Low-collateral damage directed fragmentation munition

a technology of low-collateral damage and fragmentation, applied in the direction of ammunition projectiles, weapons, projectiles, etc., can solve the problems of fracture of steel casing into metal fragments, tight timing tolerances for aimpoint and detonation, and high cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

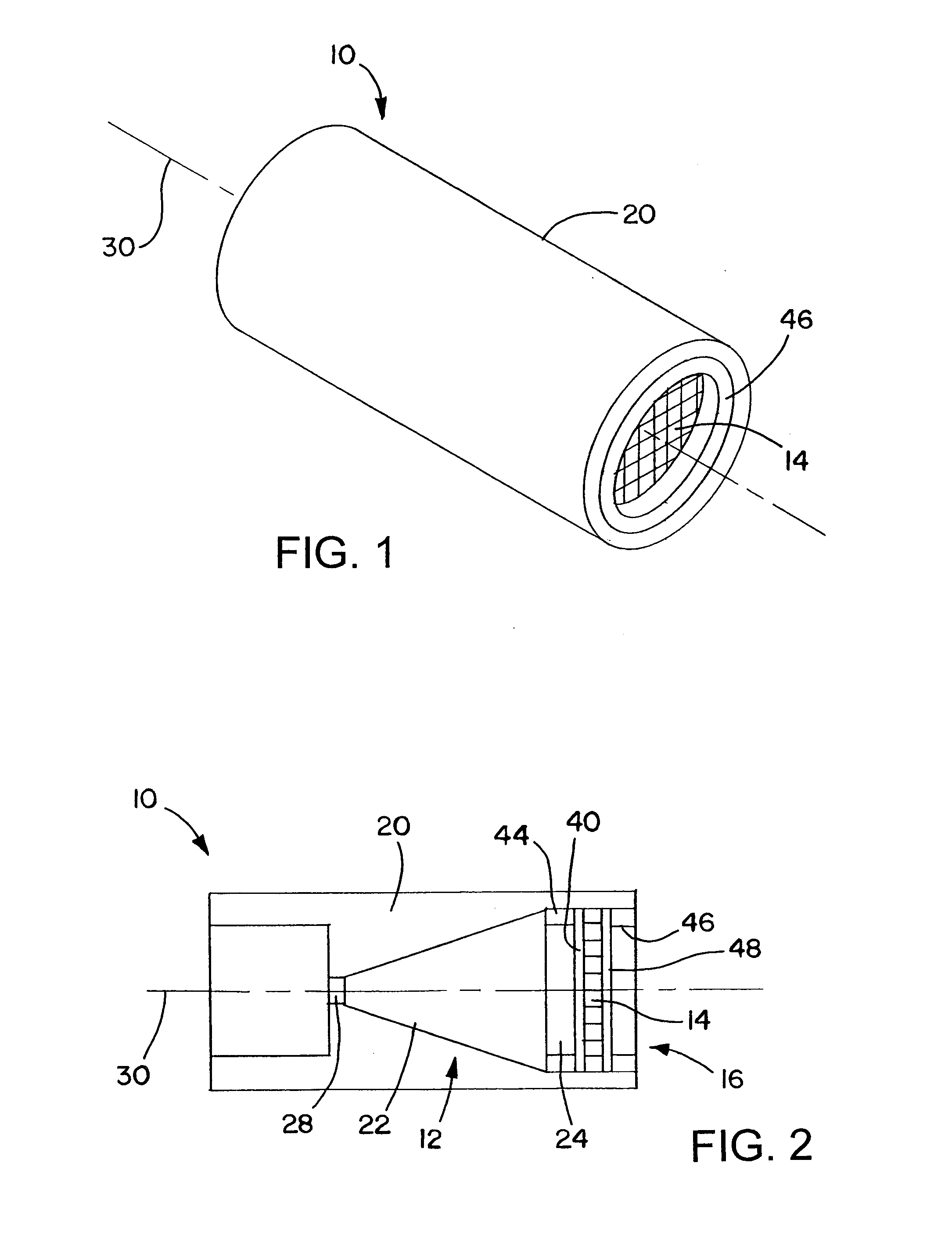

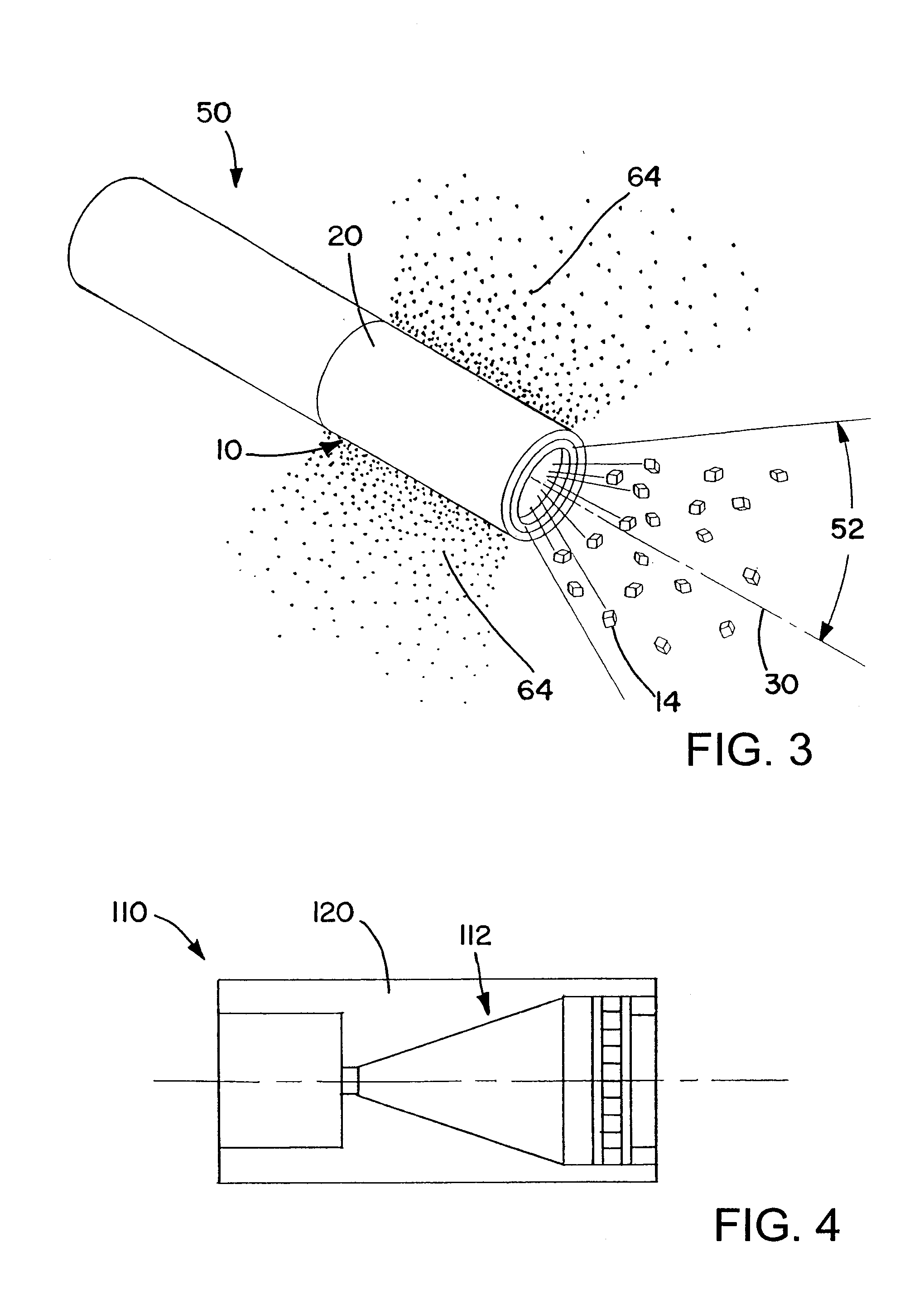

[0014]A directed munition has a non-fragmentation casing, and an explosive within the casing that is configured to propel fragments out an opening of the casing when the explosive is detonated. The casing may be made of plastic or a composite material, or another low density material that does not produce lethal or injurious fragments when the explosive is detonated. The explosive may include an insensitive explosive portion that creates the shape of an explosive front, and a secondary explosive containing a more energetic explosive, which is closer to the fragments than the insensitive explosive portion. There may be more of the insensitive explosive than the relatively energetic explosive, with the insensitive explosive for example constituting a majority of the circumferential surface area of the explosive.

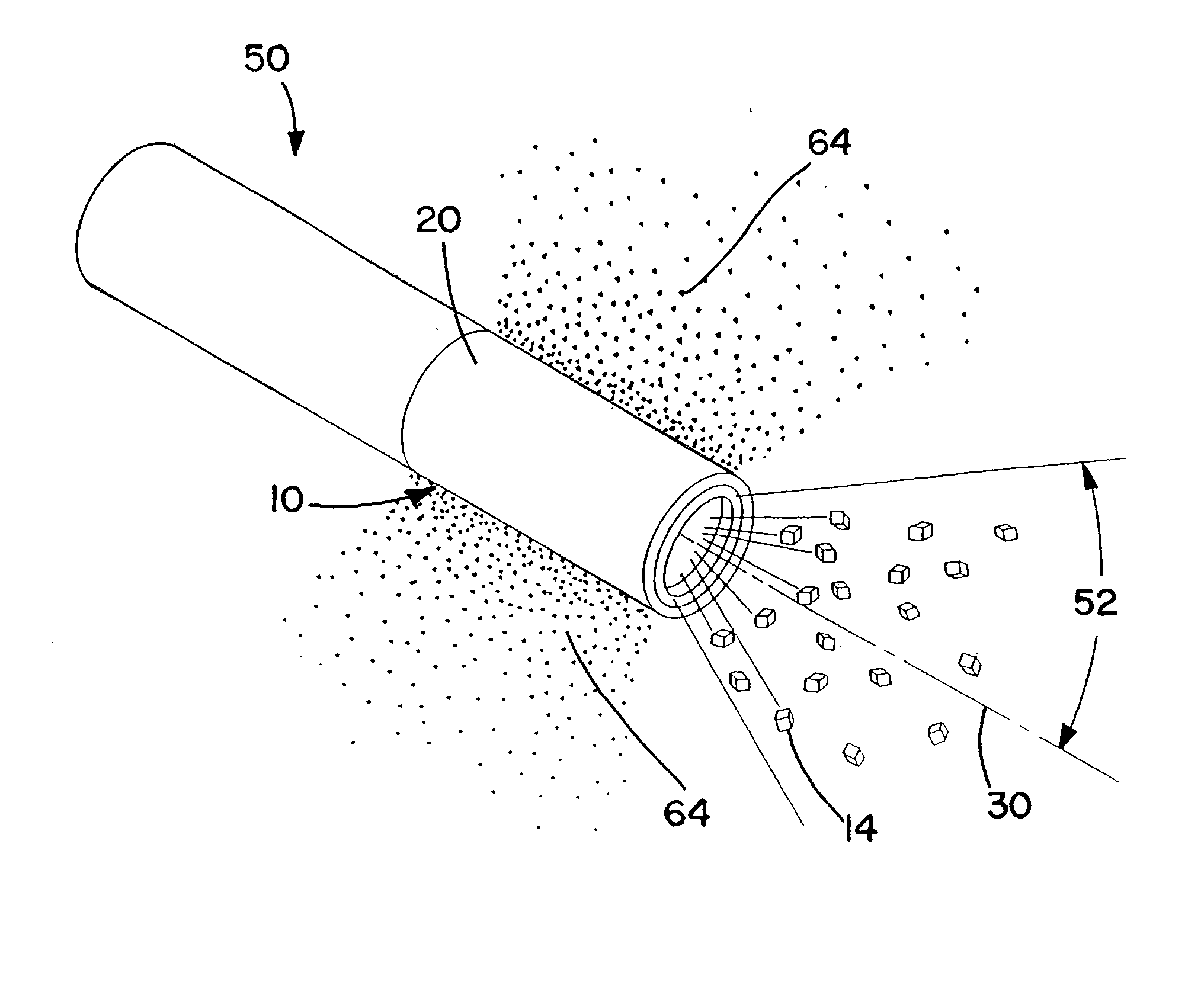

[0015]FIGS. 1 and 2 show a munition 10 that uses an explosive 12 to direct fragments 14 out of an opening 16 in the front of a casing 20 that encloses the explosive 12 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com