Cushion structure for vehicle seat

a vehicle seat and cushion structure technology, which is applied in the direction of vehicle components, vehicle arrangements, chairs, etc., can solve the problems of giving discomfort to the seated occupant of the vehicle, the hardness cannot be adjusted once the cushion foam is formed, etc., and achieves the effect of suppressing the local action, reducing the strength of the cushion pan (3), and reducing the tension of the band (41) consisting of a flexible material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

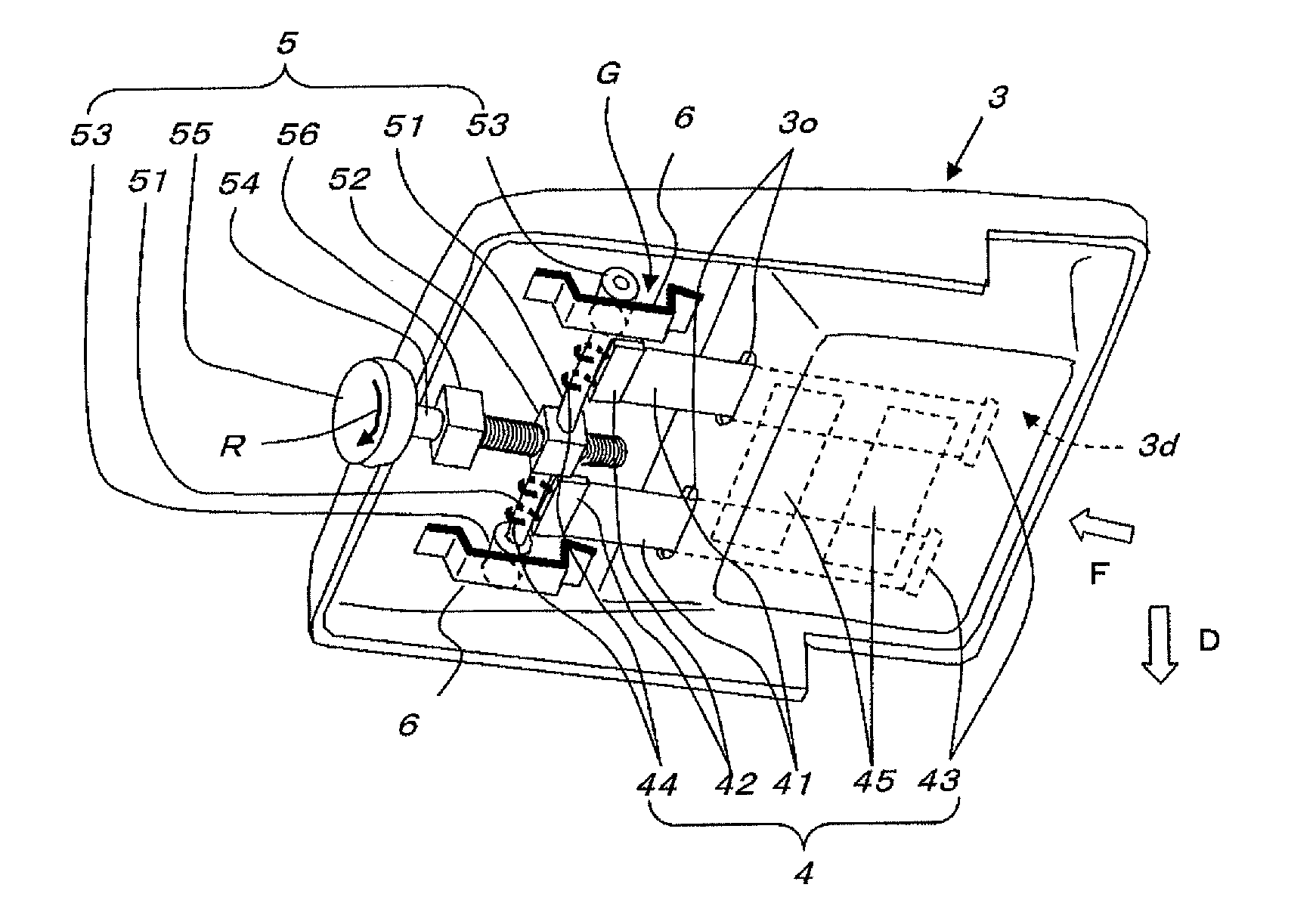

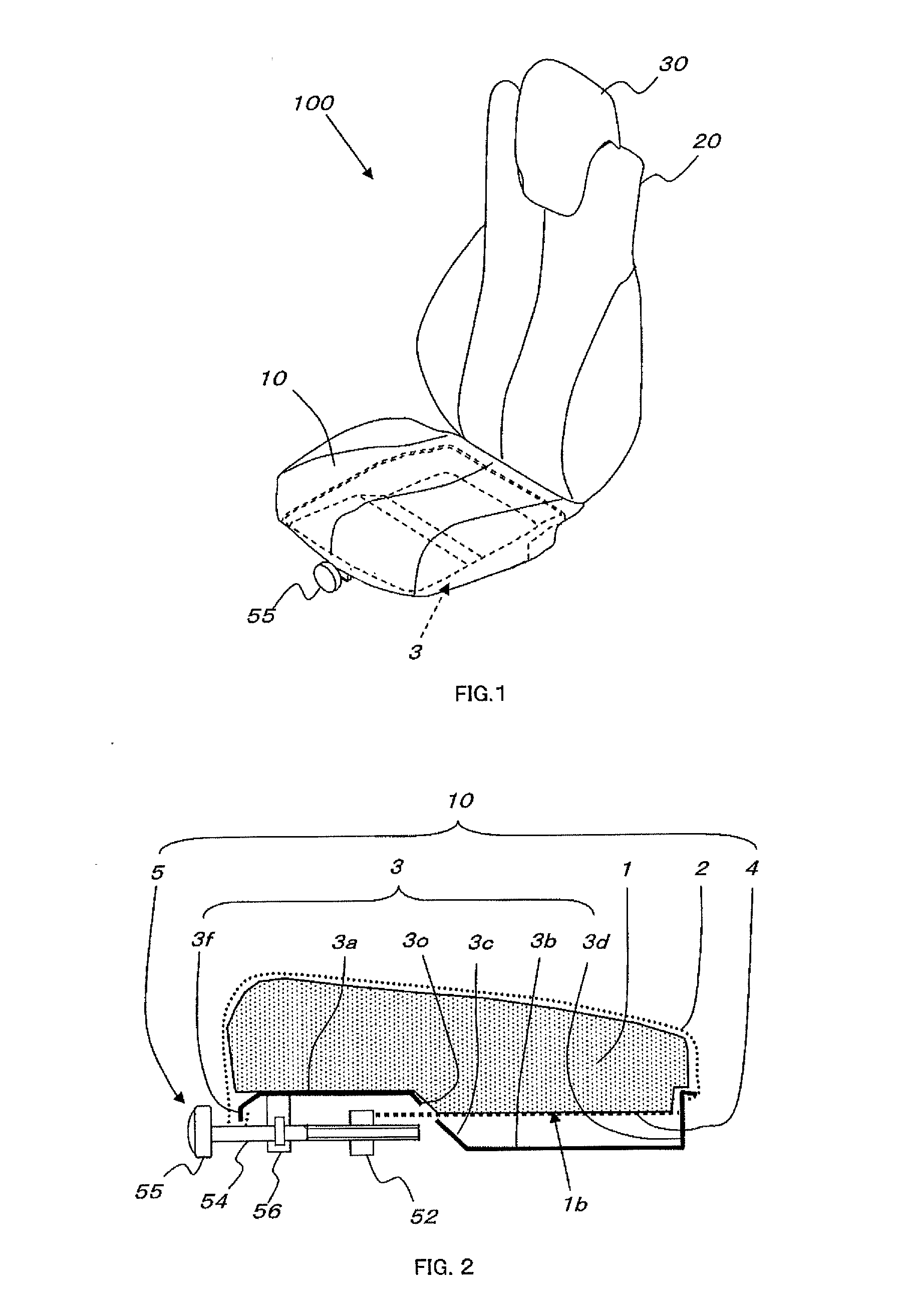

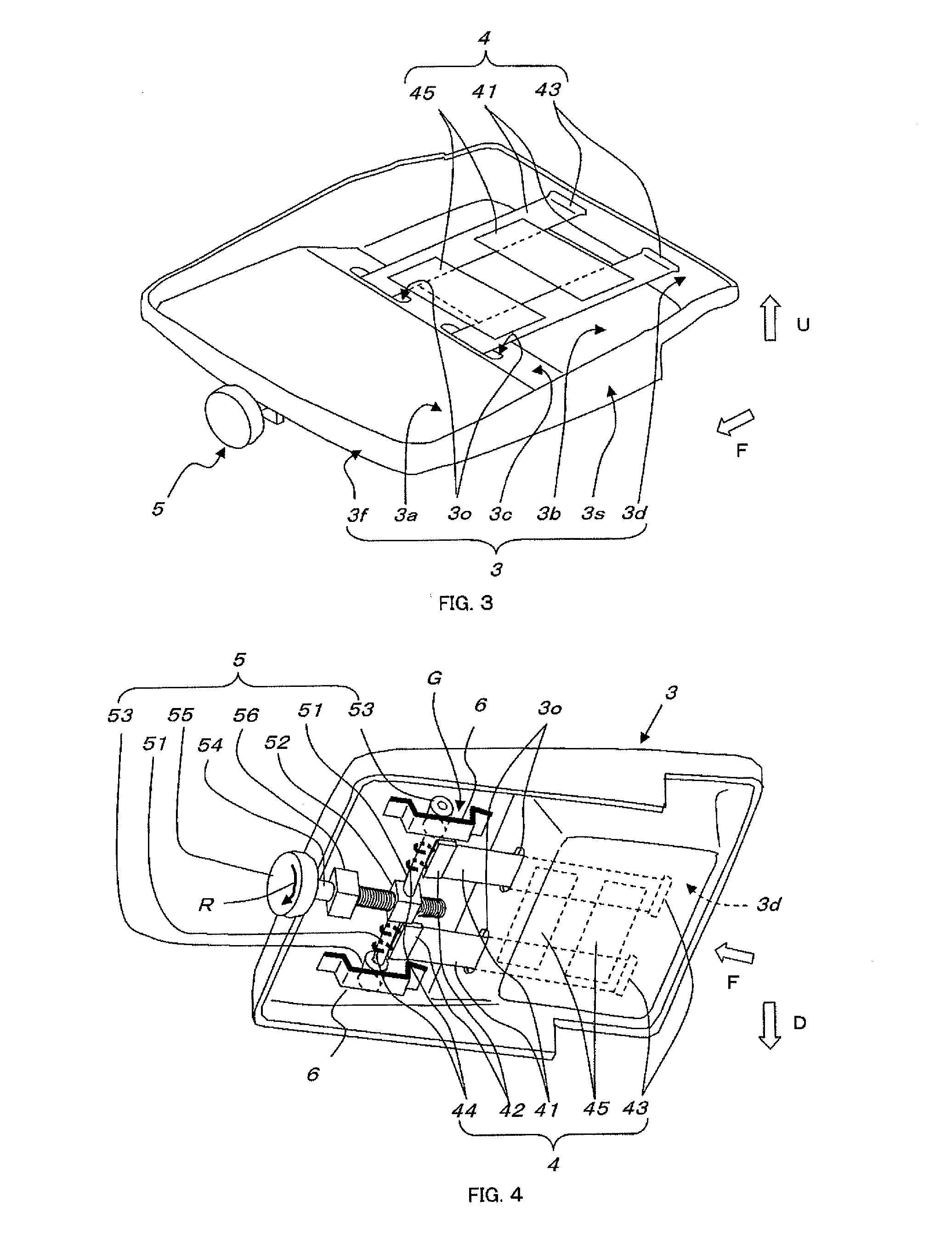

first embodiment

[0037]FIG. 7 shows the seat cushion 10 of the first embodiment in a situation that the hardness of the seat cushion 10 is increased. FIG. 7 shows the situation, for example, when the occupant has just seated and the vehicle is still in the stationary state. In the situation shown in FIG. 7, the tension acted on the band 4 consisting of a flexible material (the band body 41) is strong and the band 4 is not deflected generally.

[0038]FIG. 8 shows the situation that the hardness of the cushion seat 10 is decreased by operating (turning) the adjusting dial 55 of the seat cushion 10 shown in FIG. 7. Or, it shows the bounding situation of the vehicle in a manner that the hardness of the cushion seat 10 is decreased. In the situation shown in FIG. 8, the tension acted on the band consisting of a flexible material (band body 41) which supports the bottom 1b of the cushion foam 1 is small, and the cushion foam 1 and the band 4 deflect downward. In the state shown in FIG. 8, for example, even ...

third embodiment

[0051]In the third embodiment shown in FIG. 10, when the adjusting dial 55 is turned in the direction of arrow R1, the hook support rod 51B turns in the direction of arrow R2. Then, the band body 41B is wound up by the hook support rod 51B and the tension of the band 4B consisting of a flexible material (band body 41) is increased. On the other hand, if the adjusting dial 55 is turned in reverse direction, the tension of the band 4B consisting of a flexible material (band body 41) is decreased.

[0052]The constructions and the functional effects of the third embodiment, which are not mentioned above, are the same as that of the first embodiment.

[0053]The embodiments shown in the drawings are merely examples and are not intended to restrict the technical scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com