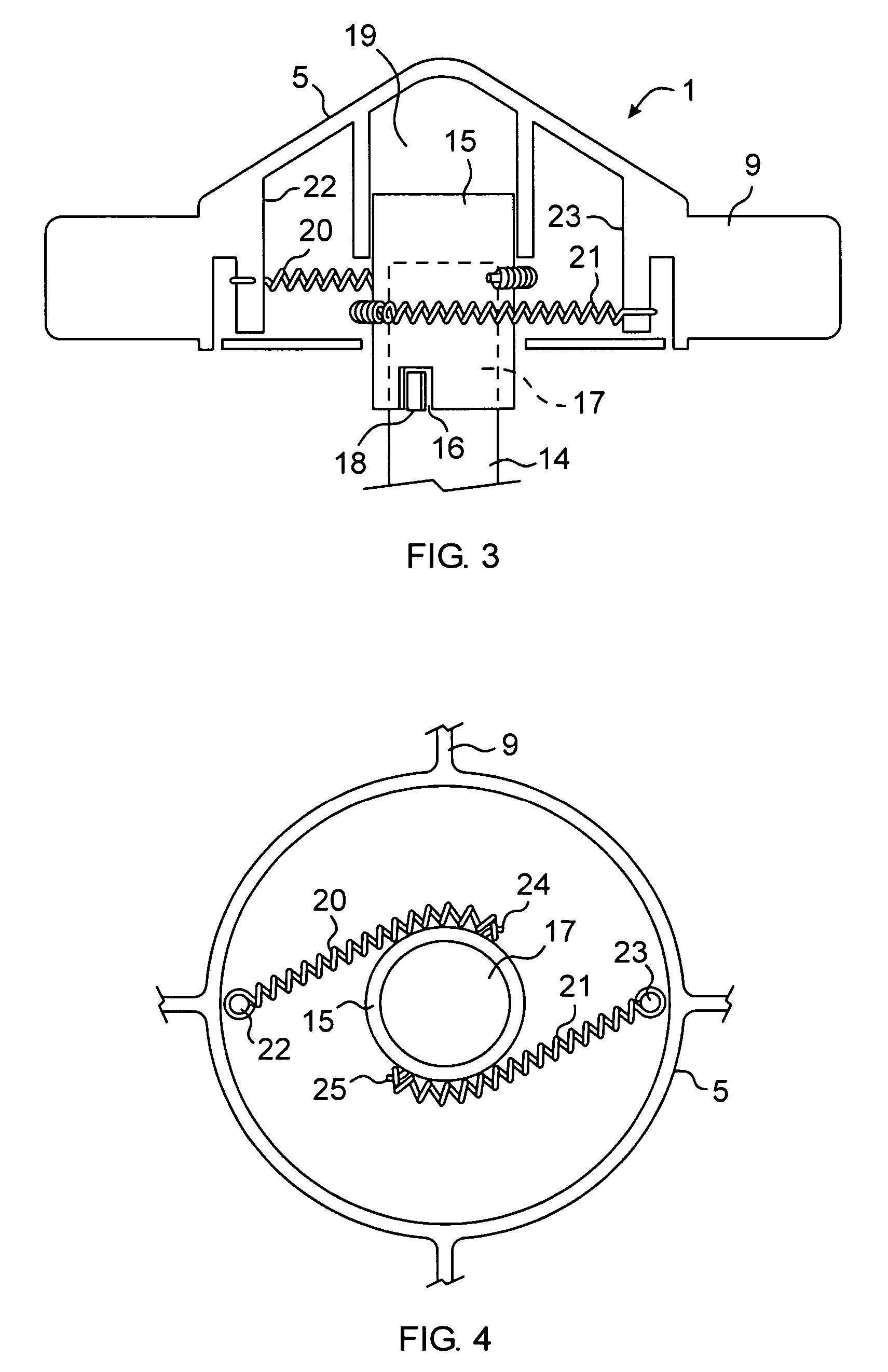

[0013]Referring now to the drawing, there is shown in FIGS. 1-4 a first embodiment 1 of a paintball feeding mechanism according to the invention.

[0014]As paintballs 2 held in the magazine 3 drop into a well 4 in a lower region of the magazine, they are contacted by a spinning body in the form of a spool 5 and directed toward the inlet 6 of a duct 7 leading to the ammunition intake port 8 of a paintball marker or gun. A series of vanes or paddles 9 projecting radially and outwardly from the peripheral, outer wall 10 of the spool act as impelling arms for the paintballs 2. An electrical motor 11 positioned in a housing 12 immediately under the magazine well 4 can be energized and started, then stopped by means of a toggle switch 13. Alternately, as commonly found in certain paintball markers, the start of the motor can be initialized by the trigger mechanism and automatically stopped after a short period of time, or upon release of the trigger. The axle 14 of the motor engages the spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com