Fan

a fan and fan body technology, applied in the field of portable fans, can solve the problems of inability to carry, time-consuming cleaning of bladed fans, etc., and achieve the effect of facilitating the connection of the filter uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

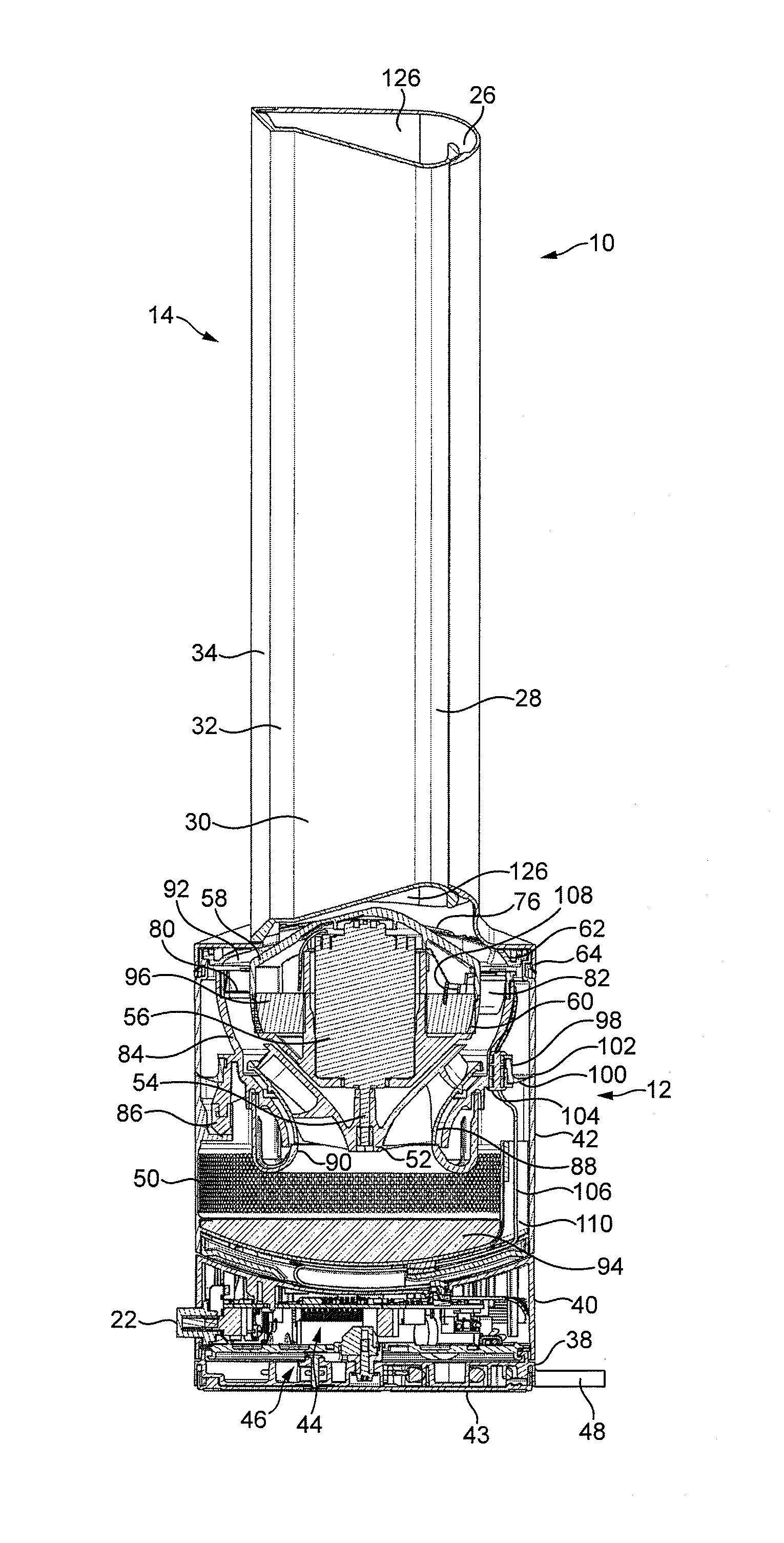

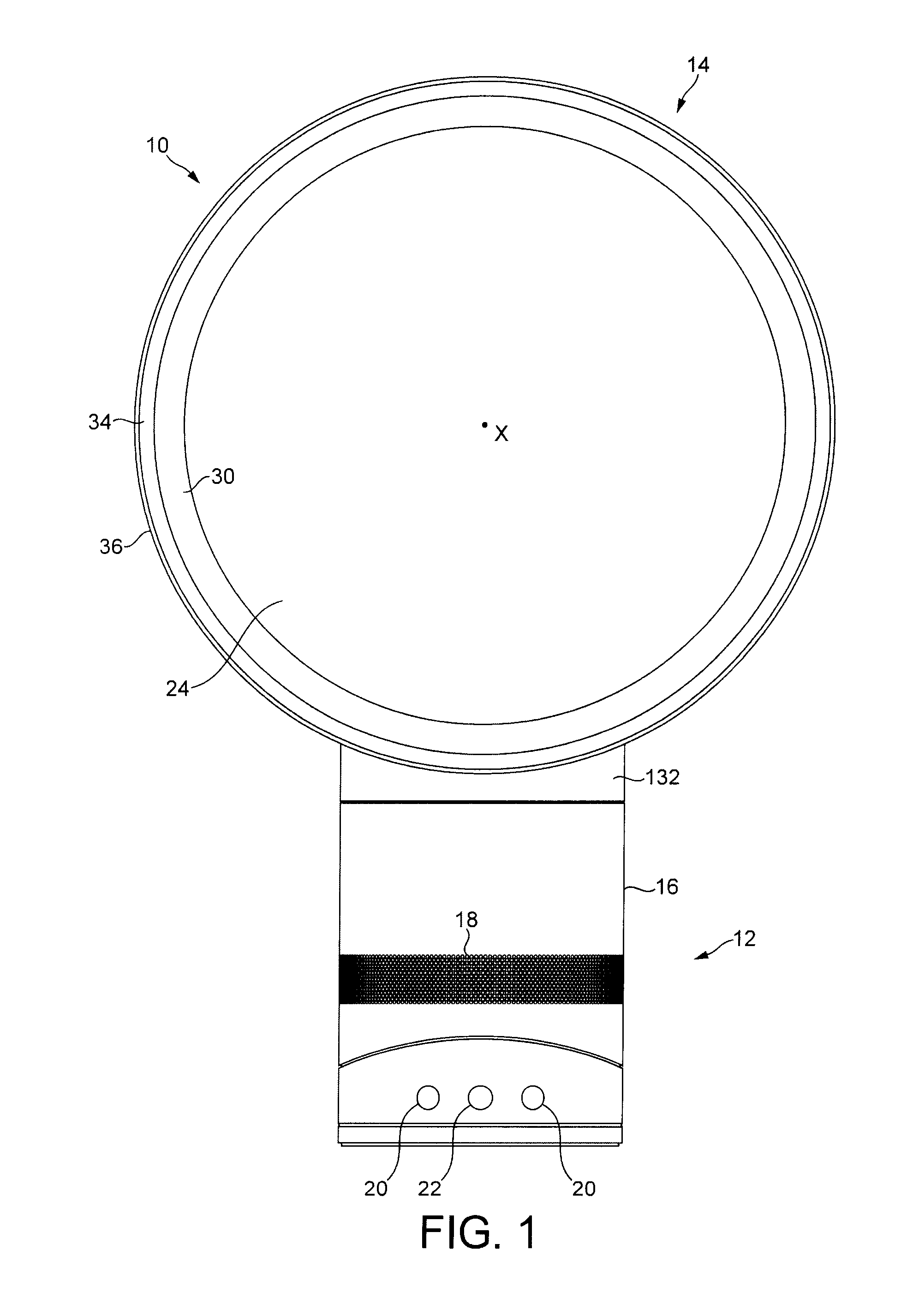

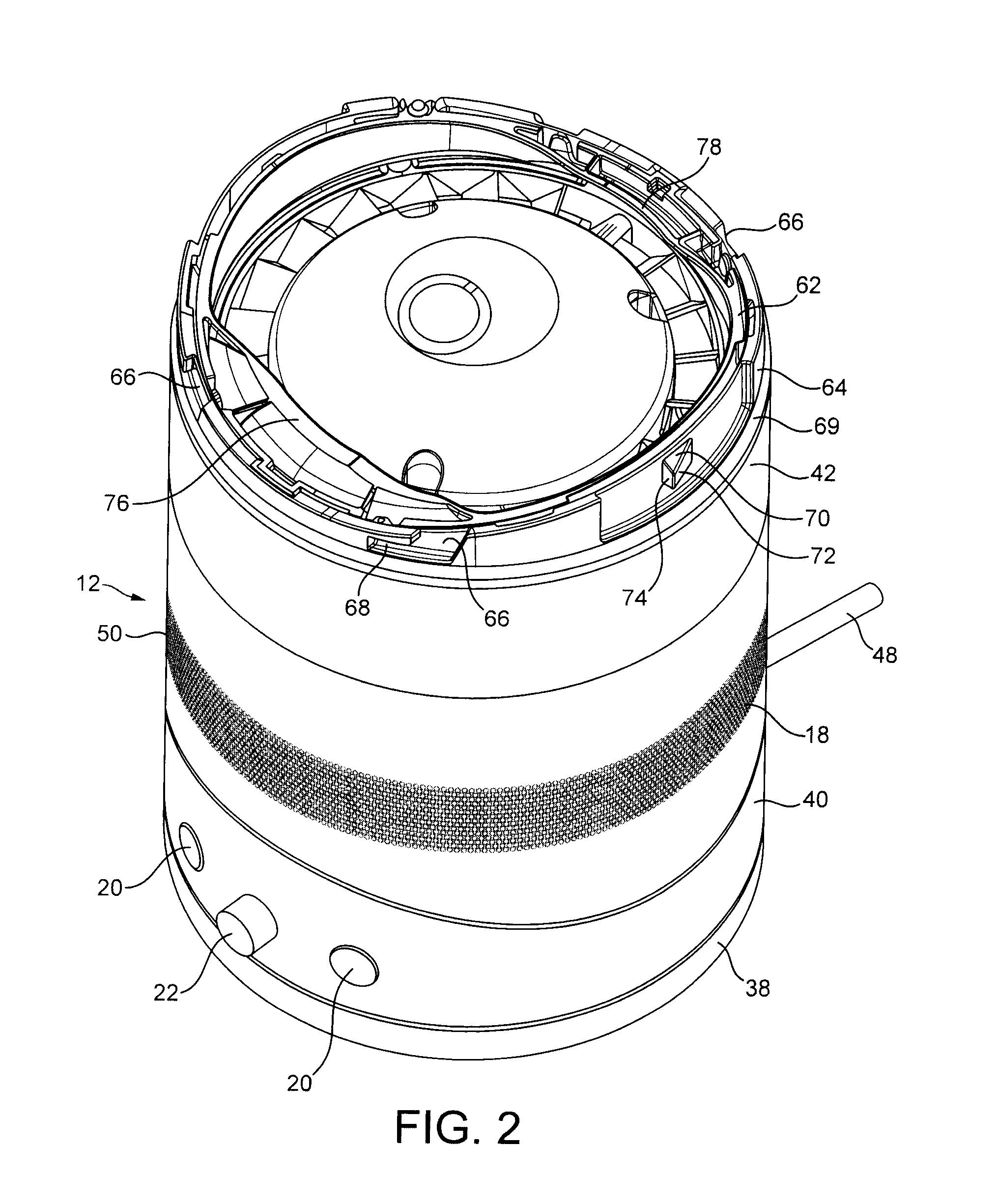

[0028]FIG. 1 is a front view of a fan 10. The fan 10 is preferably in the form of a bladeless fan 10 comprising a base 12 and an air outlet 14 connected to the base 12. With reference also to FIG. 2, the base 12 comprises a substantially cylindrical outer casing 16 having a plurality of air inlets 18 in the form of apertures formed in the outer casing 16 and through which a primary air flow is drawn into the base 12 from the external environment. The base 12 further comprises a plurality of user-operable buttons 20 and a user-operable dial 22 for controlling the operation of the fan 10. In this example the base 12 has a height in the range from 200 to 300 mm, and the outer casing 16 has an external diameter in the range from 100 to 200 mm.

[0029]As shown in FIG. 3, the air outlet 14 has an annular shape and defines an opening 24. The air outlet 14 has a height in the range from 200 to 400 mm. The air outlet 14 comprises a mouth 26 located towards the rear of the fan 10 for emitting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com