Aircraft tire and method of manufacture

a technology of pneumatic tires and airframes, applied in the field of pneumatic tires, can solve the problems of high degree of flexure in the crown area of pneumatic tires for high-speed applications, tire designs with zigzag belt layers cannot carry as heavy a load as required by current commercial aircraft design requirements,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

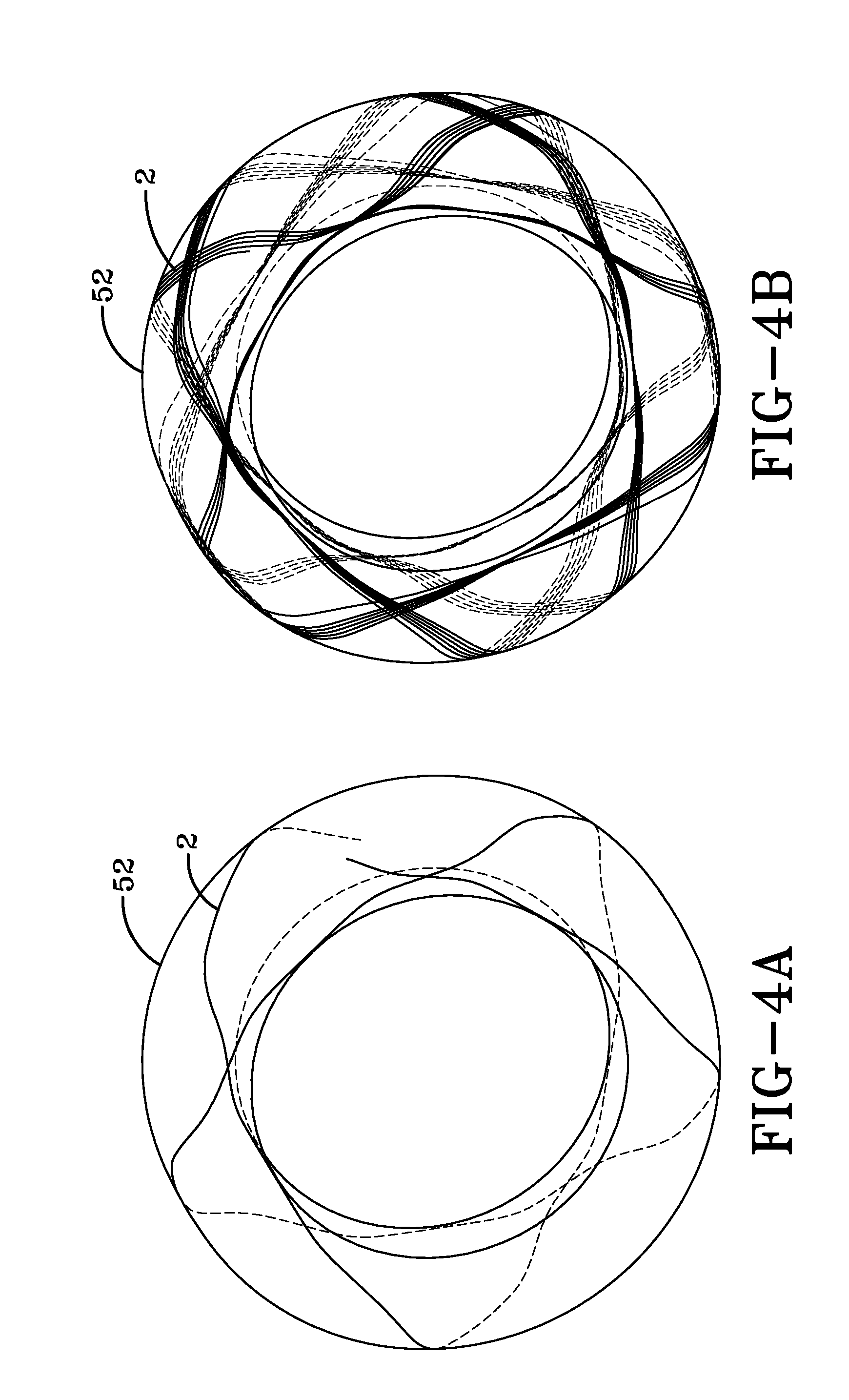

[0041]FIGS. 6-9 illustrate a green tire carcass of the present invention. The cords of the carcass are arranged in a geodesic orbital pattern wherein the cords are tangent to the bead radius of the tire. The close proximity of the cords results in a very large buildup of cord material in the bead area. In order to overcome this inherent disadvantage, the inventors modified the ply layup as described in more detail, below.

Apparatus

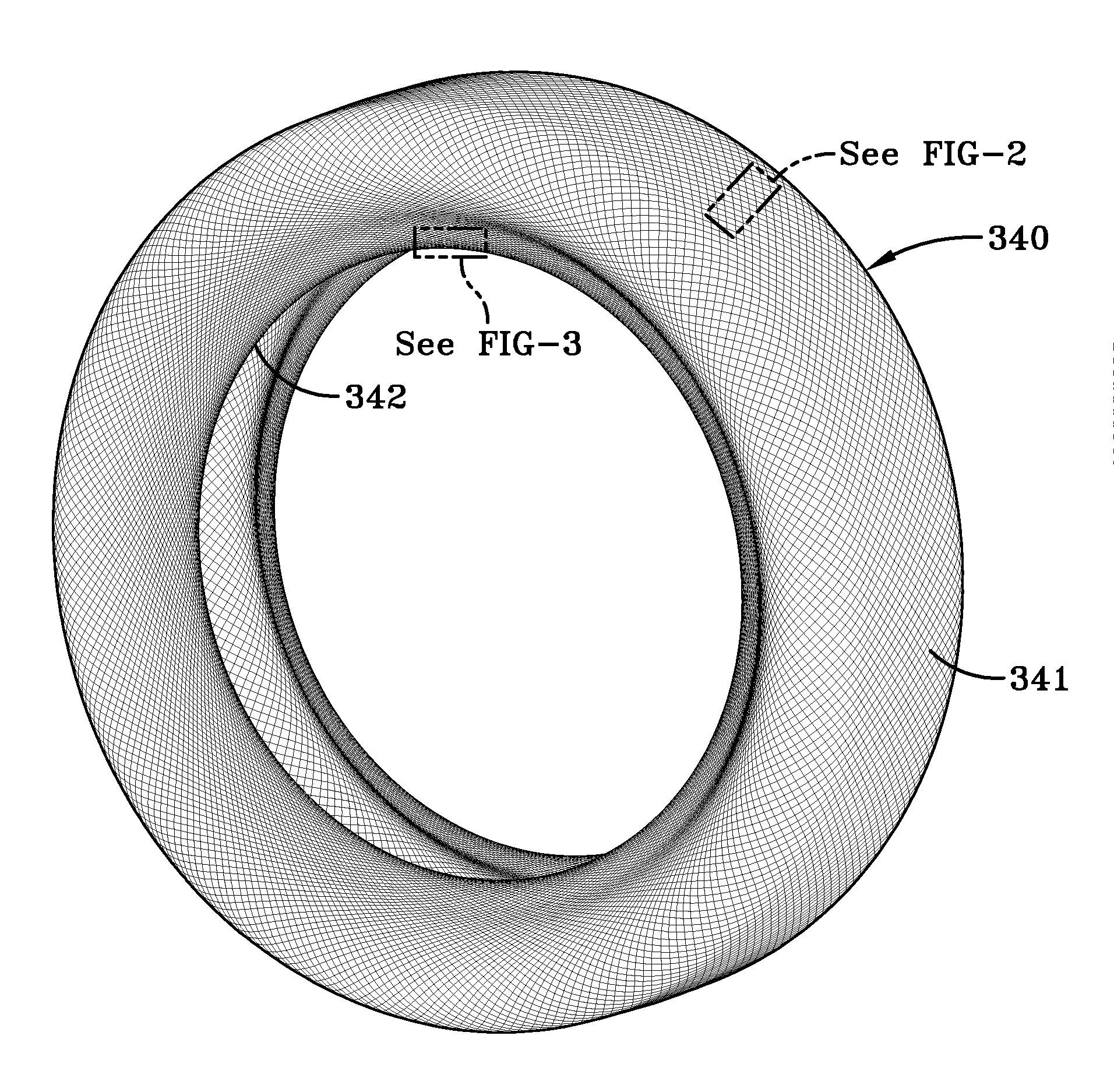

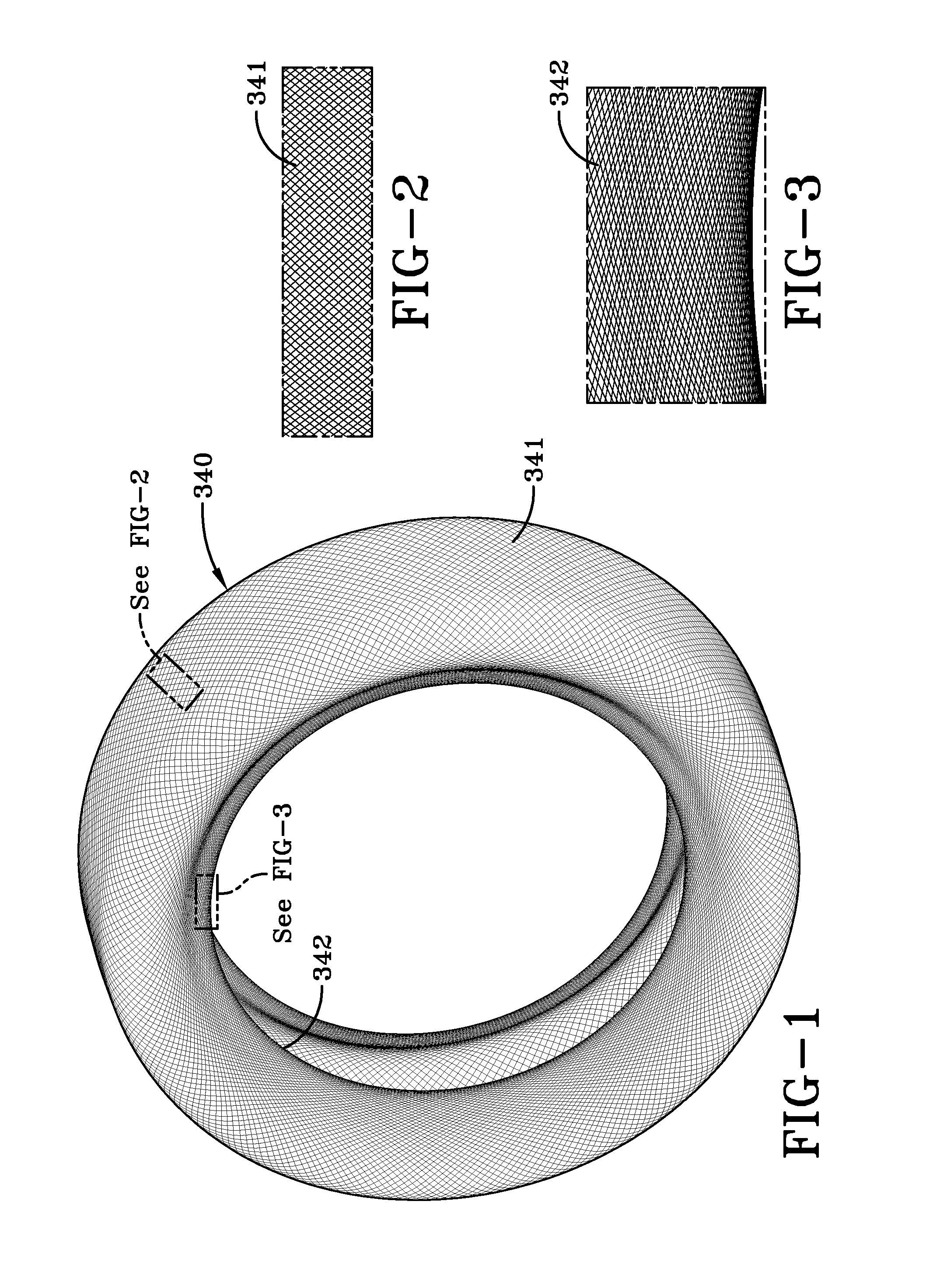

[0042]In a first embodiment of the invention, the tire 300 having a geodesic carcass is formed on a torus shaped core or tire blank 52. The core has an outer core surface which may be in the shape of a cylinder such as a tire building drum, a buffed carcass for a tire to be retreaded, and is preferably torus shaped to closely match the interior shape of the tire. The core is rotatably mounted about its axis of rotation and is shown in FIGS. 10 and 11. The core may be collapsible or formed in sections for ease of removal from the tire. The core may also cont...

second embodiment

[0049]an apparatus suitable for applying ply in a geodesic pattern onto a core is shown in FIG. 12. The apparatus includes a ply applier head 200 which is rotatably mounted about a Y axis. The ply applier head 200 can rotate about the Y axis + / −100 degrees. The rotation of the ply applier head 200 is necessary to apply the cord in the shoulder and bead area. The ply applier head 200 can thus rotate about rotatable core 52 on each side in order to place the ply in the sidewall and bead area. The ply applier head 200 is mounted to a support frame assembly which can translate in the X, Y and Z axis. The ply applier head has an outlet 202 for applying one or more cords 2. The cords may be in a strip form and comprise one or more rubber coated cords. Located adjacent the ply applier head 200 is a roller 210 which is pivotally mounted about an X axis so that the roller can freely swivel to follow the cord trajectory. The ply applier head and stitcher mechanism are precisely controlled by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com