Tie strap structure

a technology of tie straps and straps, which is applied in the direction of hose connections, flexible elements, packaging, etc., can solve the problems of inability to reuse tie straps, increase costs, waste of resources, etc., and achieve excellent security in use, convenient use, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

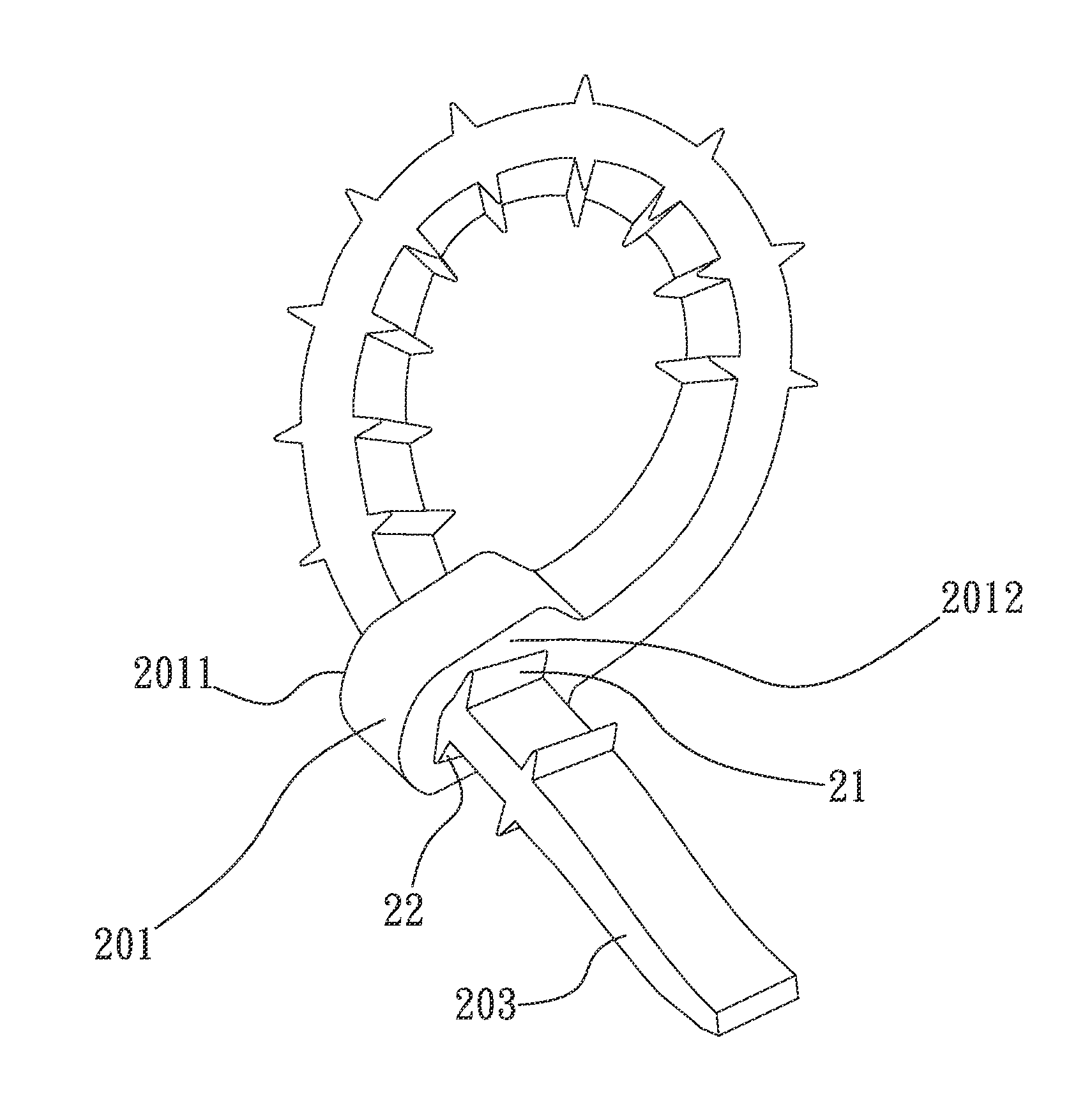

[0029]Please refer to FIGS. 2A and 2B, which show a first embodiment of the tie strap structure of the present invention. The tie strap structure includes at least one first raised section 21, at least one second raised section 22 and a elastic main body 2. The elastic main body 2 has an anchor section 201 and an insertion section 203. The anchor section 201 has a first abutment side 2011, a second abutment side 2012 opposite to the first abutment side 2011 and a through hole 2013. The through hole 2013 has, but not limited to, an elliptic configuration for illustration purposes only. Alternatively, the through hole 2013 can have a rectangular configuration, circular configuration or any other suitable configuration. The through hole 2013 is positioned between the first and second abutment sides 2011, 2012 for the insertion section 203 to correspondingly insert therethrough.

[0030]The anchor section 201 has an elliptic configuration or any other suitable configuration such as a recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com