Method of removing wellbore fluid from well and water removal well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

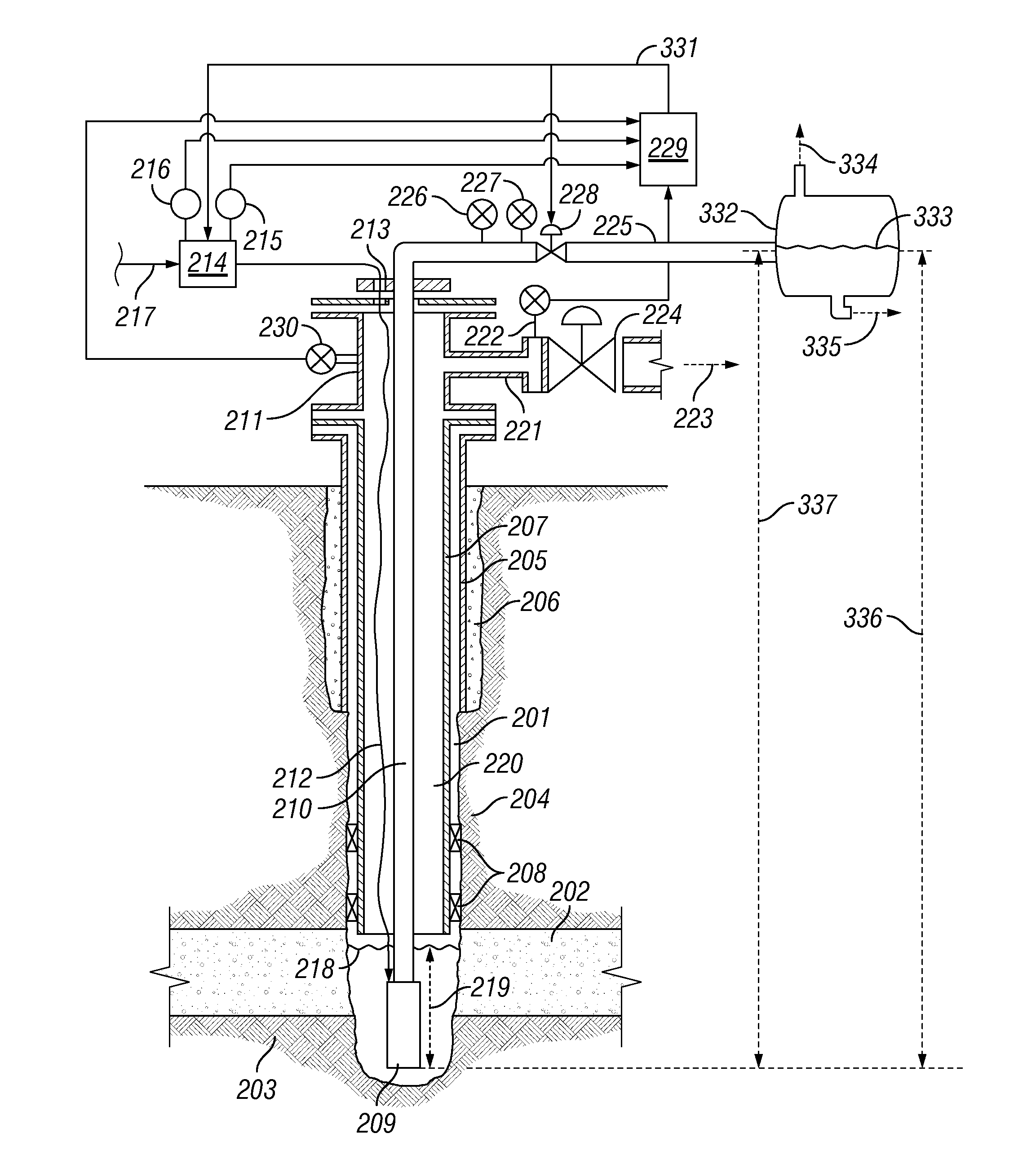

[0012]FIG. 1 is an exemplary pump curve figure. Line 1 shows a function of head in the vertical axis as a function of flow rate on the horizontal axis for a particular speed. Lines 2 through 4 show the same curves for progressively lower speeds. Line 10 shows pump horsepower on the vertical axis as a function of flow rate on the horizontal axis, again for one pump speed. Lines 11 through 13 show the same curves for progressively lower speeds. Line 20 shows system efficiency as a function of flow rate for one pump speed, and lines 21 through 23 show this function for progressively lower pump speeds. Curves like this are available for commercially available pumps from the manufactures or marketers of the pumps.

[0013]The pump curves like those shown in FIG. 1 could be expressed, for example, as polynomials where power and head are given as a function of flow rate and speed, or alternately, the head could be determined as a function of flow rate and power consumption. These functions co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com