Gravity wheel de-stemmer

a gravity wheel and de-stemmer technology, applied in the field of gravity wheel destemmer, can solve the problems of increasing the time-consuming task of de-stemming the pods, affecting the production efficiency of pepper growers, and still accounting for 40-60 percent of the production cost of hand harvesting. , to achieve the effect of reducing energy consumption, simple operation and maintenance, and rapid roi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

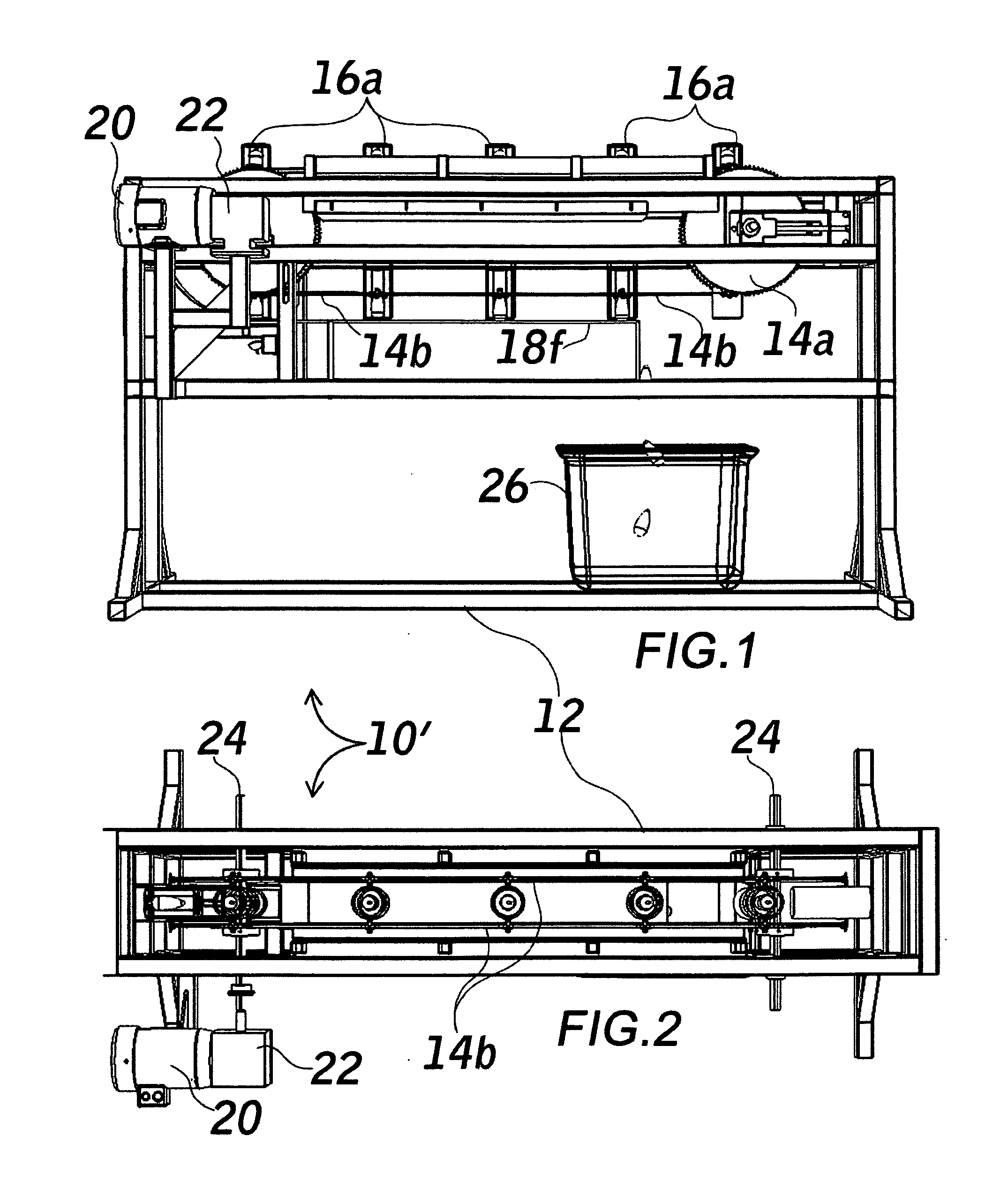

[0015]FIG. 1 is side elevation of a preferred embodiment according the present invention;

[0016]FIG. 2 is a top view of a preferred embodiment according the present invention;

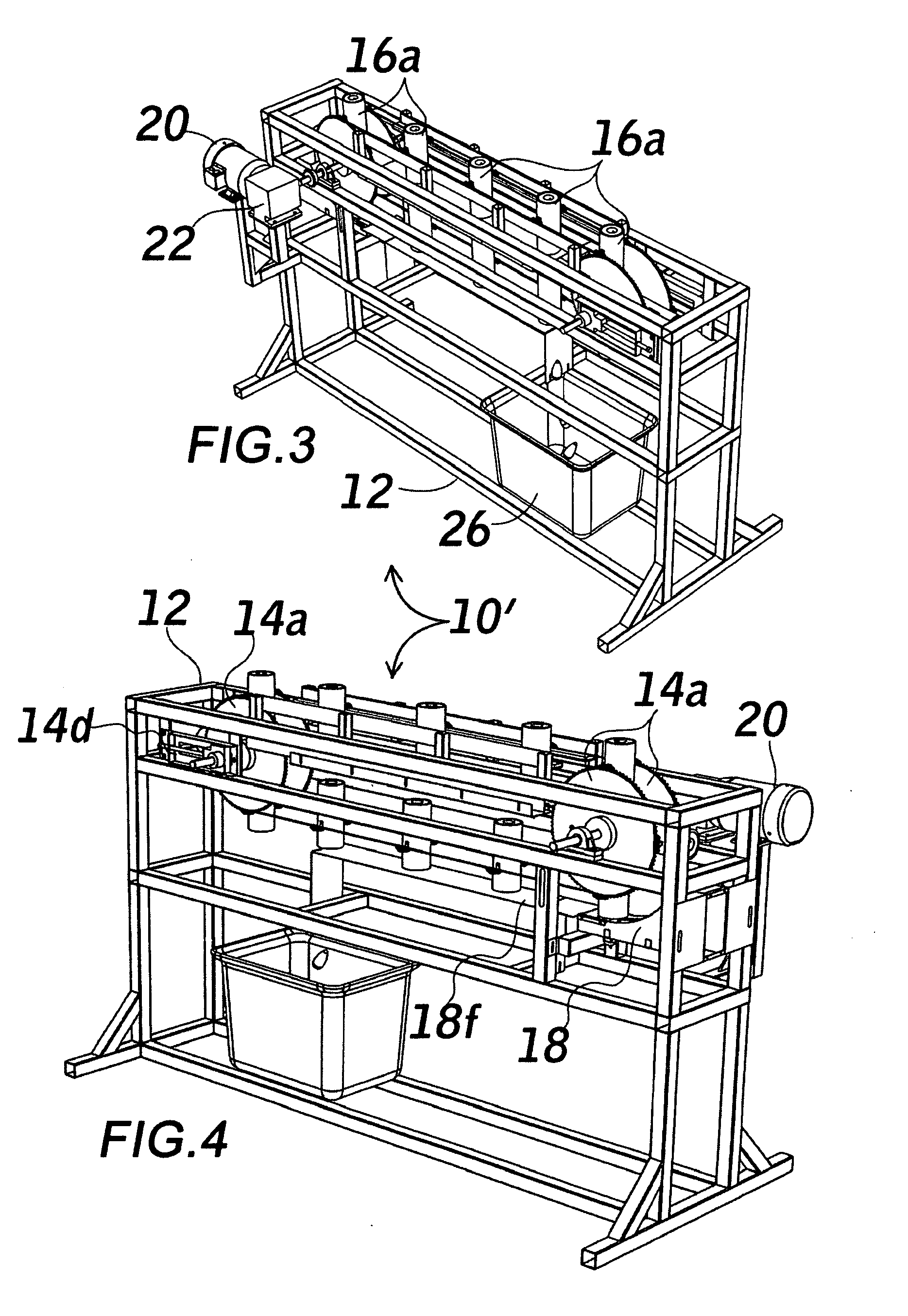

[0017]FIG. 3 is a perspective view of one side of the preferred embodiment;

[0018]FIG. 4 is a perspective view of the obverse of (FIG. 3)

[0019]FIG. 5 is perspective view of the preferred embodiment excluding the frame subassembly;

[0020]FIG. 6 is a detail perspective view of the cutter subassembly 18;

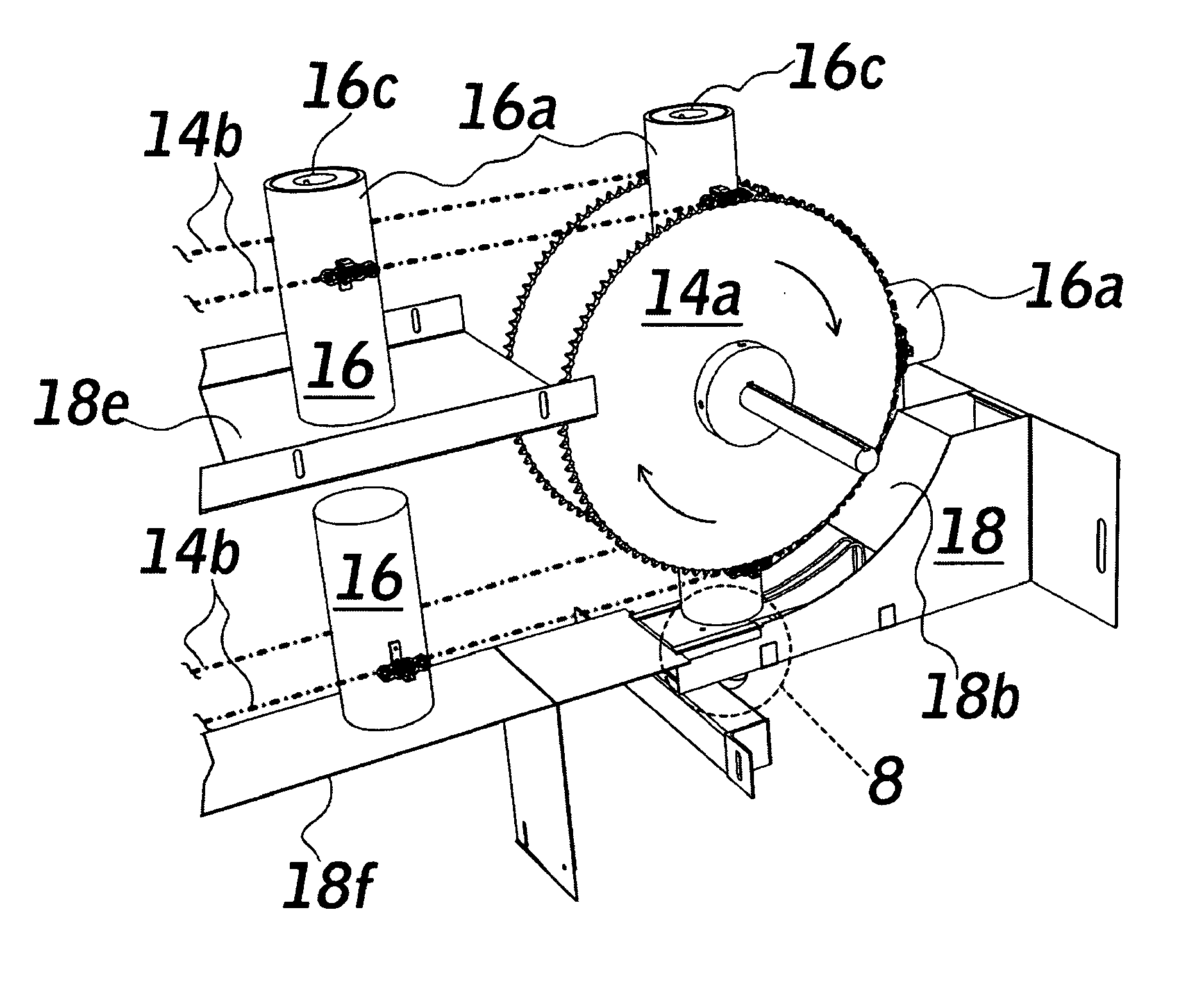

[0021]FIG. 7 is a partial perspective view of one side of the apparatus showing the position of a coaxial sprocket pair relative to the cutter subassembly 18 in accordance with the present invention;

[0022]FIG. 8a is a first detail view of element 8 of (FIG. 7) showing a pepper cap 29 being supported by guide rods 18c;

[0023]FIG. 8b is a second detail view of element 8 of (FIG. 7) showing a pepper after contact with cutter 18d having been de-capped;

[0024]FIG. 9 is a partial perspective view of one embodiment according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com