Screwdriver hanging assembly

a screwdriver and assembly technology, applied in the field of screwdriver hanging assembly, can solve the problems of increased manufacturing cost and inconvenience, and achieve the effect of saving time for assembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

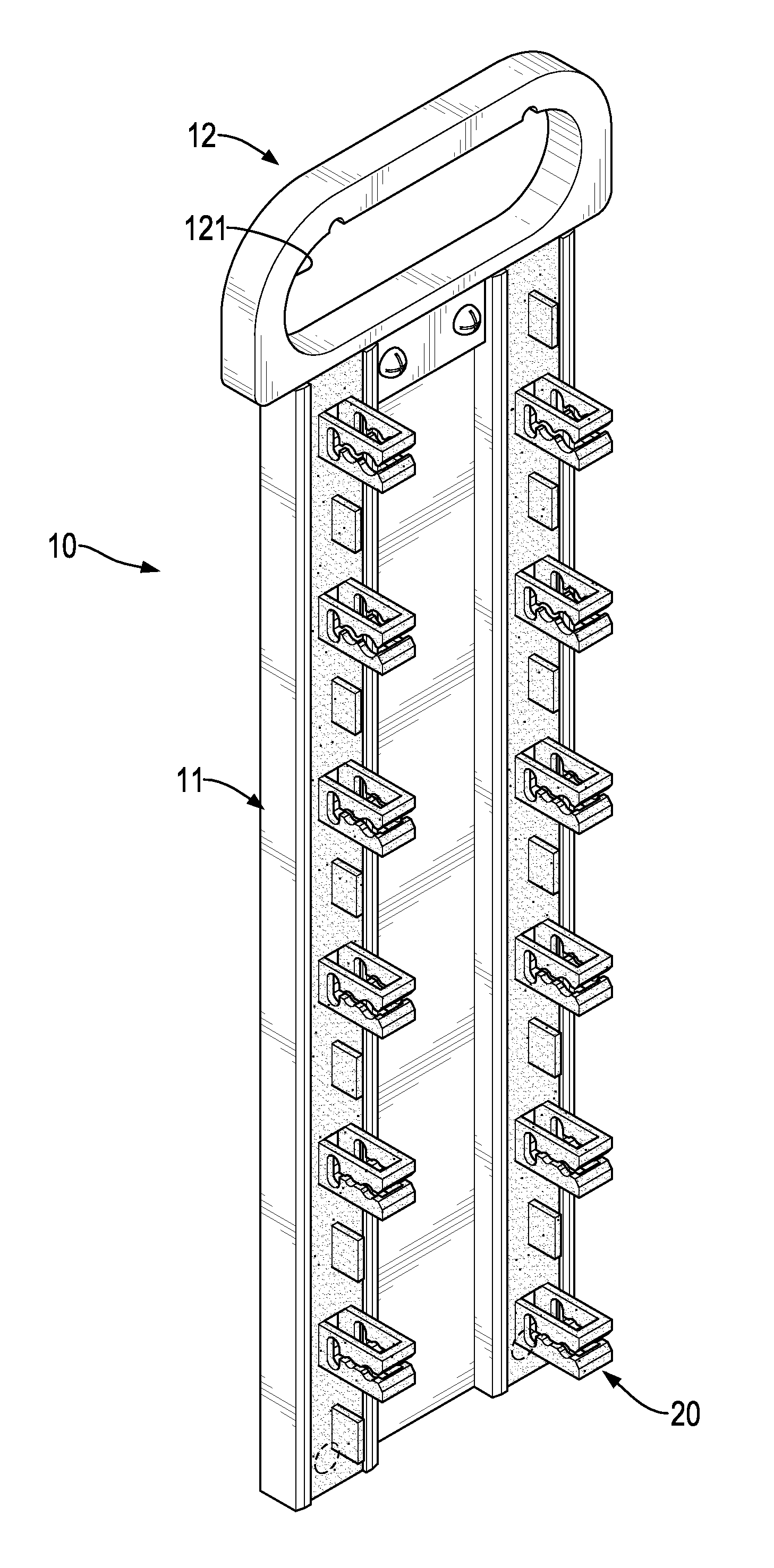

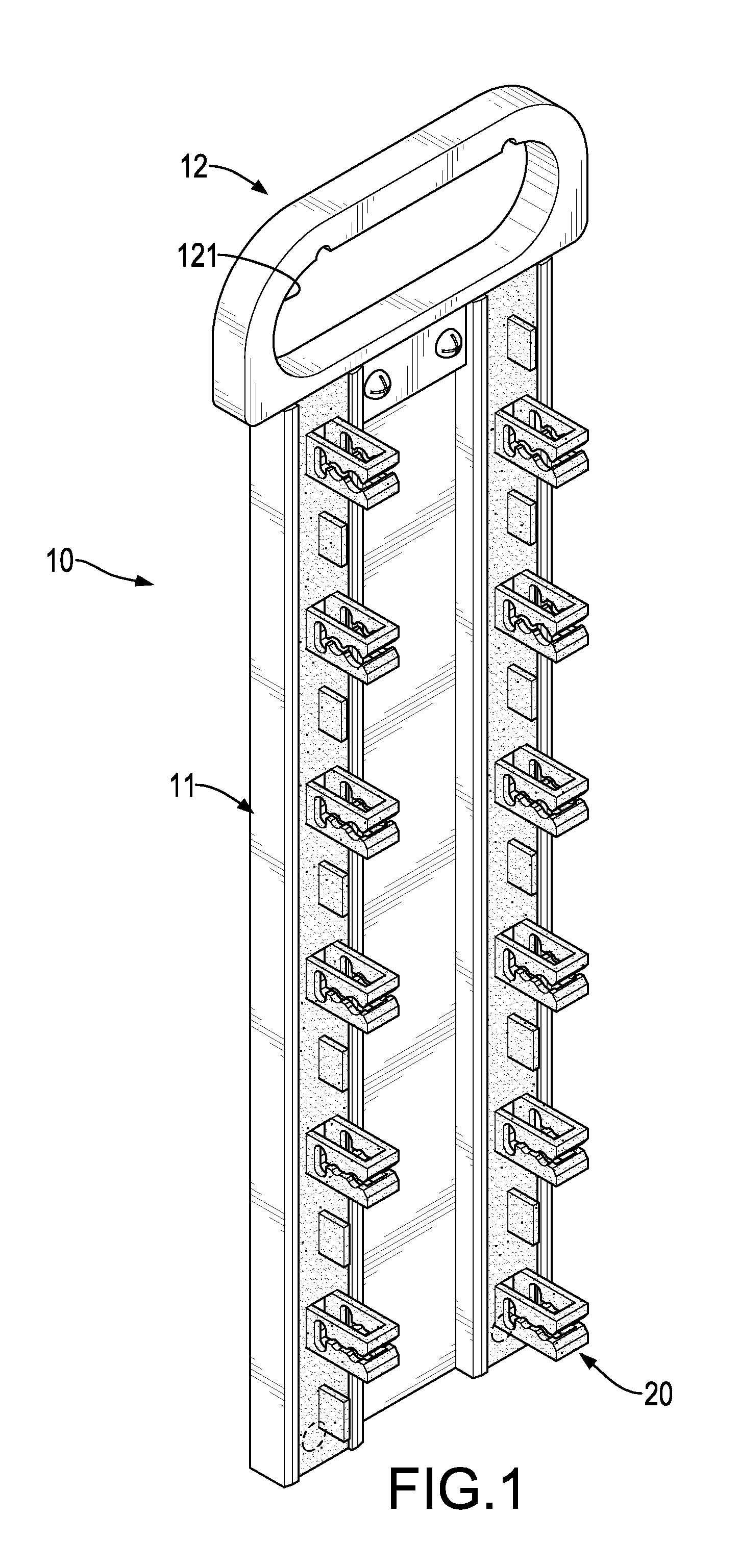

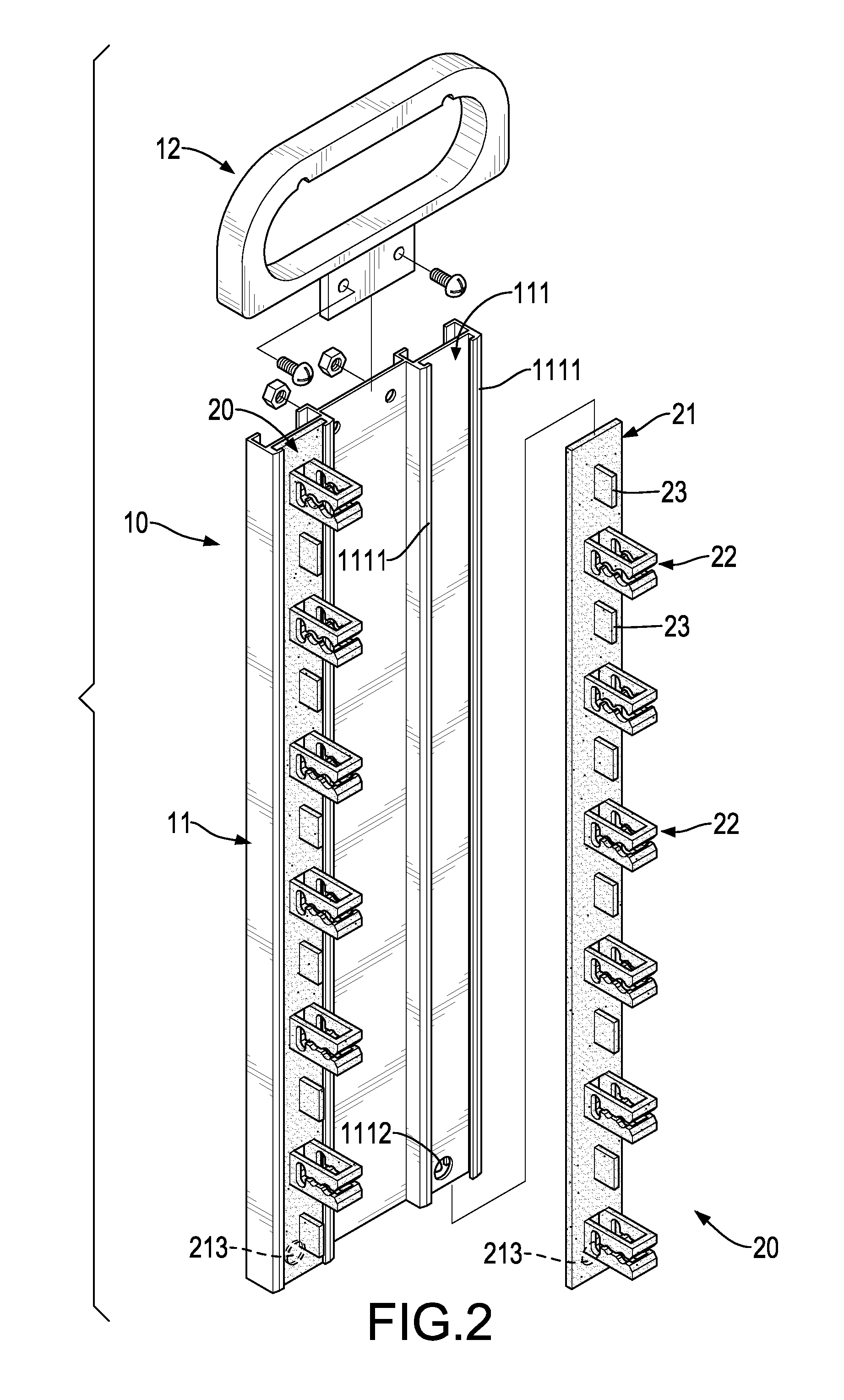

[0028]With reference to FIGS. 1 and 2, a screwdriver hanging assembly in accordance with the present invention comprises a main frame 10 and two connecting devices 20.

[0029]With reference to FIGS. 1, 2 and 5, the main frame 10 has a main plate 11 and a hanging plate 12. The main plate 11 has a rectangular cross section and has two track grooves 111. The track grooves 111 are longitudinally elongated and are parallel to each other. Each track groove 111 has two edges, a bottom, two opposite inner surfaces, two strips 1111 and a positioning hole 1112. The edges of each track groove 111 are longitudinally elongated. A distance between the inner surfaces of each track groove 111 is defined as a first width A.

[0030]The two elongated strips 1111 of each track groove 111 are longitudinally elongated, are parallel to each other and are respectively and integrally connected with the edges of the track groove 111. A distance between the strips 1111 of each track groove 111 is defined as a sec...

second embodiment

[0046]the screwdriver hanging assembly does not have the enlarged holes 221, the first shank holes 222, the second shank holes 223, the bracket openings 224 and the chunks 23. Each bracket 22C has a slot 226C and a through hole 227C. The slot 226C of each bracket 22C is elongated, is formed through the bracket 22C and has a central segment. The through hole 227C of each bracket 22C is formed through the bracket 22C at the central segment of the slot 226C, communicates with the slot 226C and has a round cross section.

[0047]Each connecting device 20C has multiple spaces 24C formed between the brackets 22C of the connecting device 20C at intervals, wherein the spaces 24C of the first connecting device respectively align with the brackets 22C of the second connecting device and the brackets 22C of the first connecting device respectively align with the spaces 24C of the second connecting device.

[0048]With reference to FIGS. 15 to 18, accordingly, a distal tip of a shank S1 of a screwdri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com