Rock bolt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

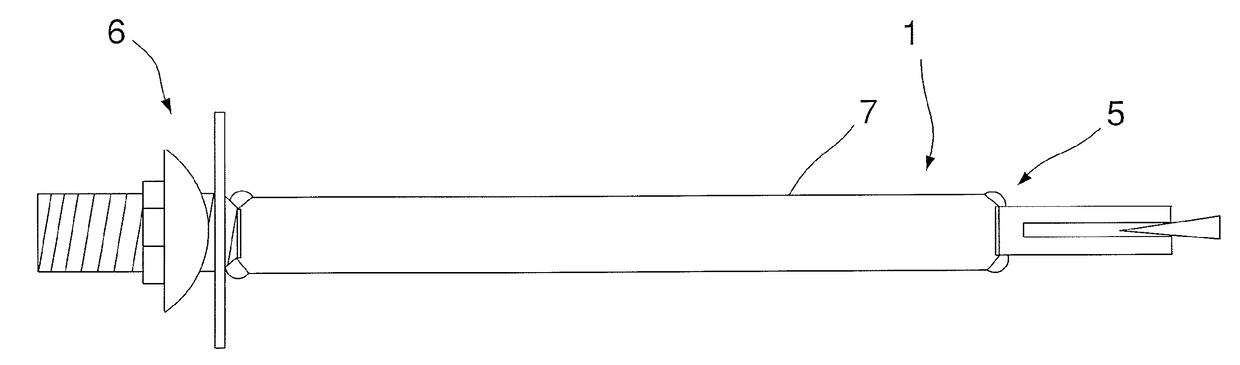

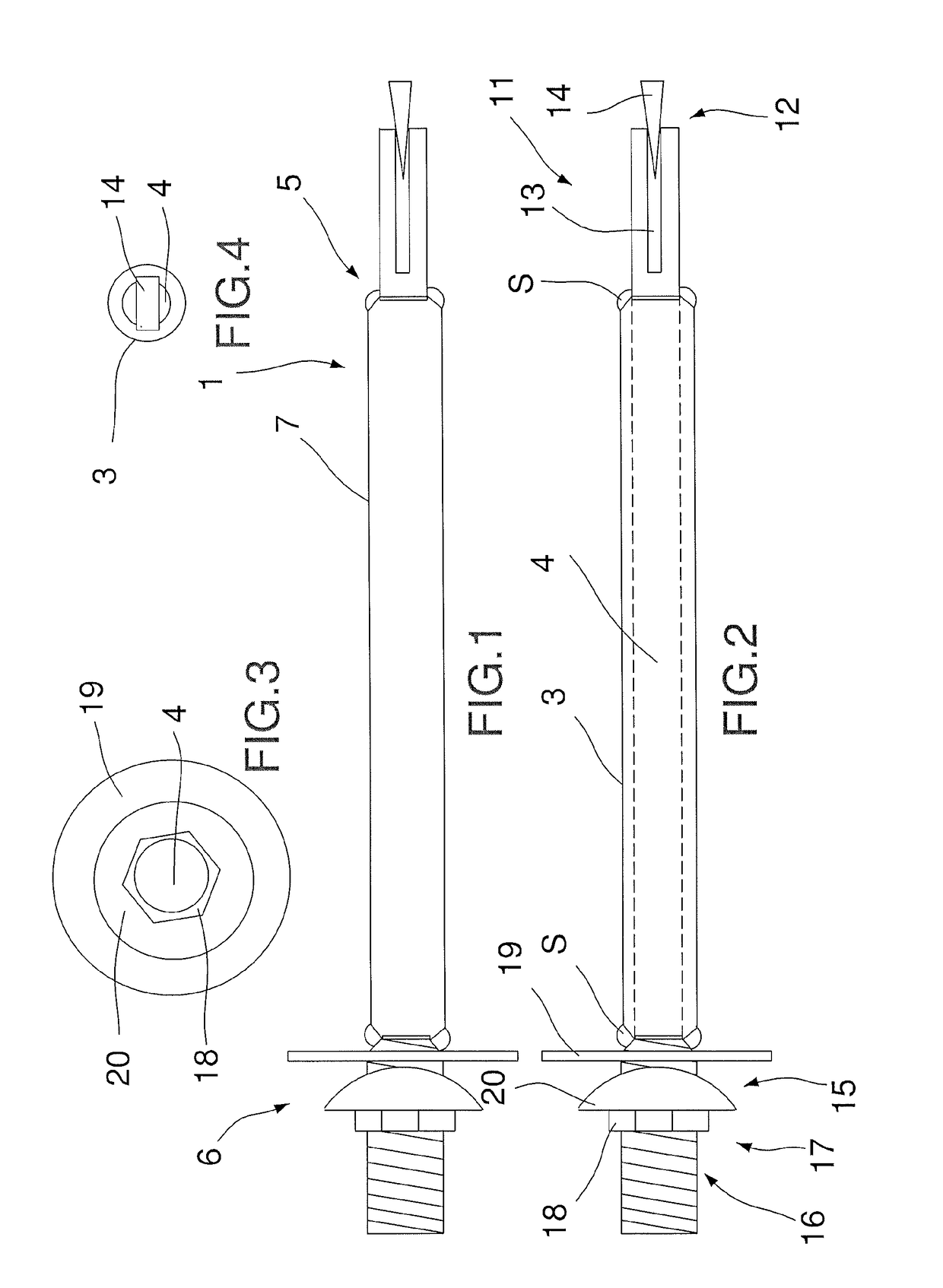

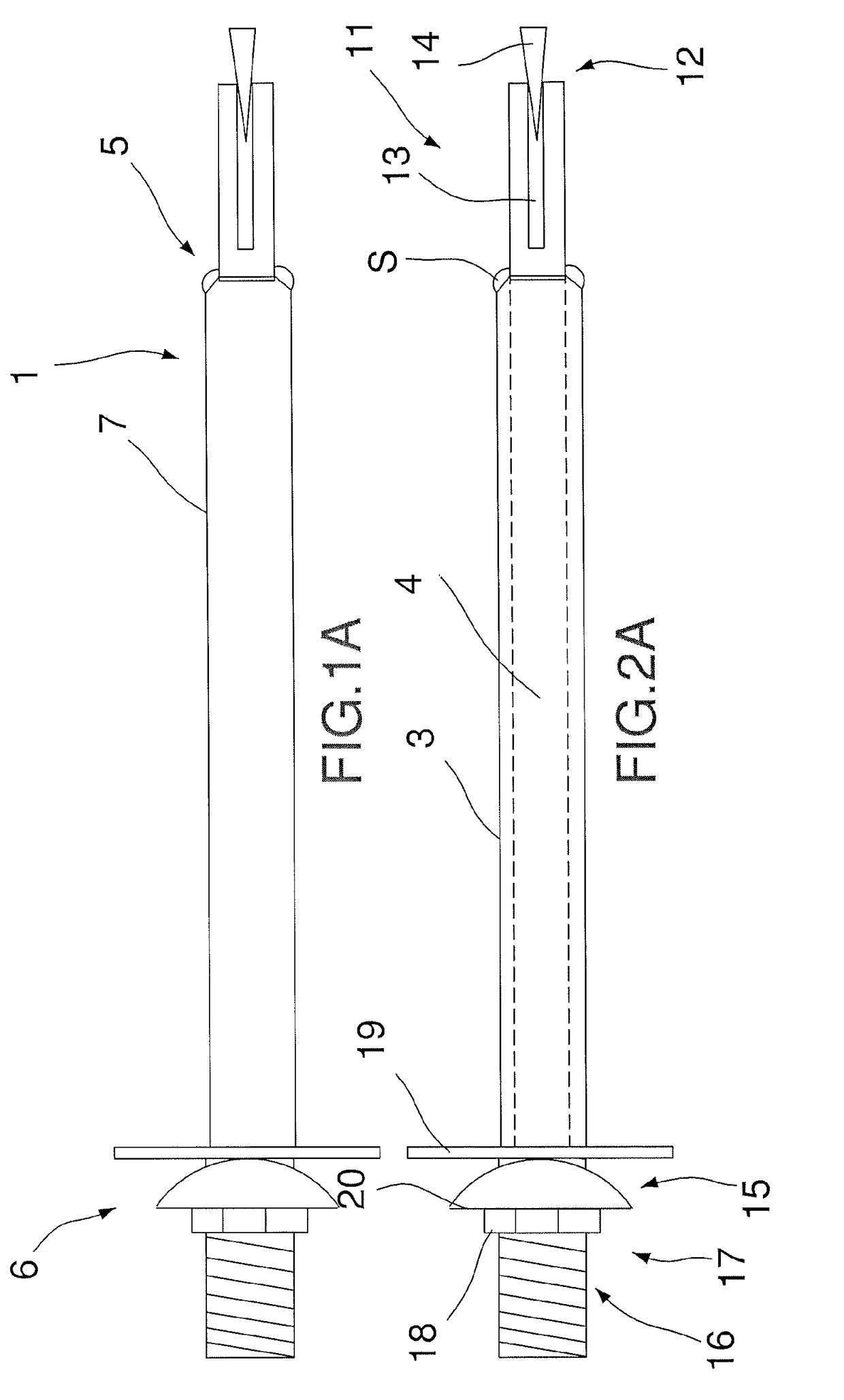

[0026]FIG. 1 shows a rock bolt 1 according to the invention intended to be embedded in a borehole 2 in rock. The rock bolt 1 comprises an extended external tubular part 3 and an internal extended energy-absorbing part 4. In one preferred embodiment, the external part 3 has been given a length that is somewhat less than the length of the energy-absorbing part 4. The external tubular part 3 has a first end 5 and a second end 6, and a magnitude that allows the energy-absorbing part 4 to be surrounded by the external part 3. It is an advantage if the external part 3 has circular cross-section in the form of a circularly symmetrical metal tube, but it should be realised that also other forms and materials are possible. Square, elliptical or rectangular tubes, of metal, plastic or composite material can, for example, be used. Also other forms of the external tubular part 3 can be used.

[0027]The jacket 7 of the external tubular part 3 is, as is shown in FIGS. 6a-6c, arranged with a frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com