Pumping system for evacuating gas from a plurality of chambers and method for controlling the pumping system

a technology of pumping system and gas evacuation chamber, which is applied in the direction of pump control, non-positive displacement fluid engine, pump control, etc., can solve the problems of only being able to adapt the noise reduction to existing possibilities, increasing the energy consumption and associated, and reducing the efficiency of the pumping system, so as to achieve simple throttle orifice, simple structure, and constant throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

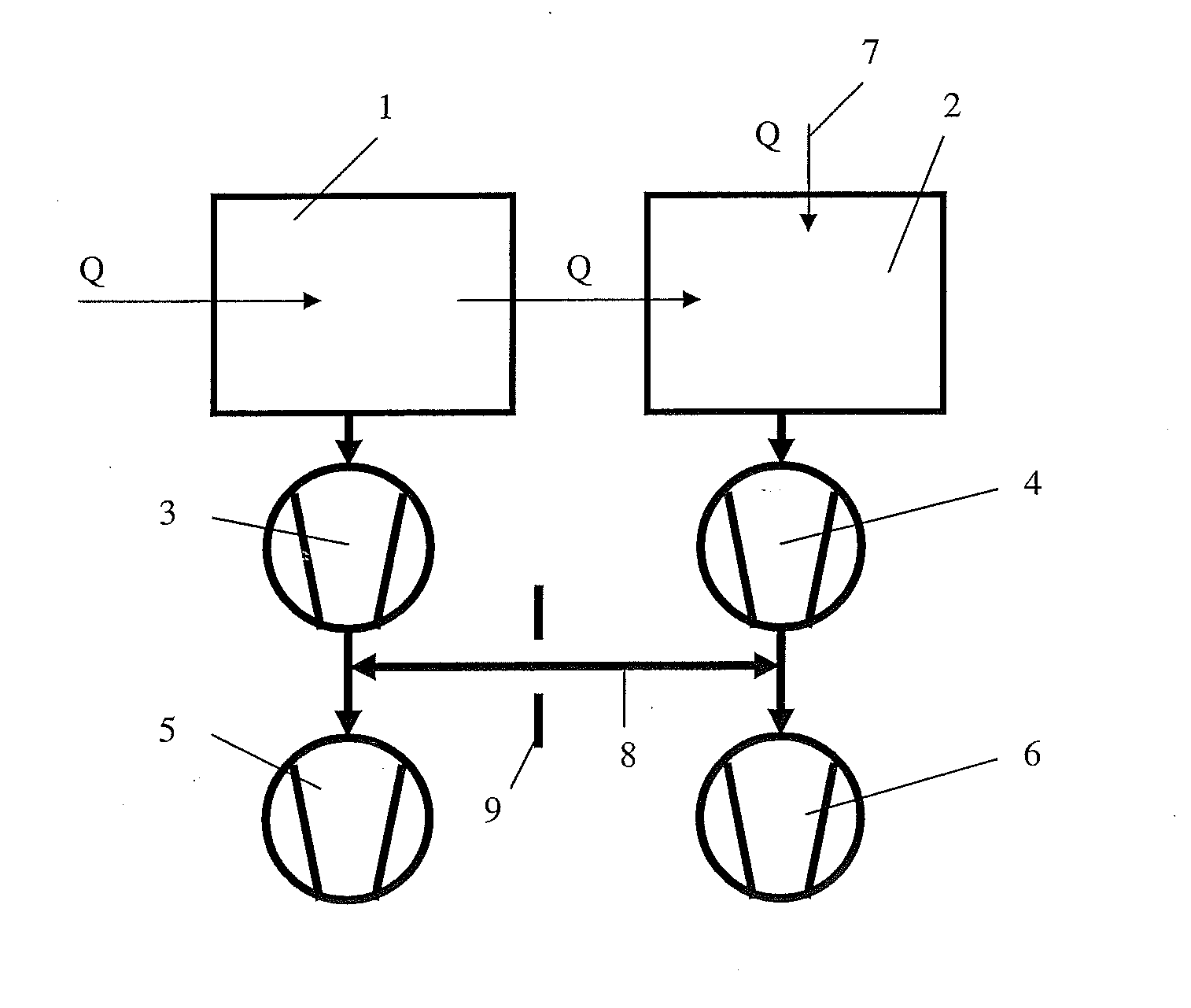

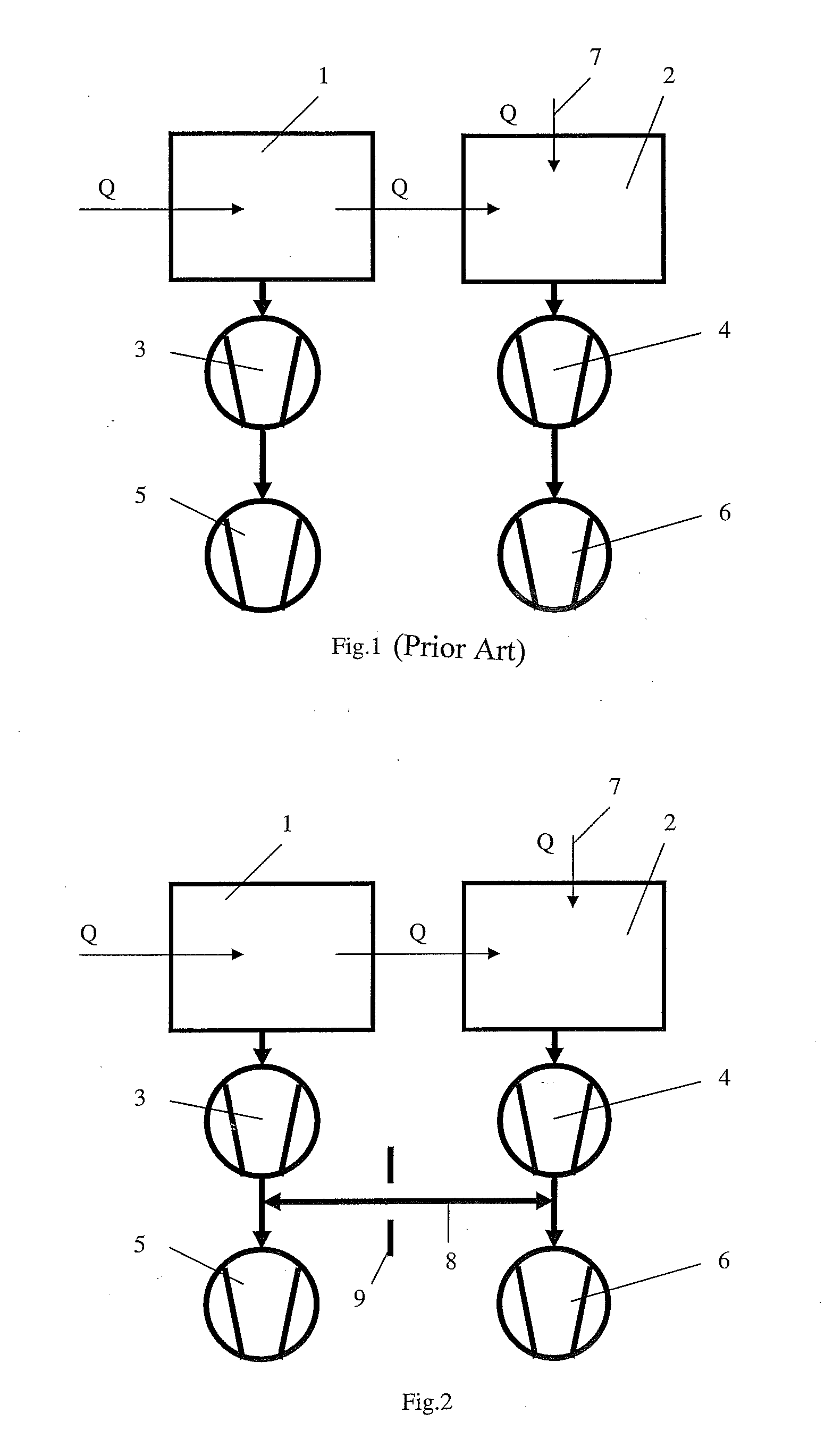

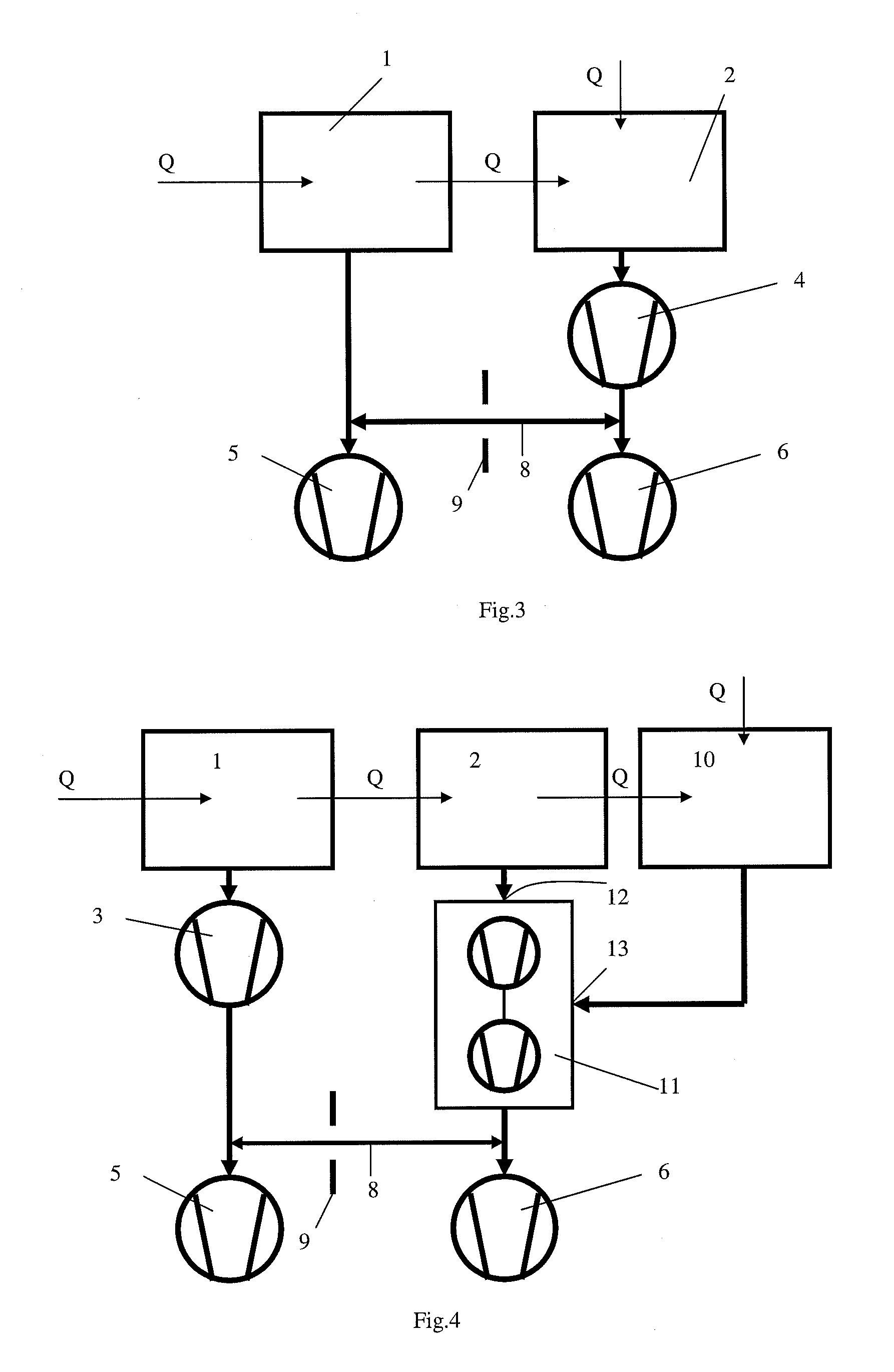

[0037]FIG. 1 shows a prior art pumping system that has two to-be-evacuated chambers 1 and 2. A turbomolecular pump 3 is associated with the chamber 1, and a turbomolecular pump 4 is associated with the chamber 2.

[0038]The turbomolecular pump 3 is supported by a fore-vacuum pump 5, and the turbomolecular pump 4 is supported by fore-vacuum pump 6. The drawback of the prior art pumping system consists in that the turbomolecular pump 3 should maintain a predetermined pressure in the chamber 1, and the turbomolecular pump 4 should maintain a predetermined pressure in the chamber 4. Accordingly, the pumps 3, 4, 5, 6 should be correspondingly capable of performing this task. This means that they must have a required pumping capacity under network voltage and frequency condition for a particular region.

[0039]Q designates a gas flow. The chambers 1 and 2 are connected with each other. With different pressures in chambers 1 and 2, there exists a gas flow Q between the two chambers. In the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com