Bone cement and a method for producing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

EXAMPLE 1

[0066]As a first step, an acrylate-based bone cement composed of a monomer and a polymeric bone cement powder are mixed. A bone cement paste is formed in this way, as it can be used according to the prior art.

[0067]After mixing this paste, another paste that is composed of a suspension of finely dispersed, distributed particles of hydroxyapatite, calcium carbonate, calcium sulfate and / or calcium phosphate are mixed and combined with the bone cement in a suitable mixing device.

[0068]The paste that forms from the two pastes can now be used.

[0069]Instead of first producing the paste from acrylate-based bone cement in a separate step, a concentrated suspension containing hydroxyapatite, calcium carbonate, calcium sulfate and / or calcium phosphate can also be mixed directly with the polymer particles of the acrylate-based bone cement and the monomer.

Example

EXAMPLE 2

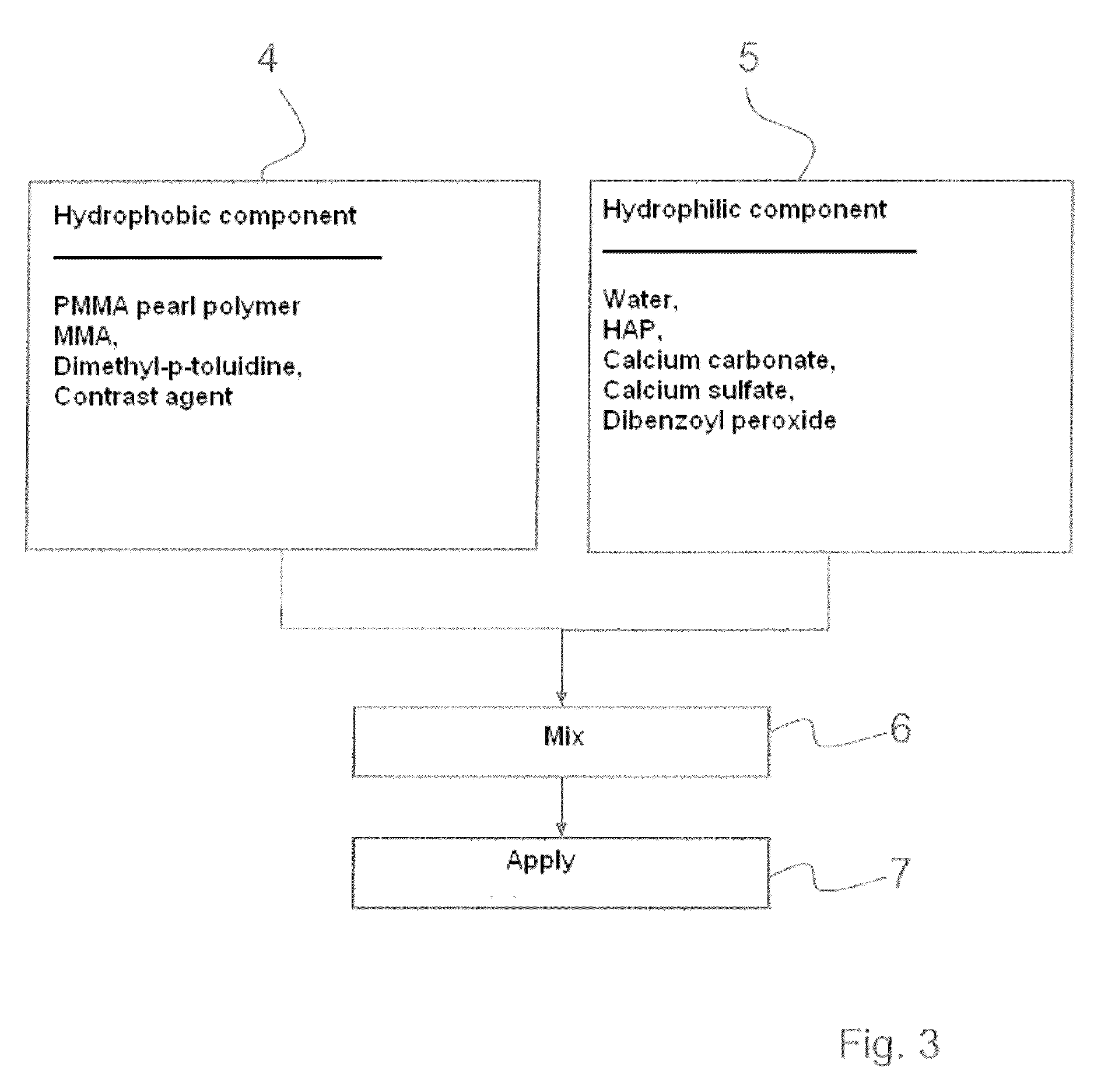

[0070]In a first step, a paste composed of an aqueous phase and finely dispersed, distributed particles of hydroxyapatite, calcium carbonate, calcium sulfate and / or calcium phosphate and dibenzoyl peroxide is mixed with a second paste. Optionally, a pharmacologically effective substance [is added]*. The second paste contains methyl(meth) acrylate and / or butyl acrylate as the monomer, dimethyl-p-toluidine as an accelerator and optionally, an x-ray contrast agent. Further, the second paste contains a partially cross-linked PMMA pearl polymer. The two pastes are mixed by means of a suitable mixer with or without a statistical mixing element and can then be introduced into defect sites by means of a syringe or by hand. *Text given in brackets does not appear in the original German text, but is added for clarity.—Translator's note.

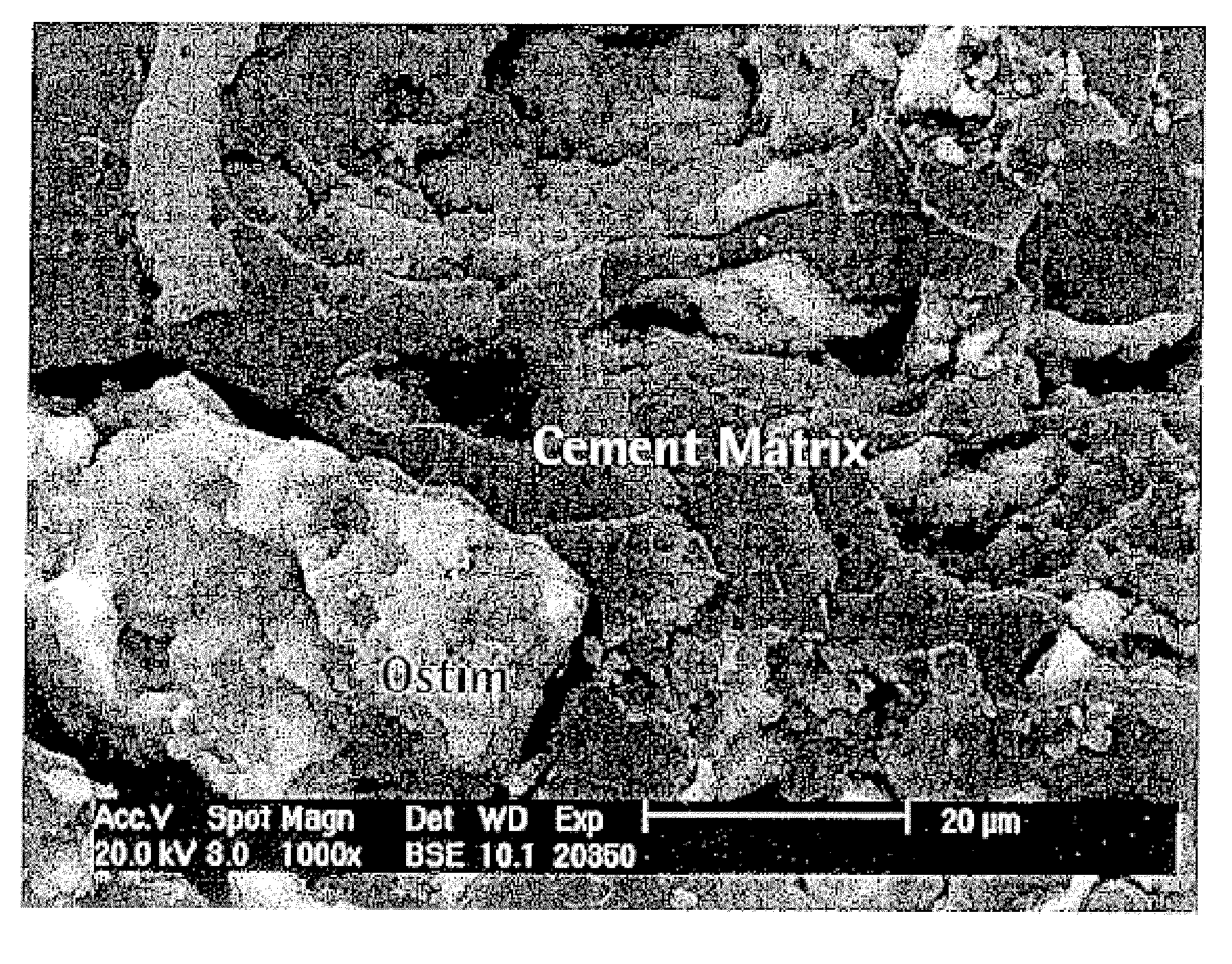

[0071]Due to the methyl methacrylate, the PMMA contained in the pearl polymer partially dissolves out from the beads or the beads swell and the otherw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com