Peristaltic Pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

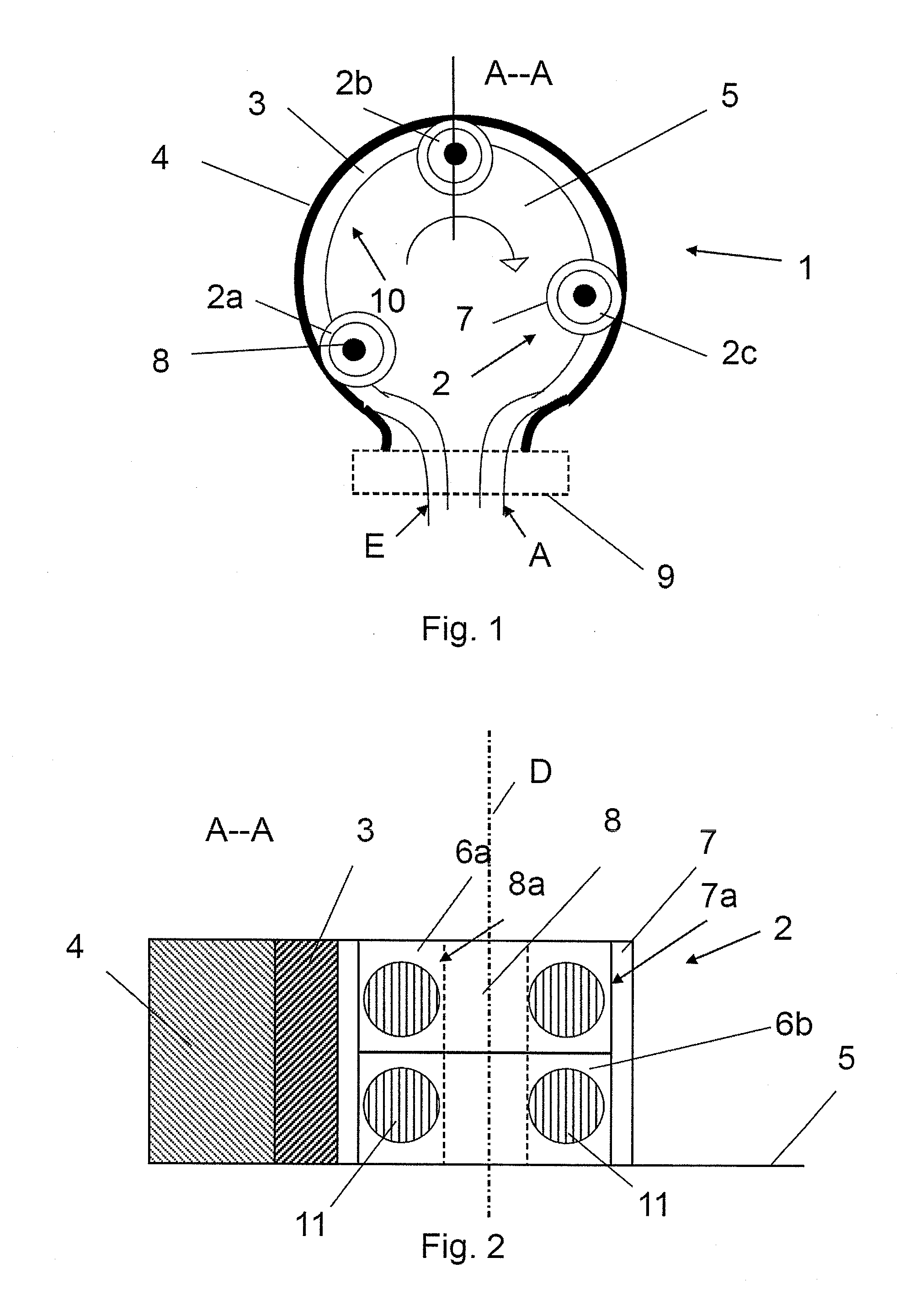

[0009]FIG. 1 shows a peristaltic pump 1 for conveying fluids. The peristaltic pump comprises a stator 4, in which a flexible hose 3 is integrated over a substantially circular path (approximately 360°). As is illustrated in FIG. 1 by the arrow, a rotor 5 is supported in the stator 4. The rotor has radially arranged conveying elements 2a, 2b, 2c. The conveying elements 2a, 2b squeeze the hose 3 in the section 10. A motor, not illustrated in greater detail, cooperates with the rotor 5 and, in particular, moves the squeezed fluid section 10 progressively in the hose 3 in accordance with the direction of the arrow. The fluid is thus conveyed in the section 10 from the inlet E of the peristaltic pump 1 to the outlet A of the pump 1. Of course, conveyance may also occur in a direction opposite that of the arrow. In this case the peristaltic pump 1 may be used both for pumping and for suction.

[0010]The hose 3 is fixed in a hose clamp 9 in the region of the inlet E and of the outlet A of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com