Optical connector, and assembling method of optical connector

a technology of optical connectors and connectors, applied in the field of optical connectors, can solve the problems of cumbersome work such as the attachment of the boot and the protecting tube, troublesome fiber breakage, and take some time, and achieve the effect of reducing the number of connections and parts, and facilitating and stably assembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

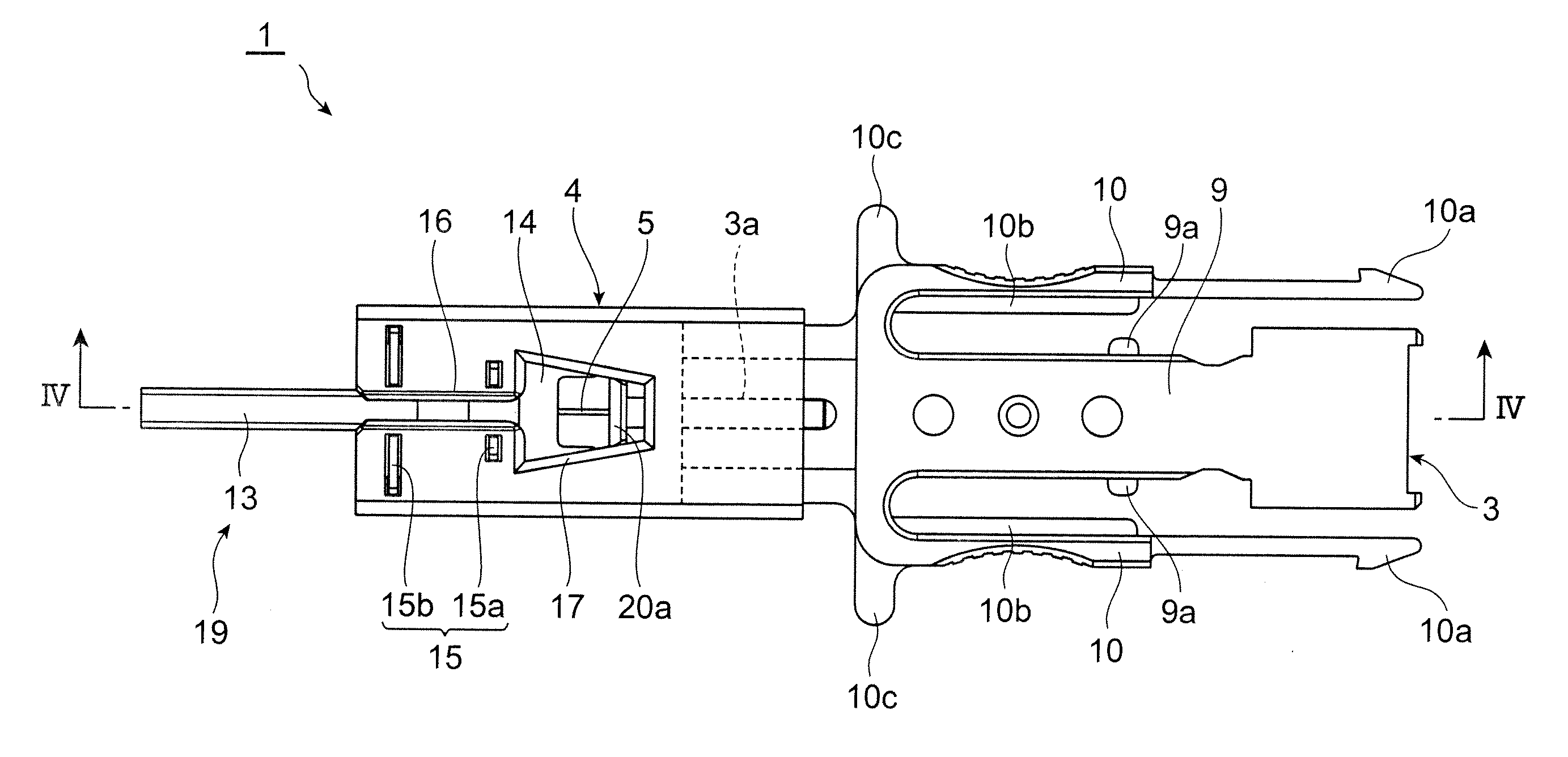

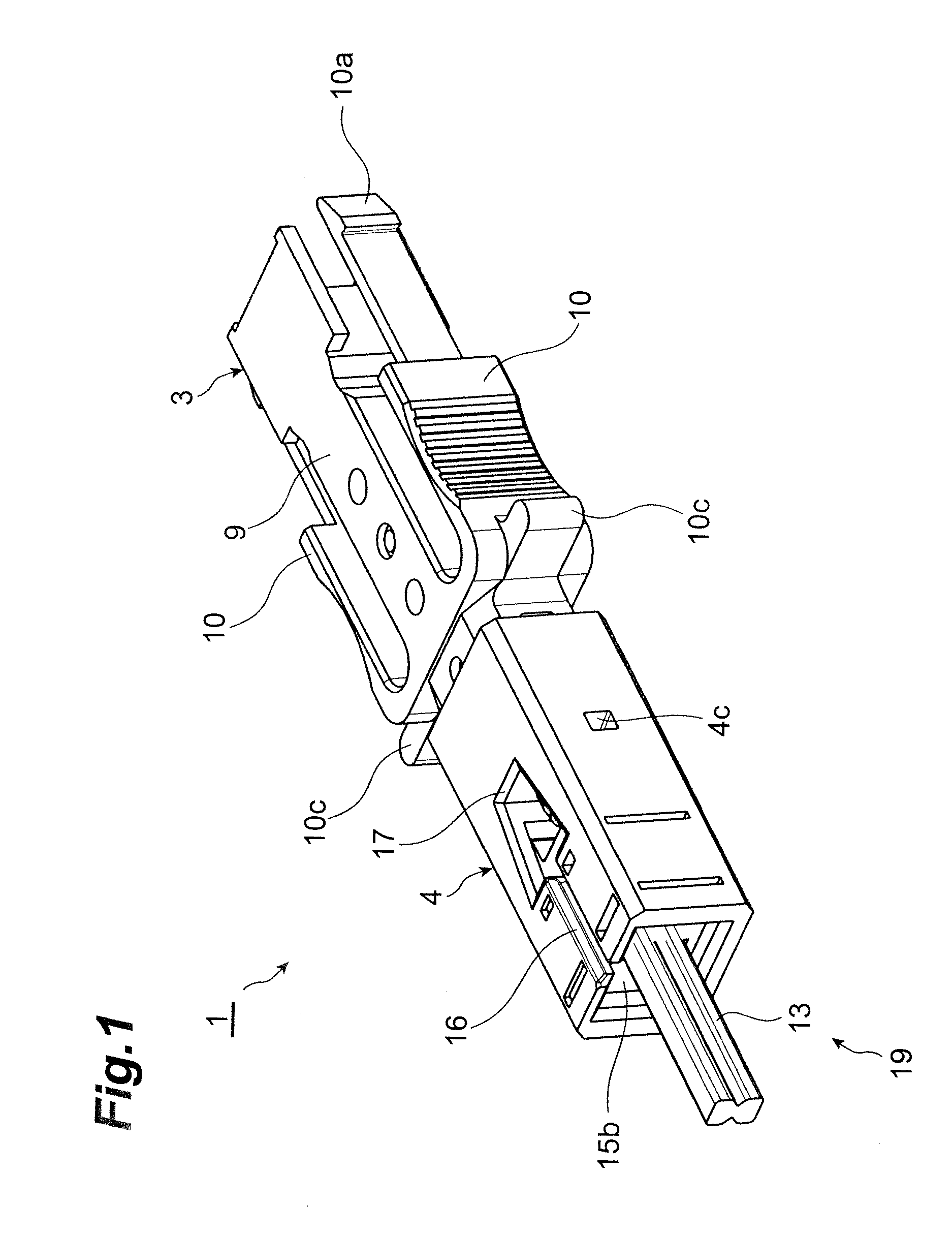

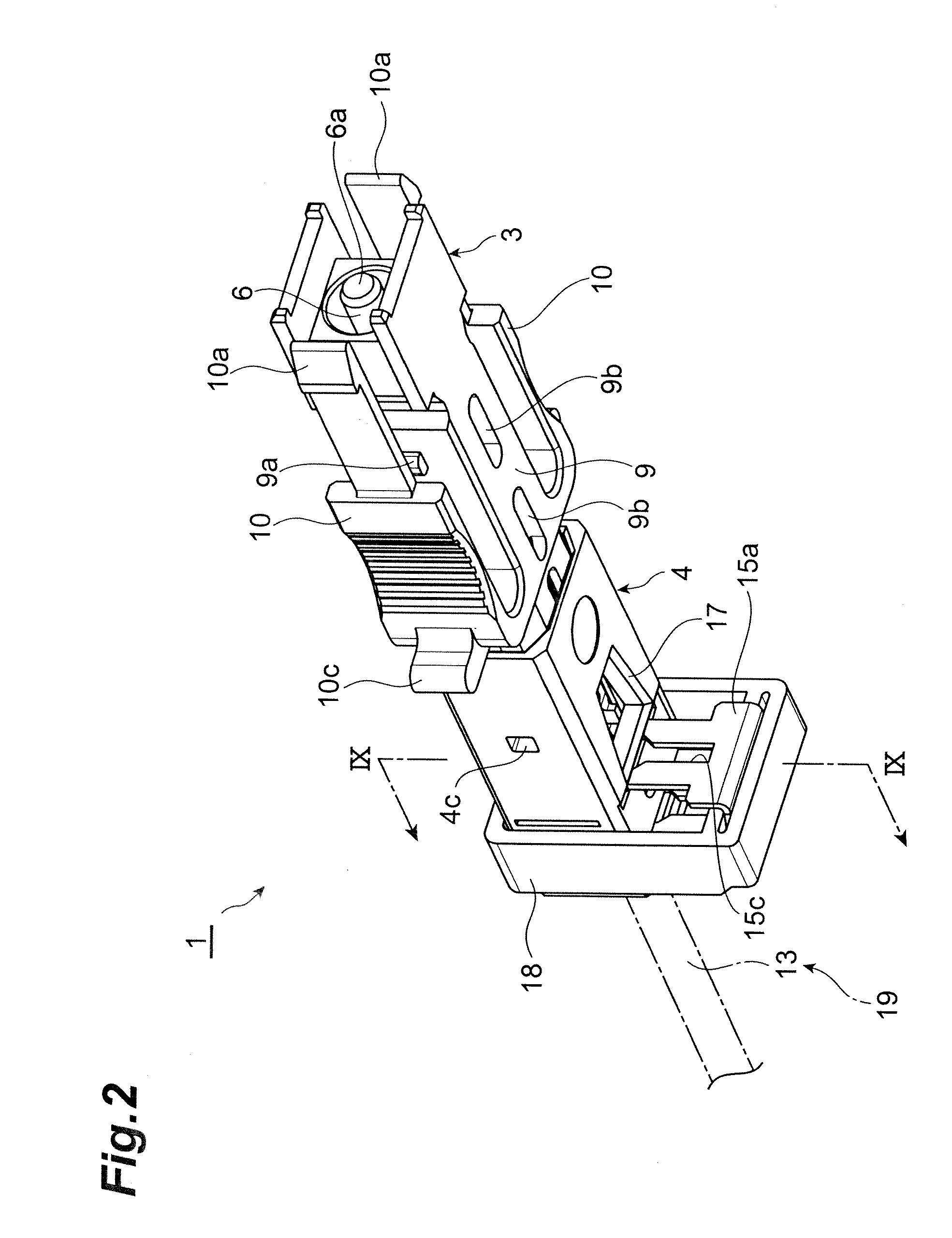

[0080]FIG. 1 is a perspective view of a male optical connector according to the first embodiment of the present invention, FIG. 2 a perspective view of the lower side of the male optical connector (before insertion of a clip) shown in FIG. 1, FIGS. 3 to 5 views showing the male optical connector, FIG. 6 a perspective view of a coupling member shown in FIG. 5, FIG. 7 a perspective view of a spring push shown in FIG. 5, FIGS. 8 and 9 views showing a jacket holder shown in FIG. 5, and FIG. 18 a transverse sectional view of an indoor cable. In the description hereinafter, terms indicating directions will be based on the state shown in FIG. 1. Specifically, a direction in which a jacket fixture is located relative to an outer housing is defined as “back.”

[0081]The optical connector of the present embodiment is an in-situ assembling type single-fiber optical connector having a mechanical splice structure and being suitable for assembly at a job site, and is used for connection of an optic...

second embodiment

[0159]Next, a male optical connector according to the second embodiment of the present invention will be described with reference to FIGS. 19 to 23. FIG. 19 is a perspective view of the male optical connector in a closed lid state (before attachment of an optical cable), and FIGS. 20 to 23 are views showing the male optical connector of FIG. 19 in an open lid state. This male optical connector 31 of the second embodiment is different from the male optical connector 1 of the first embodiment in that the jacket fixture 4 shown in FIG. 1 is replaced by a jacket fixture 32 shown in FIGS. 19-23 and in that the jacket holder 14 shown in FIG. 5 is replaced with a jacket holder 37 shown in FIG. 21, without the clip 15 shown in FIG. 5.

[0160]Specifically, as shown in FIGS. 19-23, the jacket fixture 32 is provided with a jacket fixture body 33 coupled to the mechanical splice through a coupling member having much the same function as in the first embodiment, a first movable portion 35 and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com