Modular Thermal Energy Retention and Transfer System

a technology of thermal energy storage and transfer system, applied in the field of modules, can solve the problems of increasing the cost of energy production, driving the capital expenditure of energy production, and increasing the economic demand for consumable energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

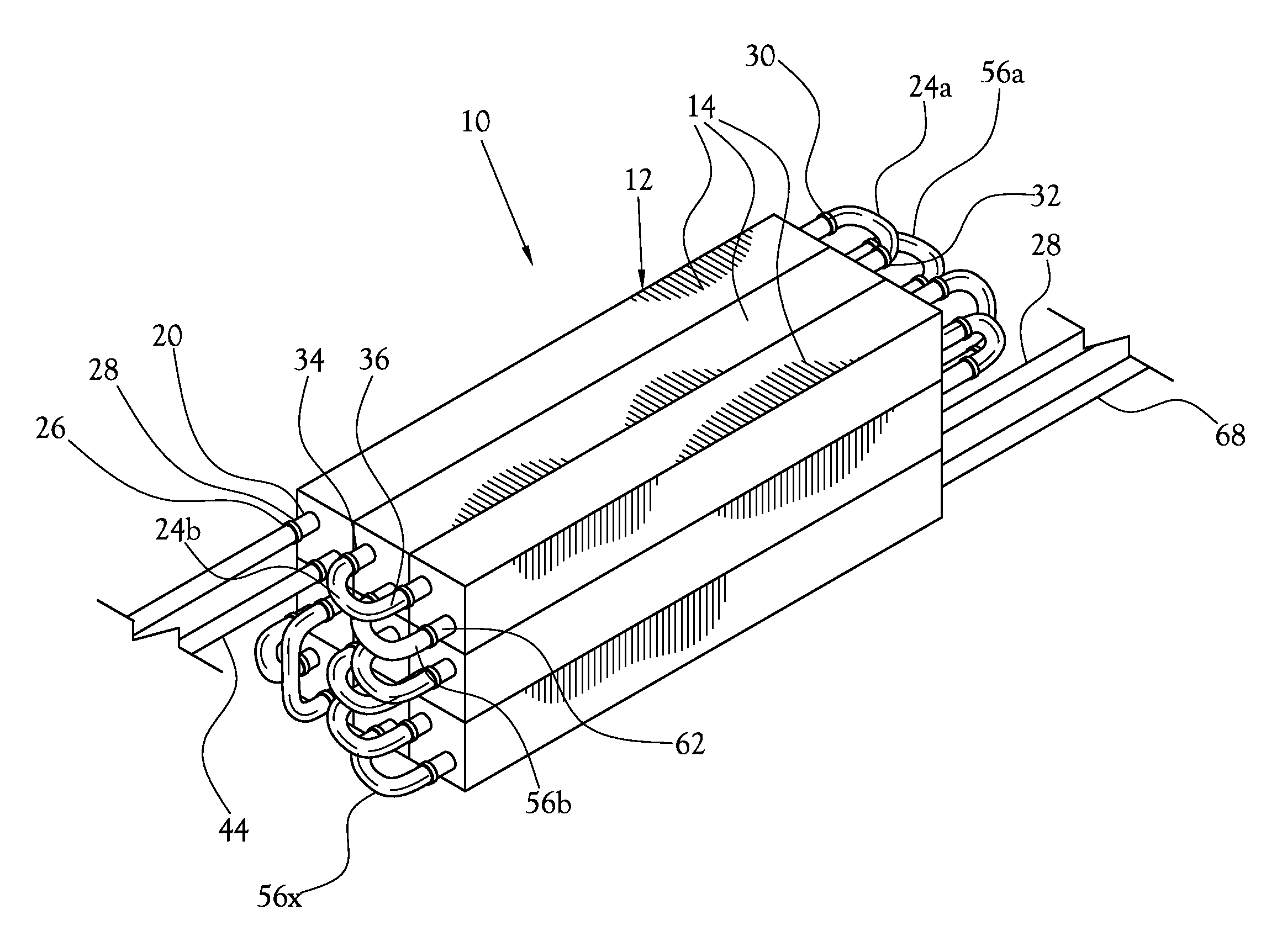

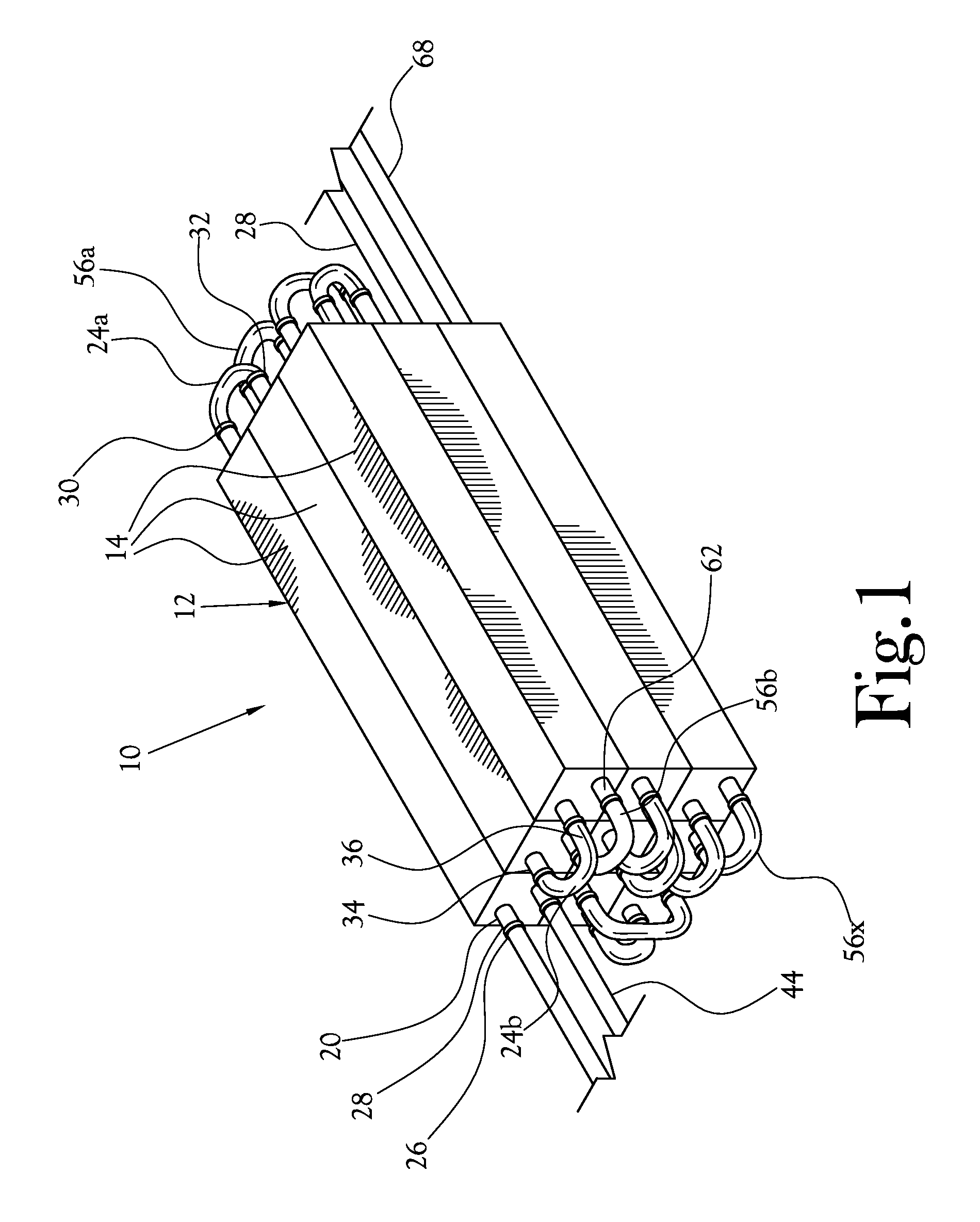

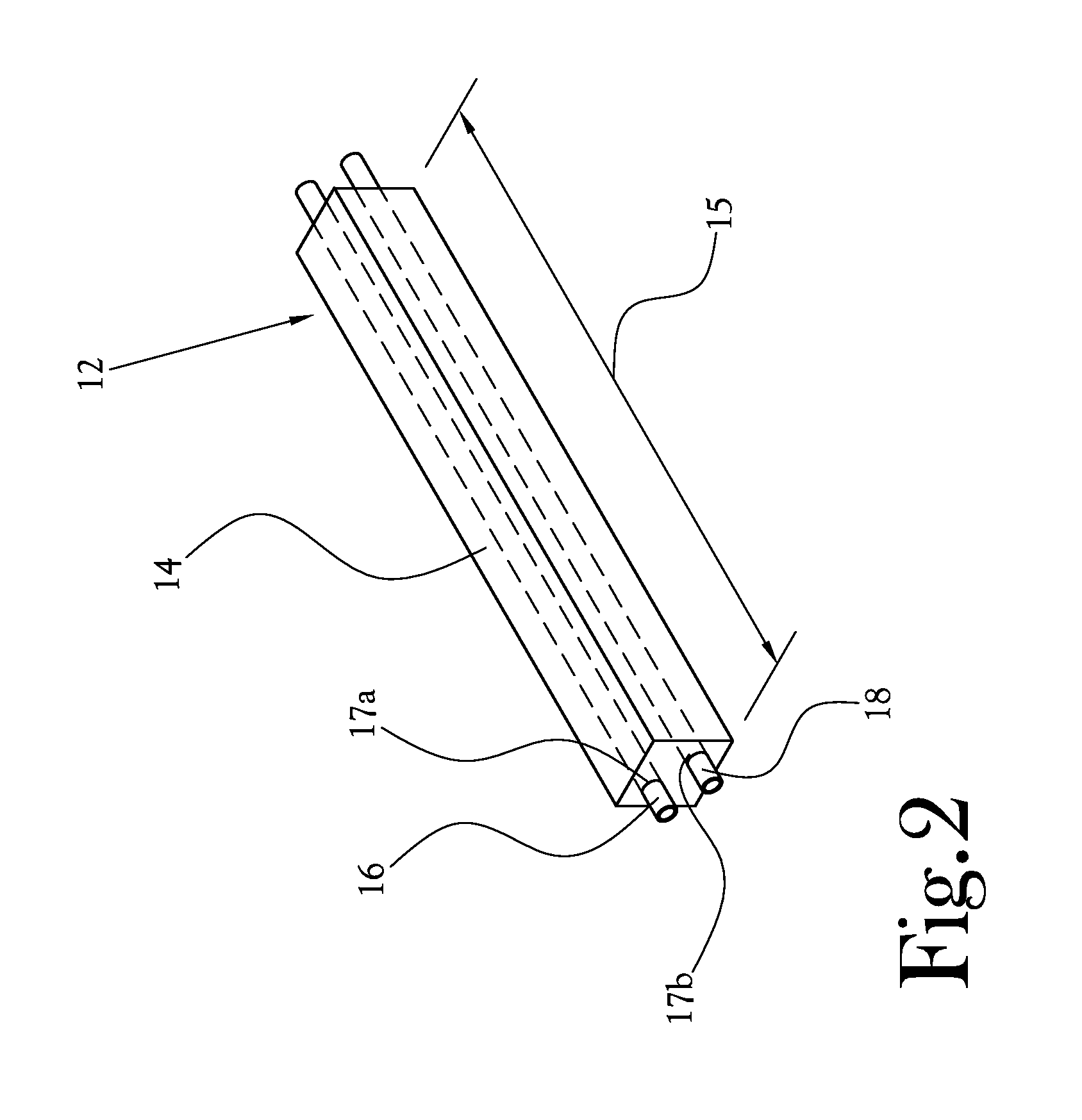

[0037]The present invention provides a modular thermal energy transfer system for collecting and / or supplying thermal energy during a first time frame, for retaining at least a portion of the thermal energy until a second time frame, and for transferring at least a portion of the thermal energy to a usable fluid during the second time frame. More specifically, the present invention provides a modular apparatus for transferring thermal energy between a first fluid and a medium, and / or supplying thermal energy and transferring the generated thermal energy to the medium, to create a temperature differential in the medium, maintaining the temperature differential in the medium, and applying the temperature differential to a second fluid to change the temperature in the second fluid.

[0038]A perspective view of one embodiment of the modular thermal energy transfer system constructed in accordance with the various features of the present invention is illustrated generally at 10 in FIG. 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com