Safety electrical outlet and switch system

a switch system and electrical outlet technology, applied in the direction of coupling protective earth/shielding arrangement, coupling device connection, contact member penetration/cutting of insulation/cable strand, etc., can solve the problems of electrical wiring construction, unnecessary installation costs, and installation of wall panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

System Overview

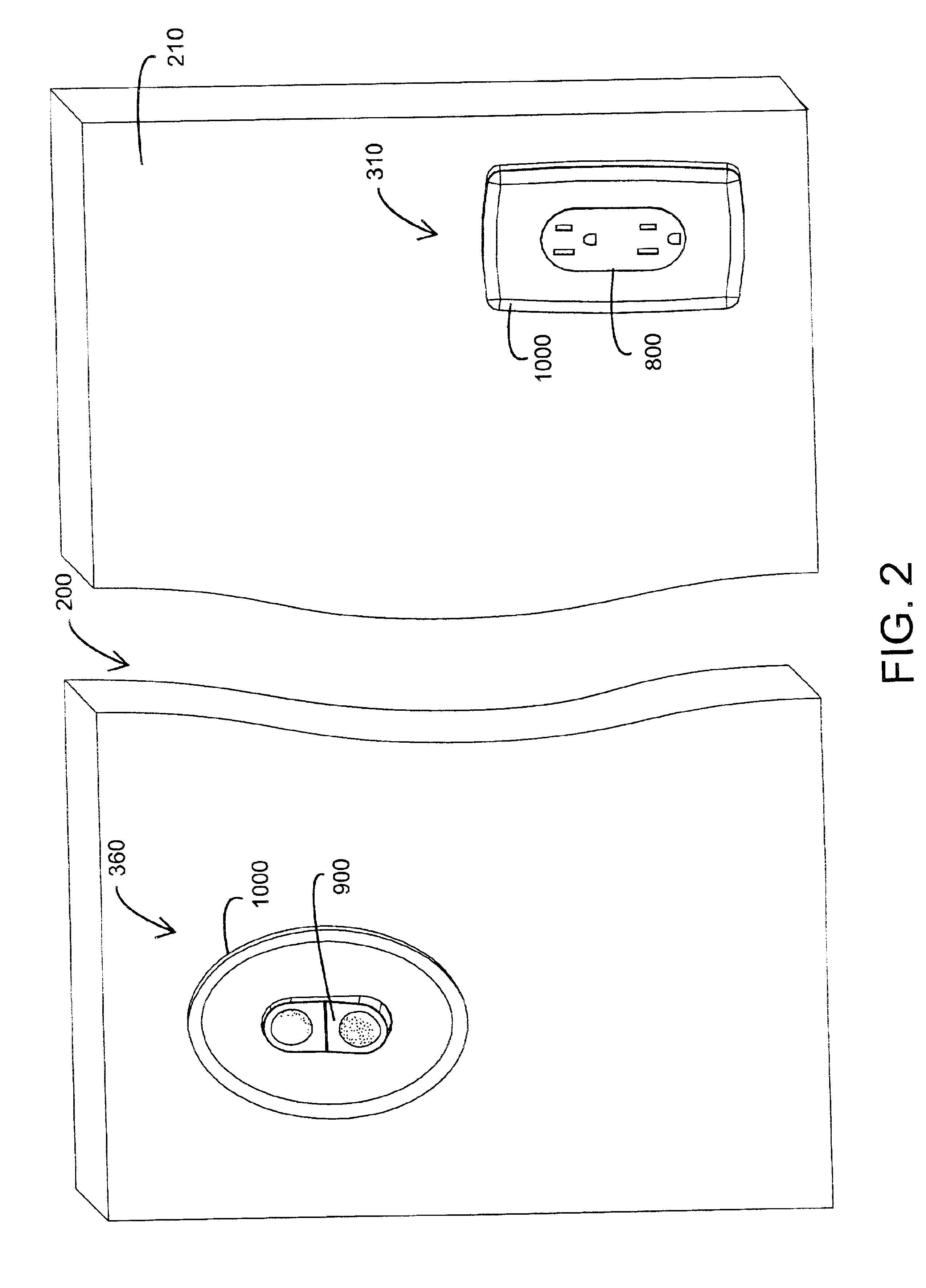

FIG. 2 illustrates one embodiment of an installed safety electrical outlet and switch system 200 according to the present invention. As shown in FIG. 2, the outlet and switch system 200 comprises a outlet assembly 310 and a switch assembly 360. Each of these assemblies 310, 360 provide a user-accessible electrical function. The outlet assembly 310 is mounted in a wall 210 and functions to supply a user with electrical power through a conventional AC plug inserted into an outlet module 800. The switch assembly 360 is also mounted in the wall 210 and functions to allow a user to control electrical power to an outlet, a light or any of various electrical devices (not shown) by actuating a switch module 900. The installed outlet assembly 310 includes a face plate 1000 and an outlet module 800 mounted so that its visible portion is generally flush with the face plate 1000. The installed switch assembly 360 includes a face plate 1000 and a switch module 900 mounted so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com