A piston pump arrangement for hygienic processing applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

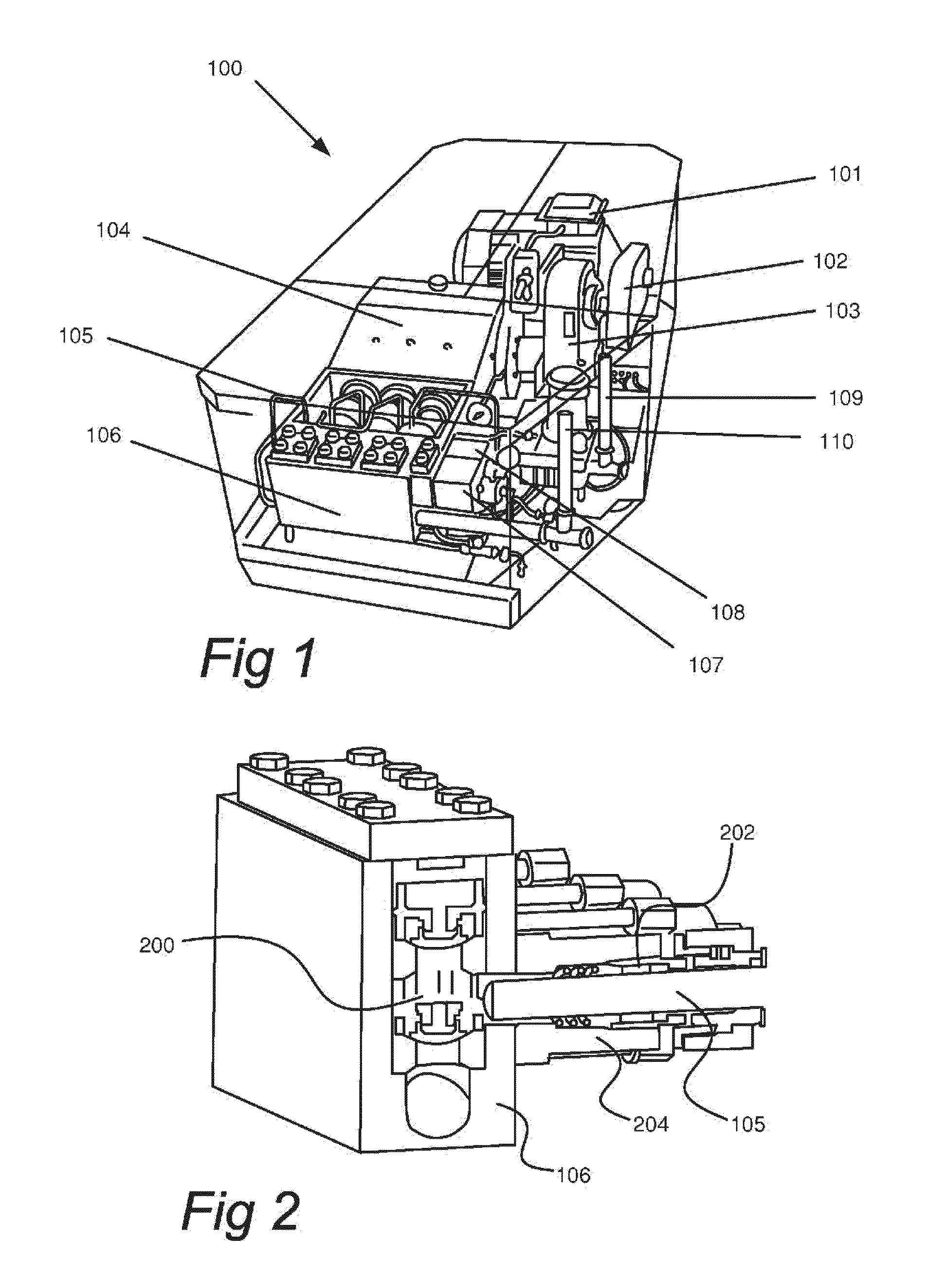

[0041]FIG. 1 generally illustrates a homogenizer 100, more particularly a homogenizer sold under the name Tetra Alex™ by Tetra Pak. Generally, the homogenizer 100 comprises two main parts, a high pressure pump and a homgenising device. The high pressure pump forms a high pressure and the homogenising device provides one or several gaps through which the product is forced with the effect that smaller fat globules are formed. Further effects of homogenization is more appetizing colour, reduced sensitivity to fat oxidation, more full-bodied flavour and better stability of cultured milk products.

[0042]In this example, the high pressure pump is a piston pump driven by a main drive motor 101 connected via a belt transmission 102 and a gearbox 103 to a crankshaft placed in a crankcase 104. By using the crankshaft the rotary motion is converted to a reciprocating motion driving pump pistons 105 back and forth. Today, it is common to have three to five pump pistons.

[0043]The pump pistons 105...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com