Simulated shell-throwing action of toy gun mechanism

a toy gun and mechanism technology, applied in the field of simulated shell-throwing action of toy gun mechanism, can solve the problems of insufficient air storing amount (air pressure), inability to obtain a relatively large cylinder, and difficulty in achieving the effect of simulated shell-throwing action and effect during actual gun shooting, etc., to achieve the effect of improving the fun feeling of toy gun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

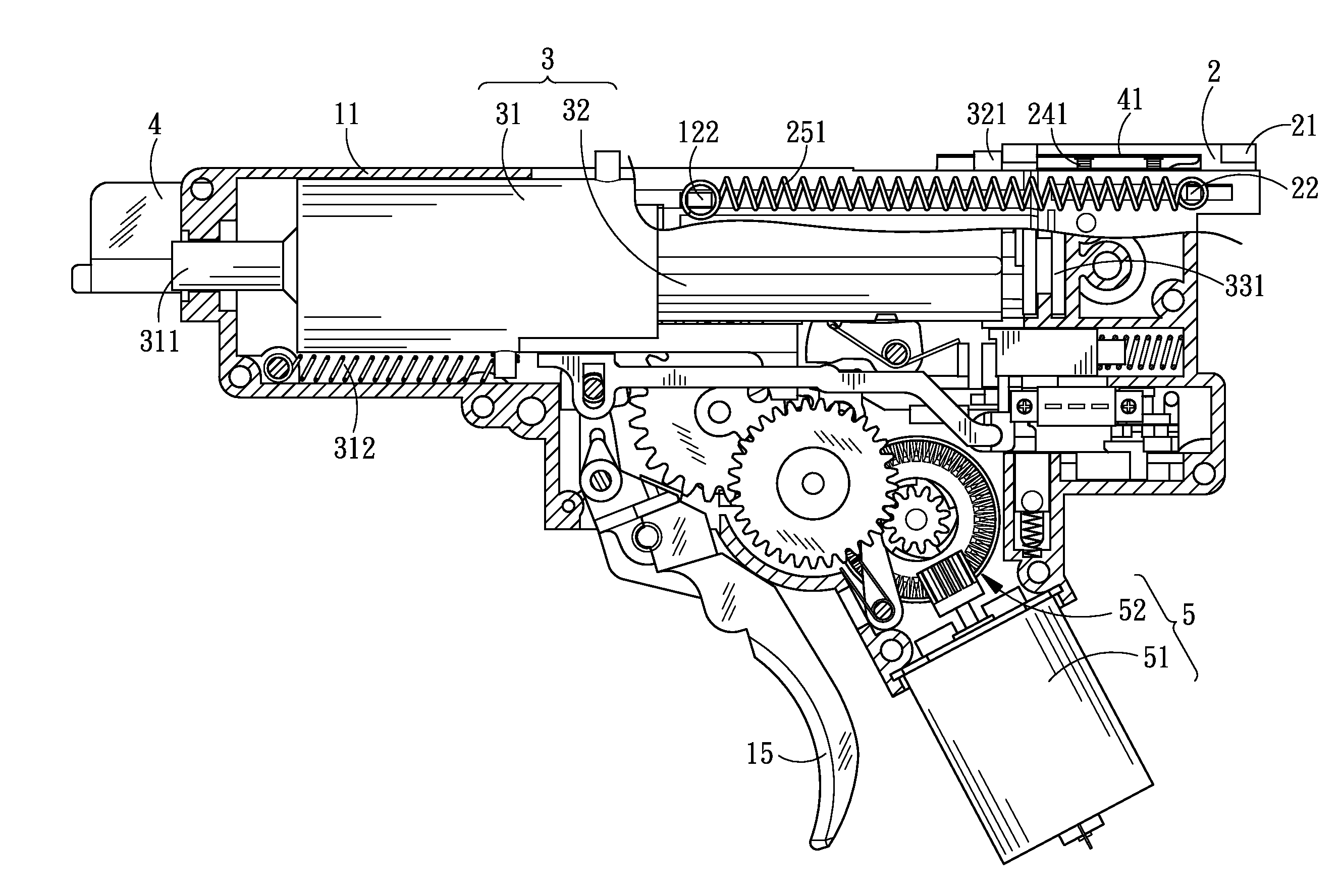

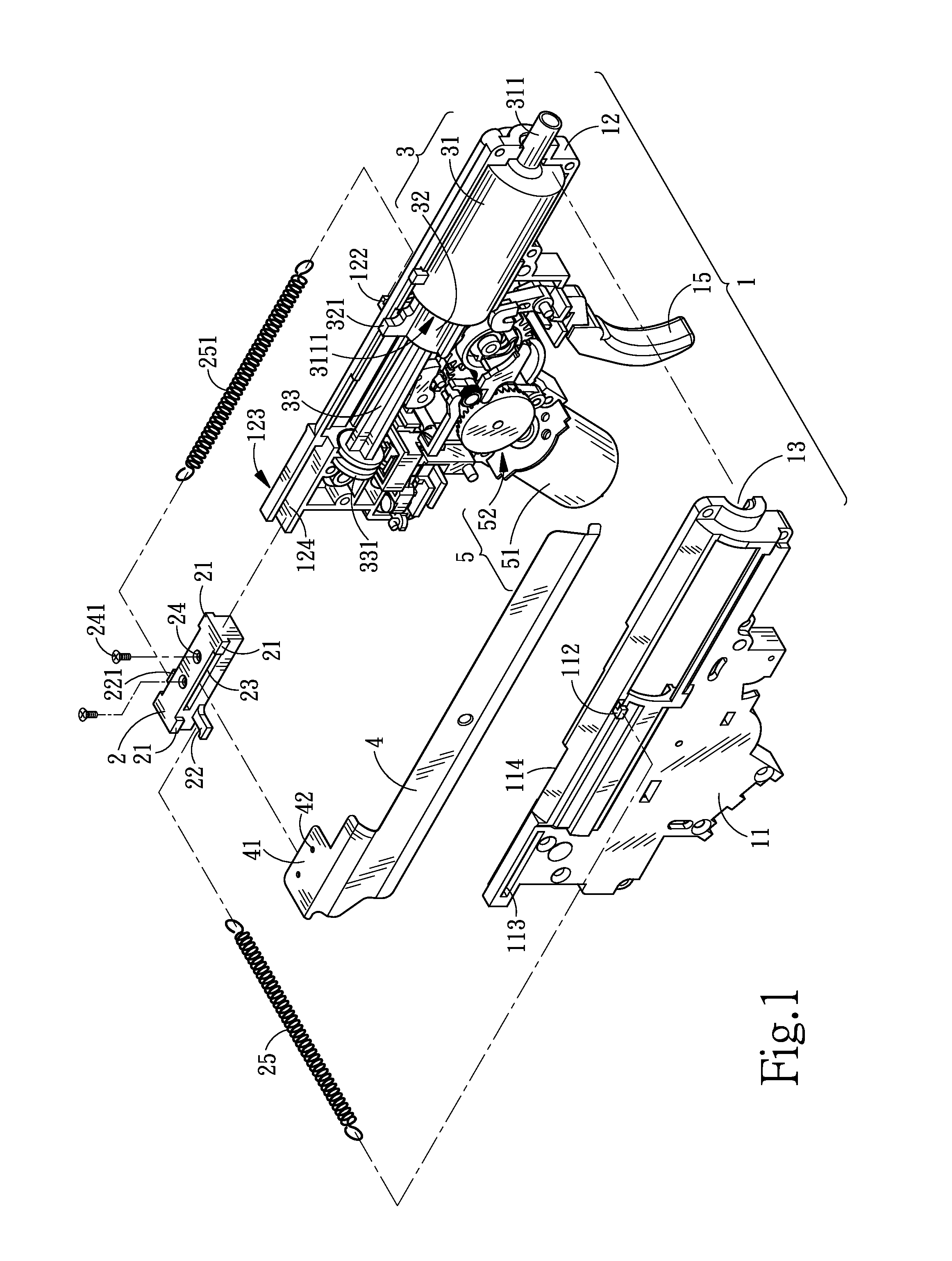

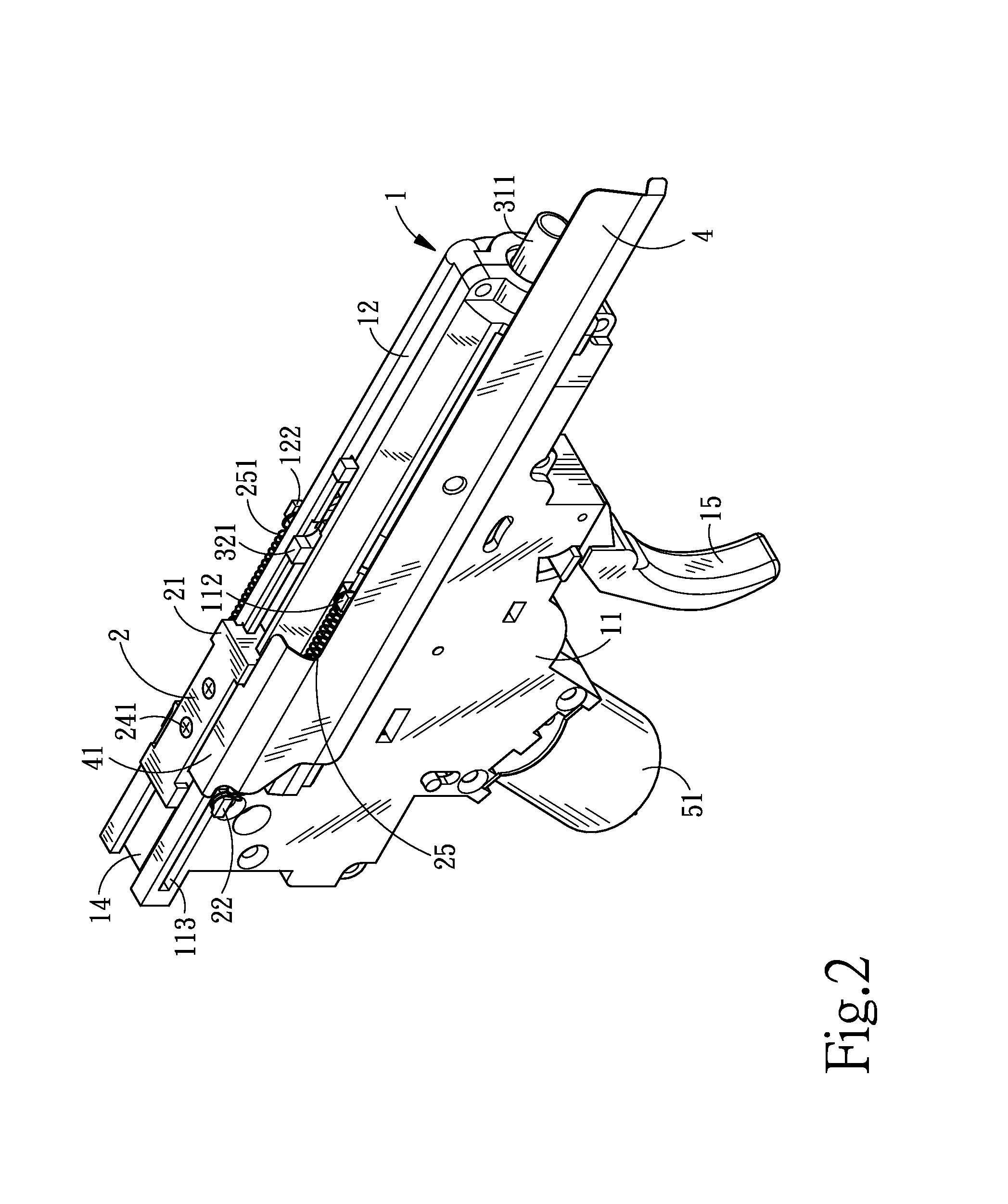

[0025]FIG. 1 is an isometric and exploded view of the related element package of the toy gun mechanism of the invention, FIG. 2 is an isometric view of the outward appearance of the overall assembled structure of the toy gun mechanism of the invention, while FIG. 3 is a front cross-sectional view of the overall assembled structure of the toy gun mechanism of the invention. As shown in FIG. 1, FIG. 2, and FIG. 3, the toy gun mechanism mainly includes an internal gun shell (1), a pull cap (2), a triggering component (3), and a shell throwing decorating plate (4). The internal gun shell (1) is combined by two opposite half gun shells (11), (12) where the two half gun shells (11), (12) have two opposite external hook parts (112), (122) furnished in the mid-section and on the external sides thereof. Side guided-channels (113), (123) are furnished respectively on the same side of the two external hook parts (112), (122). Two upper openings (114), (124) are also furnished at the top part a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com