Compressor housing for turbocharger and method for manufacturing the same

a compressor housing and turbocharger technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of reducing the compression efficiency of supplied air, increasing manufacturing costs, and reducing the workability of assembling, so as to reduce the parts count, improve the workability, and improve the effect of assembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

Embodiment 1

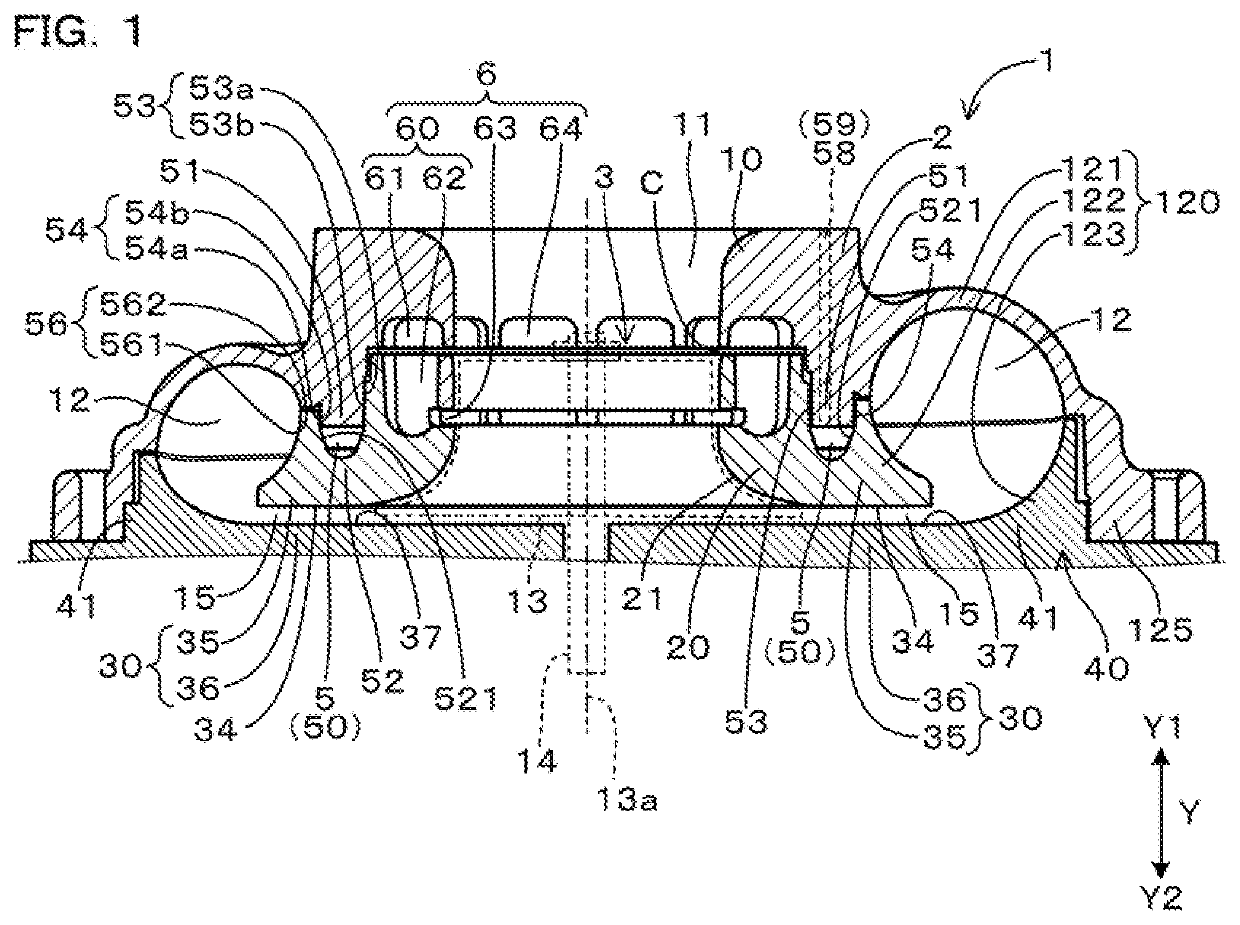

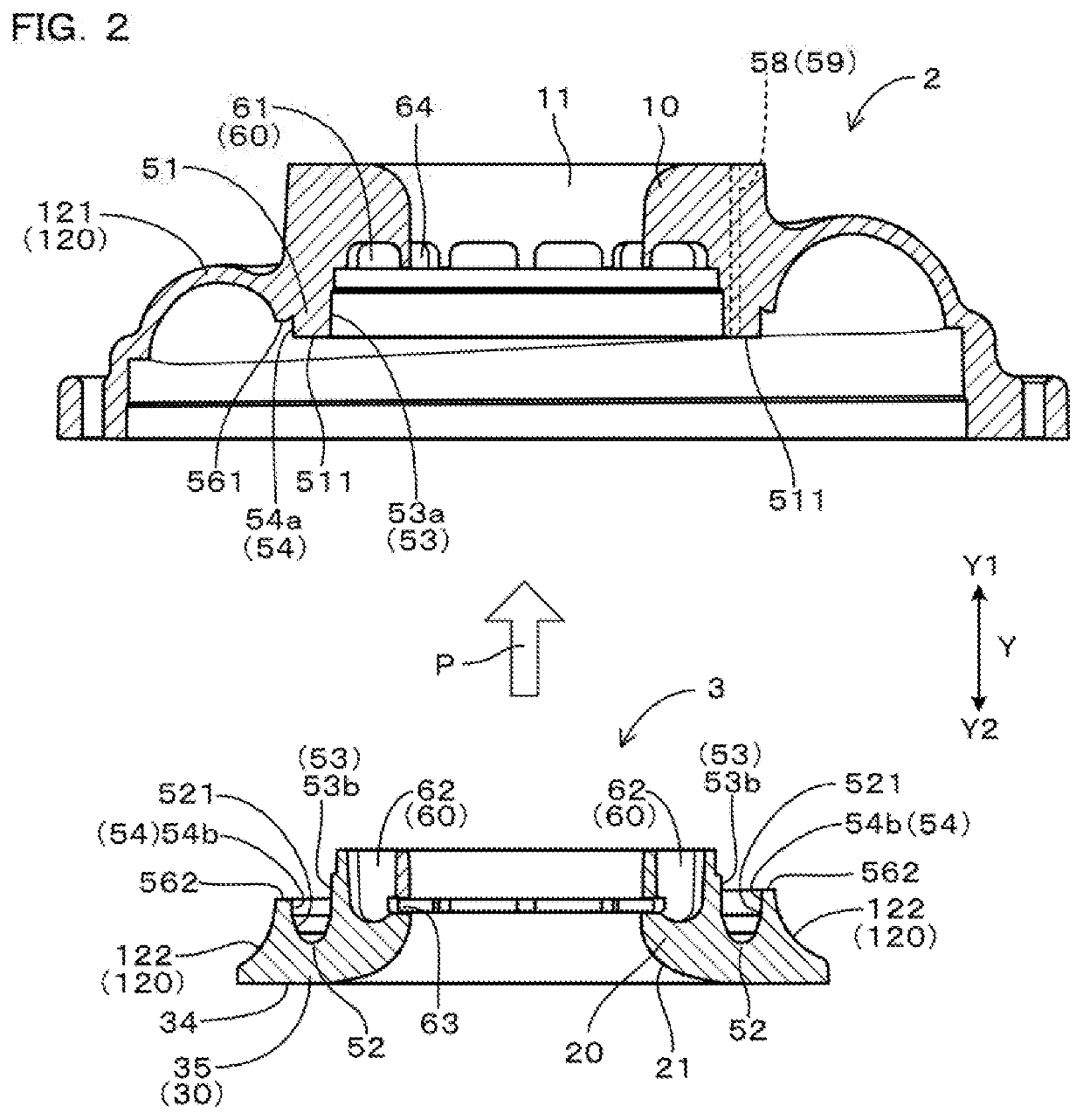

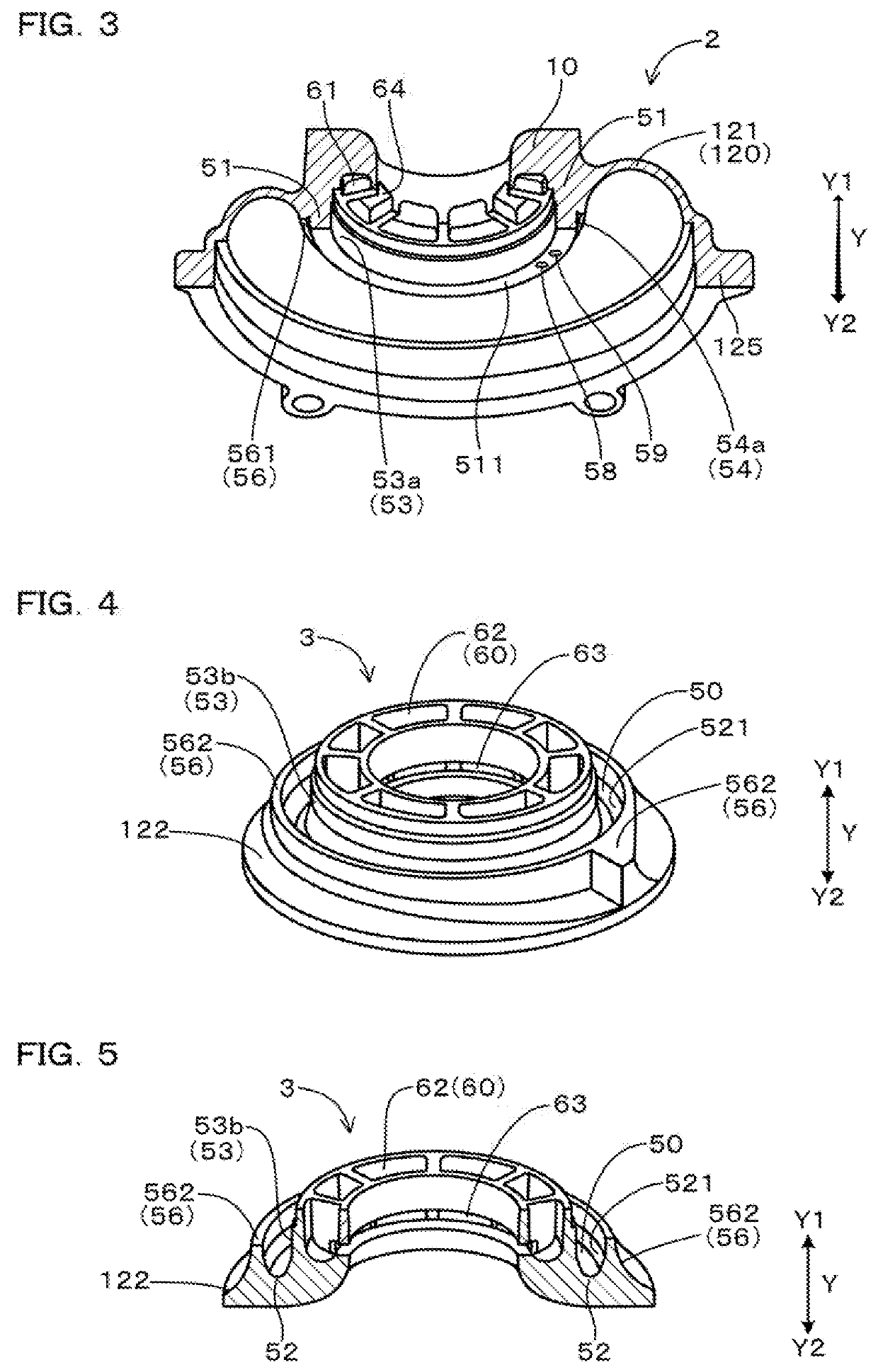

[0048]Hereinafter, embodiments of the aforementioned compressor housing for a turbocharger will be described with reference to FIGS. 1 to 7.

[0049]As shown in FIG. 1, a compressor housing 1 for a turbocharger houses a compressor impeller 13, and is provided with an intake port formation part 10, a shroud part 20, a diffuser part 30, a scroll chamber formation part 120, a refrigerant flow path 5, and a recirculation part 6.

[0050]The intake port formation part 10 forms an intake port 11 configured to suck in air toward the compressor impeller 13.

[0051]The shroud part 20 surrounds the compressor impeller 13 in the circumferential direction and has a shroud surface 21 facing the compressor impeller 13.

[0052]The diffuser part 30 is formed on the outer peripheral side of the compressor impeller 13 in the circumferential direction, and forms a diffuser passage 15 that allows compressed air discharged from the compressor impeller 13 to pass therethrough.

[0053]The scroll chamber f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com