Adjusting rigid foil spar system

a rigid foil and spar system technology, applied in the field of rigid foil sails for boats, can solve the problems of reducing the efficiency of a conventional sail, so as to achieve the effect of easy adjustment of camber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

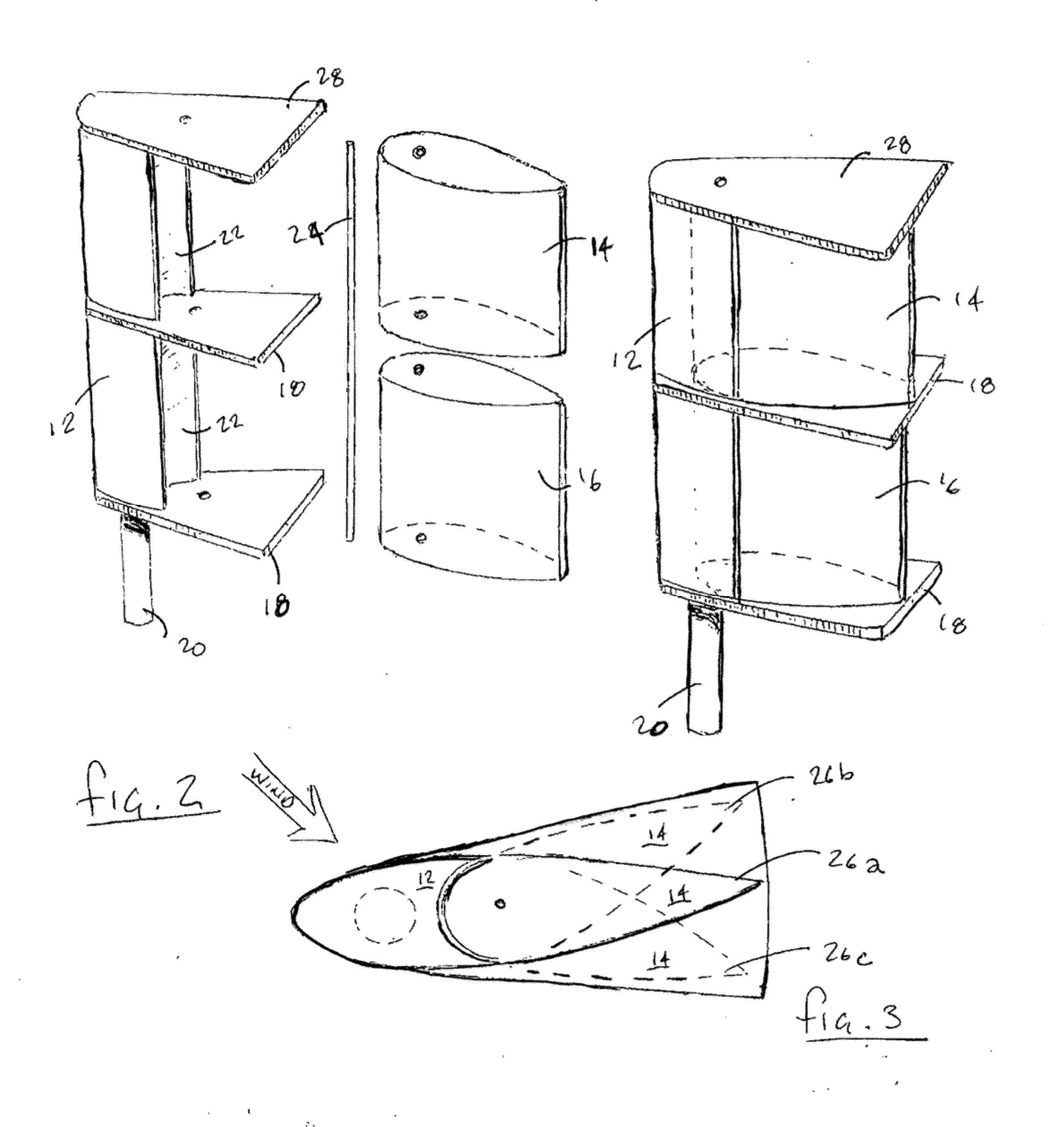

[0022]Now referring to the drawings, the three dimensional rigid foil sail design is generally shown and illustrated at 10. As can be seen at FIG. 1, the present invention generally provides at least a three part rigid foil sail 10 having a full length vertical leading edge 12 whose trim angle / angle of attack is controlled by the main sheet and at least two trailing edge flaps 14, 16 attached rearwardly of the leading edge 12, each of which can be independently trimmed from a convenient deck level control tray to achieve easily adjustable camber. Further, the rigid foil sail 10 can be seen to include control trays 18 at the bottom of each of the trailing edge flaps 14 and 16 that allow independent adjustment of the camber for each section of the rigid foil sail 10 independently of one another.

[0023]It can be seen from FIG. 1 that the rigid foil sad 10 provides a squared geometry as compared to the prior art sails. Such squared geometry can be achieved due to the rigid nature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com