Biorefinery system, methods and compositions thereof

a biorefinery and microorganism technology, applied in the field of bioengineering approaches, can solve the problems of high production cost, insufficient farm land available, and insufficient supply of biofuels to date to meet both global food and fuel needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

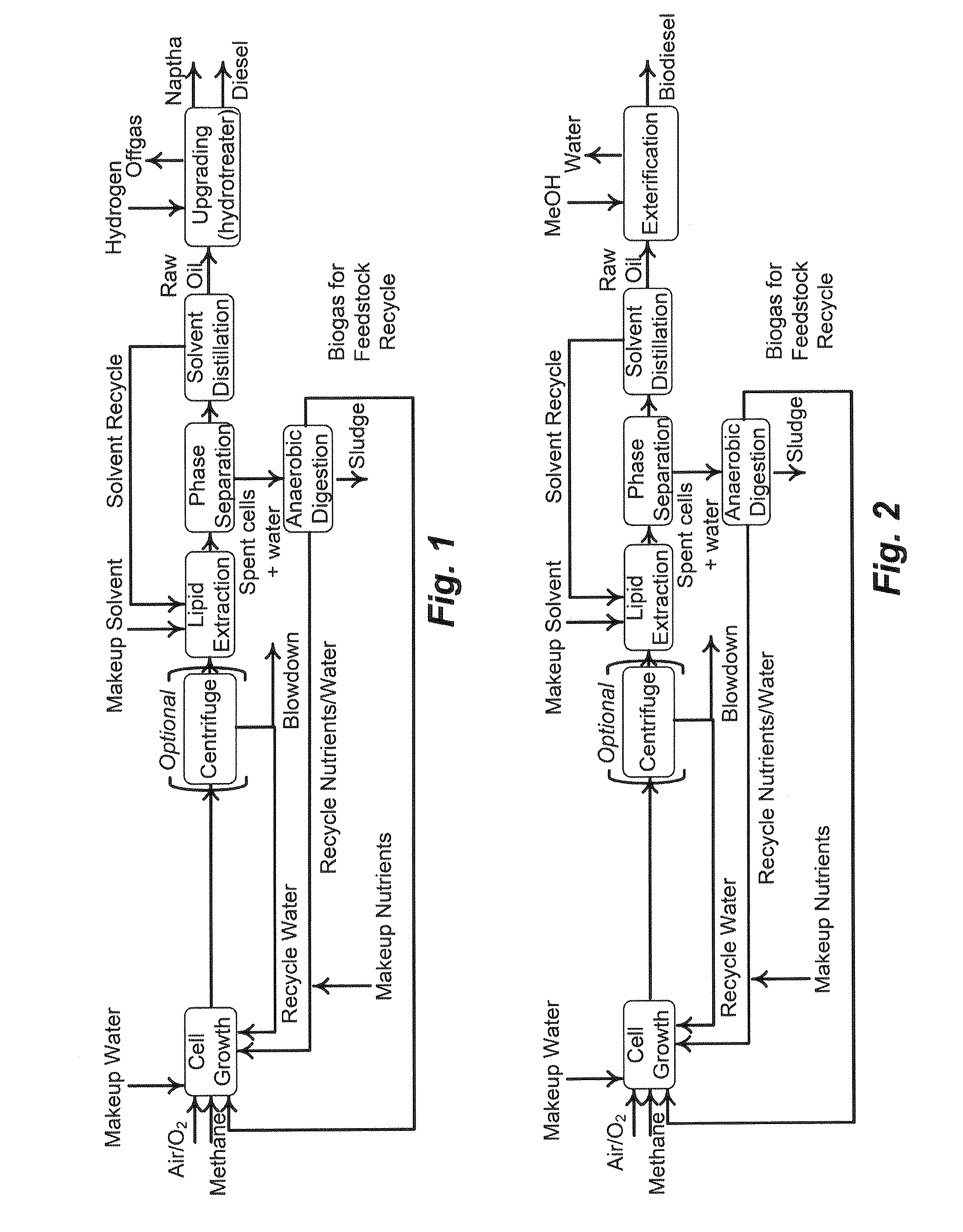

Exemplary Biofuel Production

Culture Maintenance

[0073]Methylosinus trichosporium OB3b was maintained at 30° C. in serum vials containing Higgins minimal nitrate salts medium (NSM). The headspace composition was adjusted to a 50:50 volume of methane:air. The vials were shaken at a rate of 200-250 rpm. Alternatively, the culture was maintained on NSM-media plates solidified with 1.5% w / v agar grown in the presence of methanol vapor (via 0.5 mL methanol in the lid of parafilm-sealed plates) or supplemented with 1% methanol. Plates were incubated inverted in a humidified chamber under normal atmosphere at 30′C.

Methanotroph Fermentation

[0074]A 2-liter bioreactor containing 1 L defined media MM-W1 was inoculated with cells from serum vial batch culture (10-20% v / v). The composition of medium MM-W1 was as follows: 0.8 mM MgSO4*7H2O, 10 mM NaNO3, 0.14 mM CaCl2, 1.2 mM NaHCO3, 2.35 mM KH2PO4, 3.4 mM K2HPO4, 20.7 μM Na2MoO4*2H2O, 1 μM CuSO4* 5H2O, 10 μM FeEDTA, and 1 mL trace metal solution (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| octane number | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com