Steel rail clip assembly

a technology of steel rail and assembly, which is applied in the direction of track superstructure, construction, and transportation, etc., can solve the problems of reducing the practical value of the steel rail clip assembly in use, affecting the safety of people on the train, and unable to prevent loosening of the clip, so as to reduce the risk of related property loss and injury, and the effect of not being easily removed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

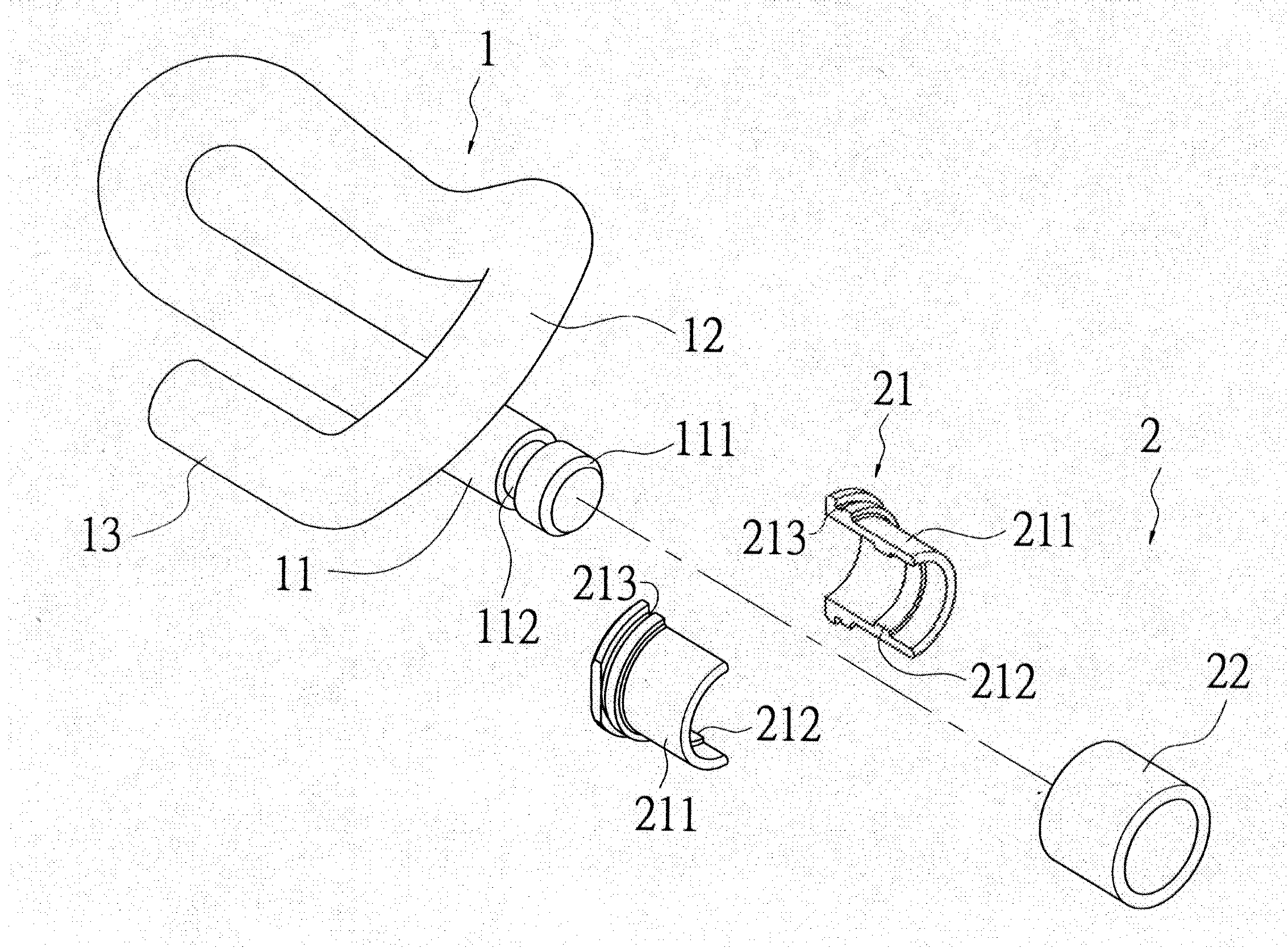

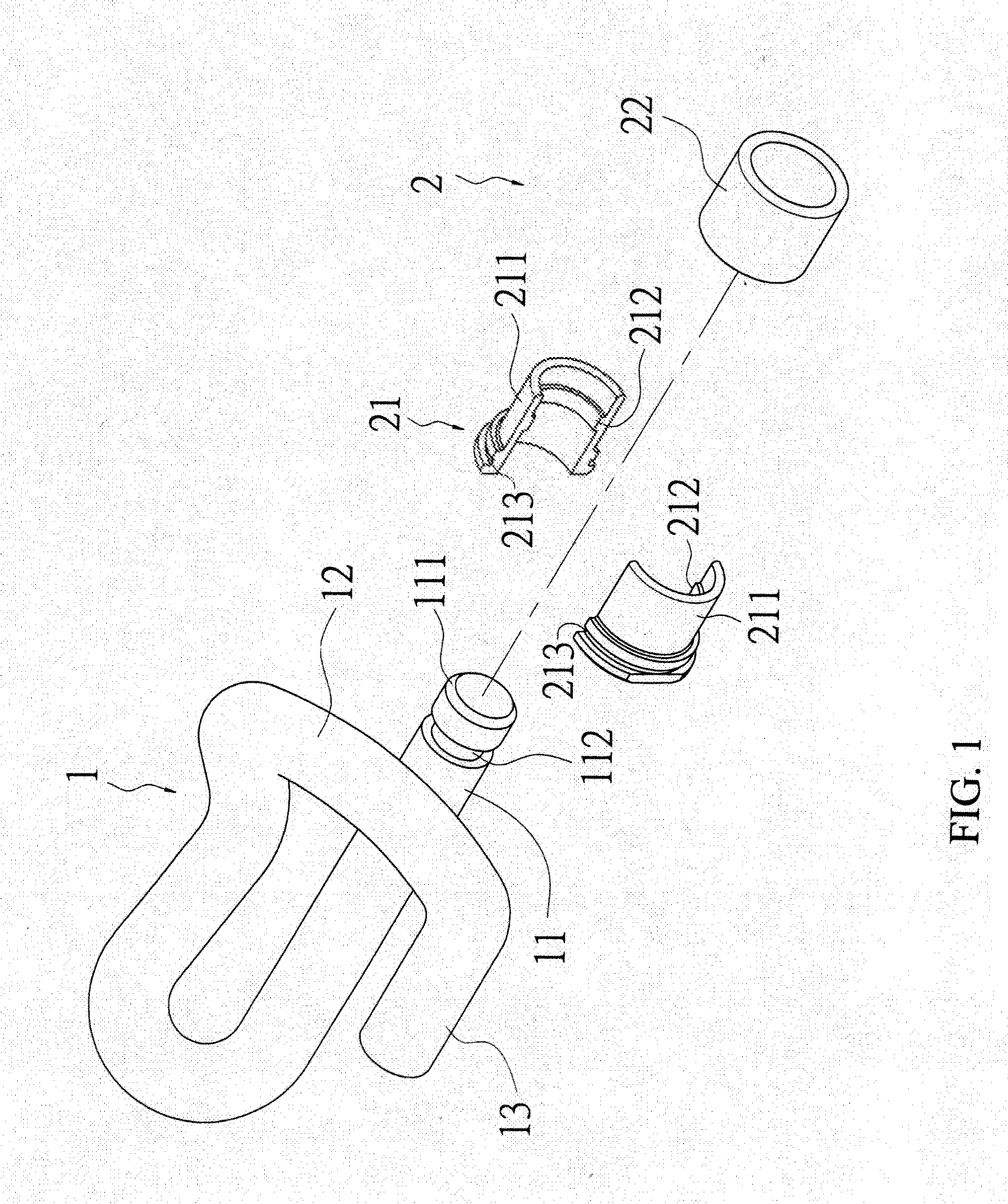

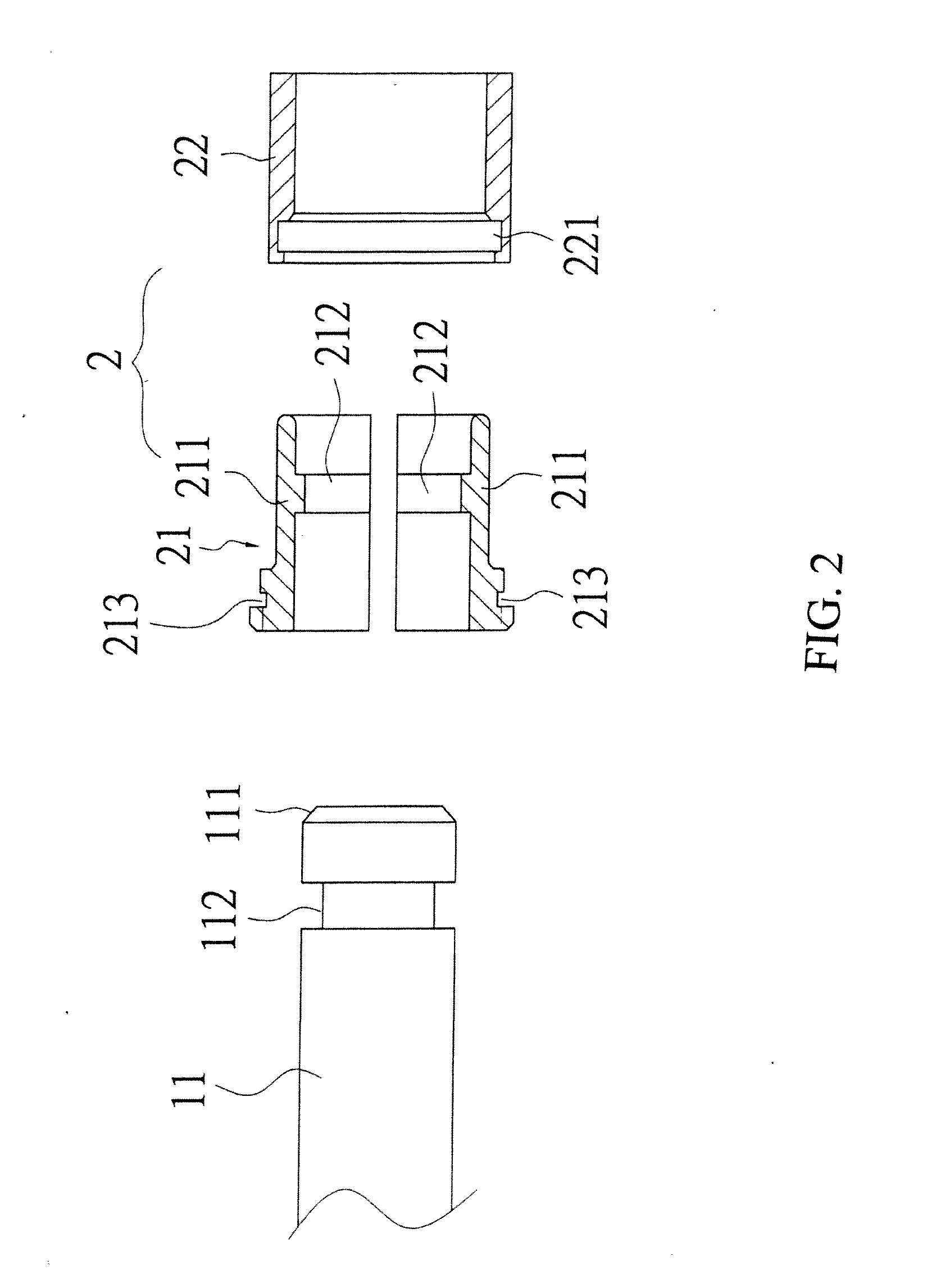

[0020]Refer to FIG. 1 and FIG. 2, an explosive view and a partial, enlarged, cross sectional view of an embodiment according to the present invention are revealed. An embodiment of a steel rail clip assembly mainly includes a clip 1 and a locating member 2.

[0021]With reference of FIG. 3, the clip 1 that looks like the letter “e” or “PR” viewed from a certain angle is formed by a bent metal bar. The clip 1 consists of at least one straight insertion rod 11, a cross part 12 bending from one side of the insertion rod 11 to the other side of the insertion rod 11, and a press part 13 connected with the cross part 12. The lowest portions of the clip 1 are positioned on two sides of the cross part 12. Moreover, no matter viewed from the top side or the bottom side, the cross part 12 crosses both sides of the insertion rod 11. A bevel 111 is formed on an outer end of the insertion rod 11 and a locating slot 112 is mounted concavely on an outer edge of the insertion rod 11.

[0022]The locating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com