Vacuum Cleaner

a vacuum cleaner and vacuum chamber technology, applied in the field of vacuum cleaners, can solve the problems of reducing the efficiency of dust separation, inconvenience for users, and limited space in the dust collection unit, and achieve the effect of convenient and fast dust compression operation and convenient emptying of the dust collection container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will now be described more fully with reference to the accompanying drawings, in which example embodiments are shown. However, this invention should not be construed as limited to the embodiments set forth herein. Disclosed features of example embodiments may be combined as readily understood by one of ordinary skill in the art to which this invention belongs. Throughout the following description similar reference numerals have been used to denote similar elements, parts, items or features, when applicable.

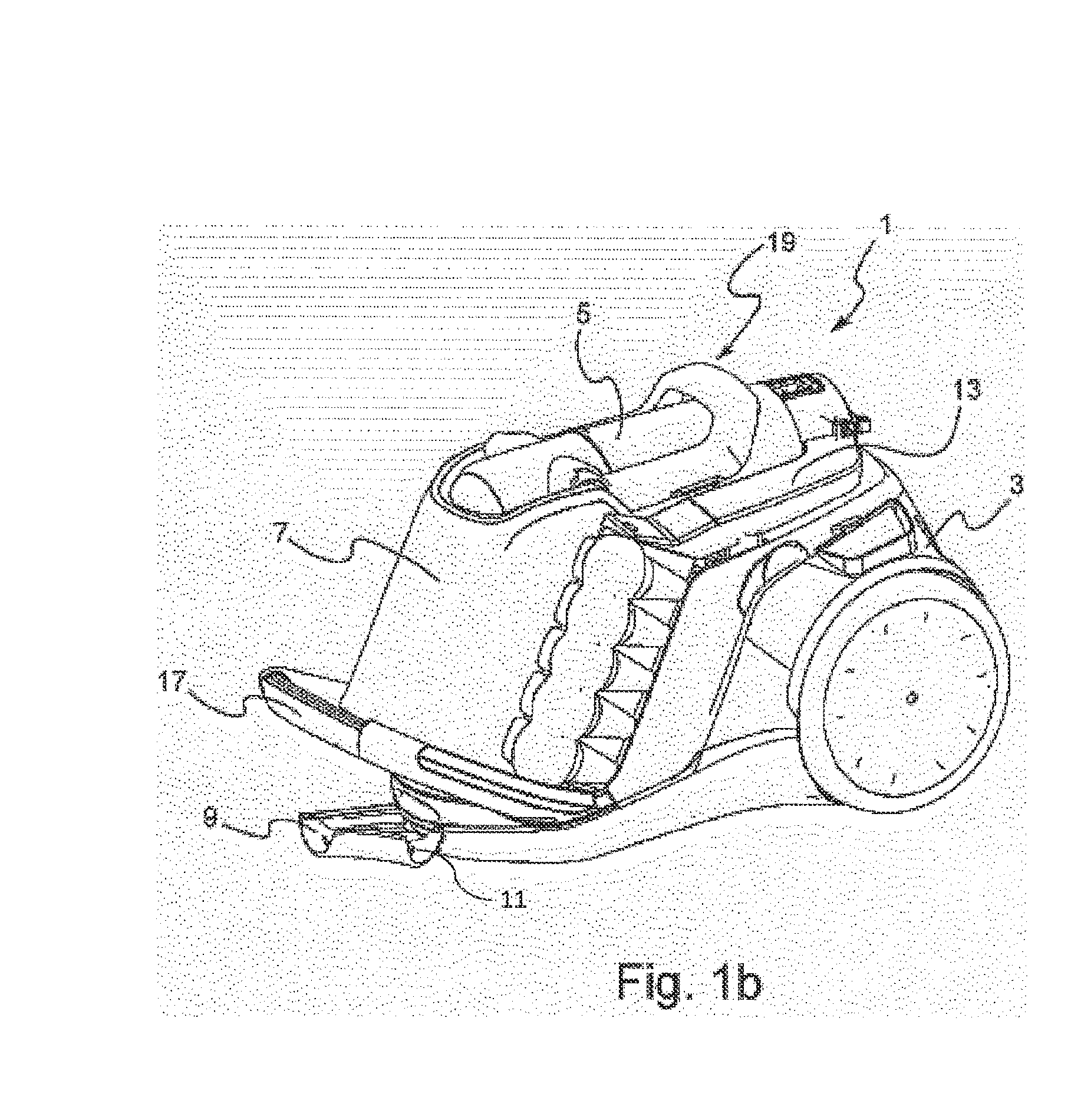

[0035]In FIGS. 1a and 1b a vacuum cleaner 1 according to embodiments are shown. The vacuum cleaner comprises a main body 3, a dust separating device 5 and a dust collecting container 7. A suction motor (not shown) is disposed in the main body for generating a suction force at an air inlet 9. A hose system and nozzle can be connected to the air inlet 9 for performing the cleaning. Basically, any known hose system and nozzle is feasible.

[0036]From the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com