System and Method for Ultrasonic Sample Preparation

a technology of ultrasonic sample and preparation method, which is applied in the field of system and method of ultrasonic sample preparation, can solve the problems of significant drawbacks of the process, varies the amount of ultrasonic energy received in each sample well, and the energy transmitted by the ultrasonic probe into the liquid bath is not uniformly distributed throughout the bath

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

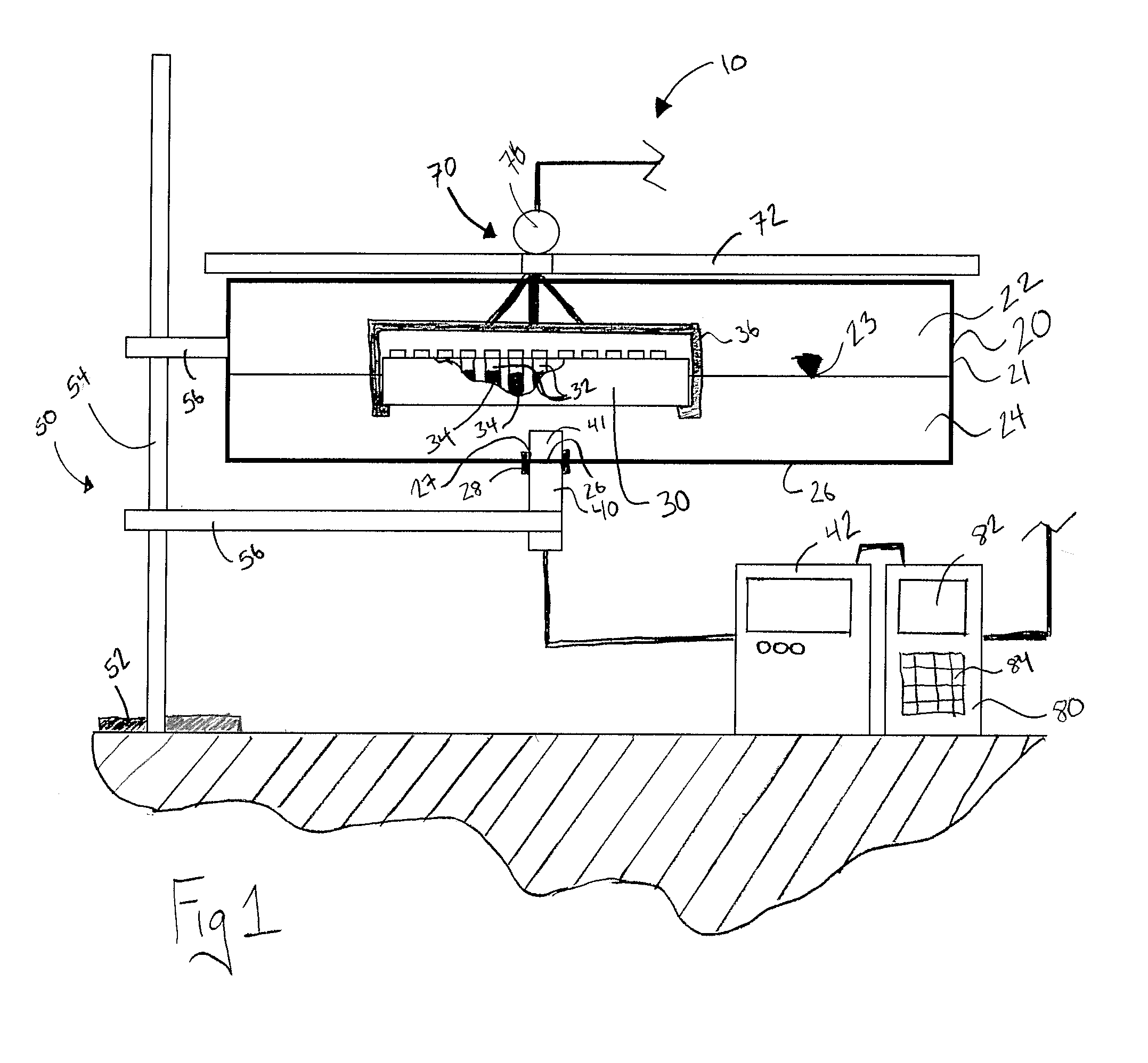

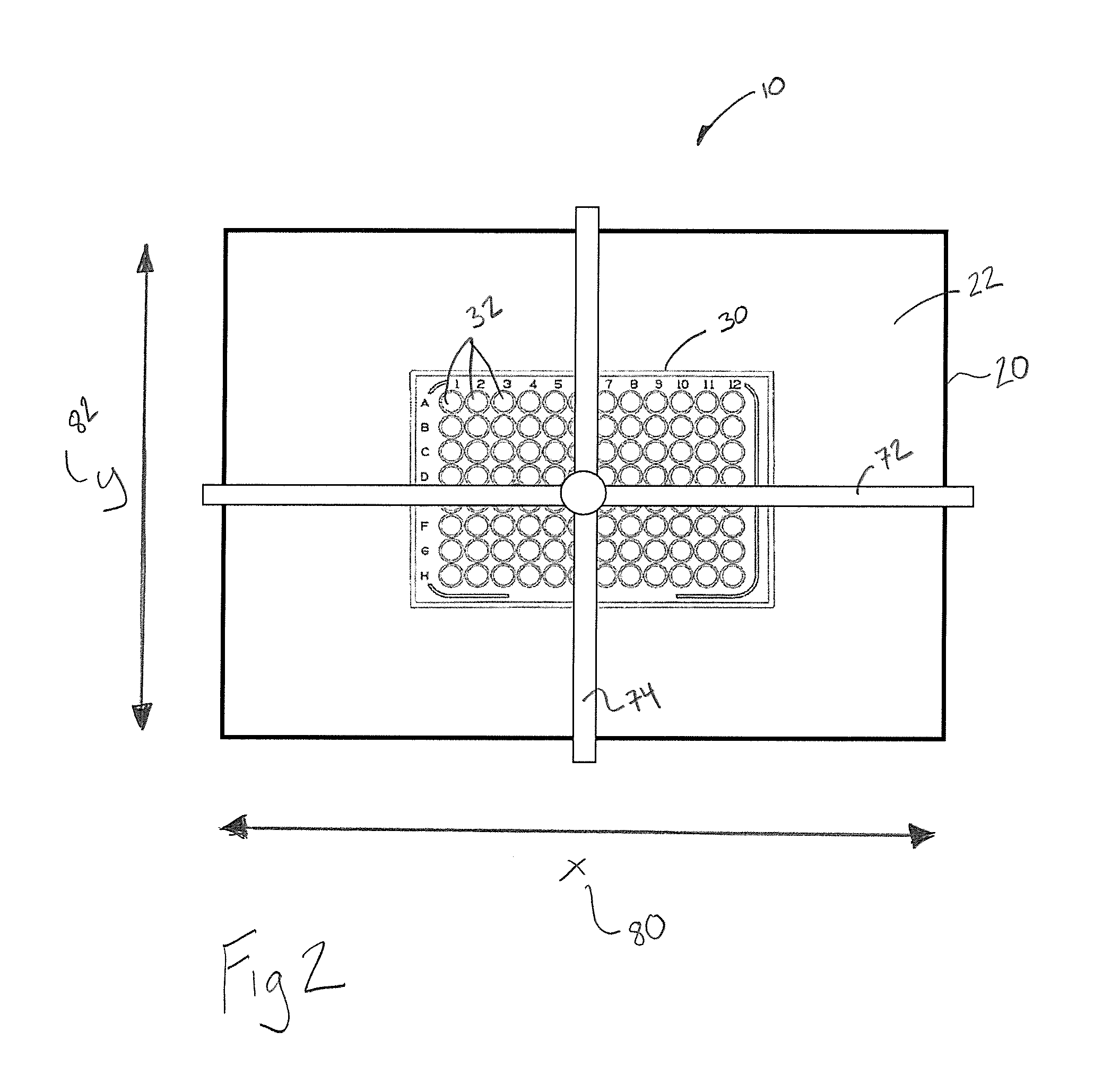

[0037]In reference to FIGS. 1-2, a system 10 for ultrasonic sample preparation is shown. The system 10 includes vessel 20. It should be noted that a front face of the vessel 20 is not shown in FIG. 1 in order to more fully illustrate the present invention through FIG. 1. The vessel 20 has a wall 21 that defines an inner volume 22. The inner volume 22 is configured such that a liquid 24 can be received and contained therein. In FIG. 1, liquid water 24 is received in the inner volume 22. It should be understood, however, that one or more different liquids may be received in the inner volume 22 of the vessel 20. The liquid 24 facilitates transmission of mechanical vibrations emitted from an ultrasonic probe 40 (discussed in detail below) to a sample 34 (discussed in detail further below).

[0038]The system 10 includes a microplate 30 disposed in the inner volume 22 of the vessel 20. The microplate 30, also known as a Microtitre plate or microwell plate, is a flat plate with multiple “sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com