Complete prefabricated mechanical & utility system

a prefabricated system and complete technology, applied in the field of prefabricated systems, can solve the problems of inefficiency, waste of time of skilled labor, materials and future resources, and expenditure of the overall cost of any project, and the cost of skilled labor is not high, and the efficiency of the job site is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

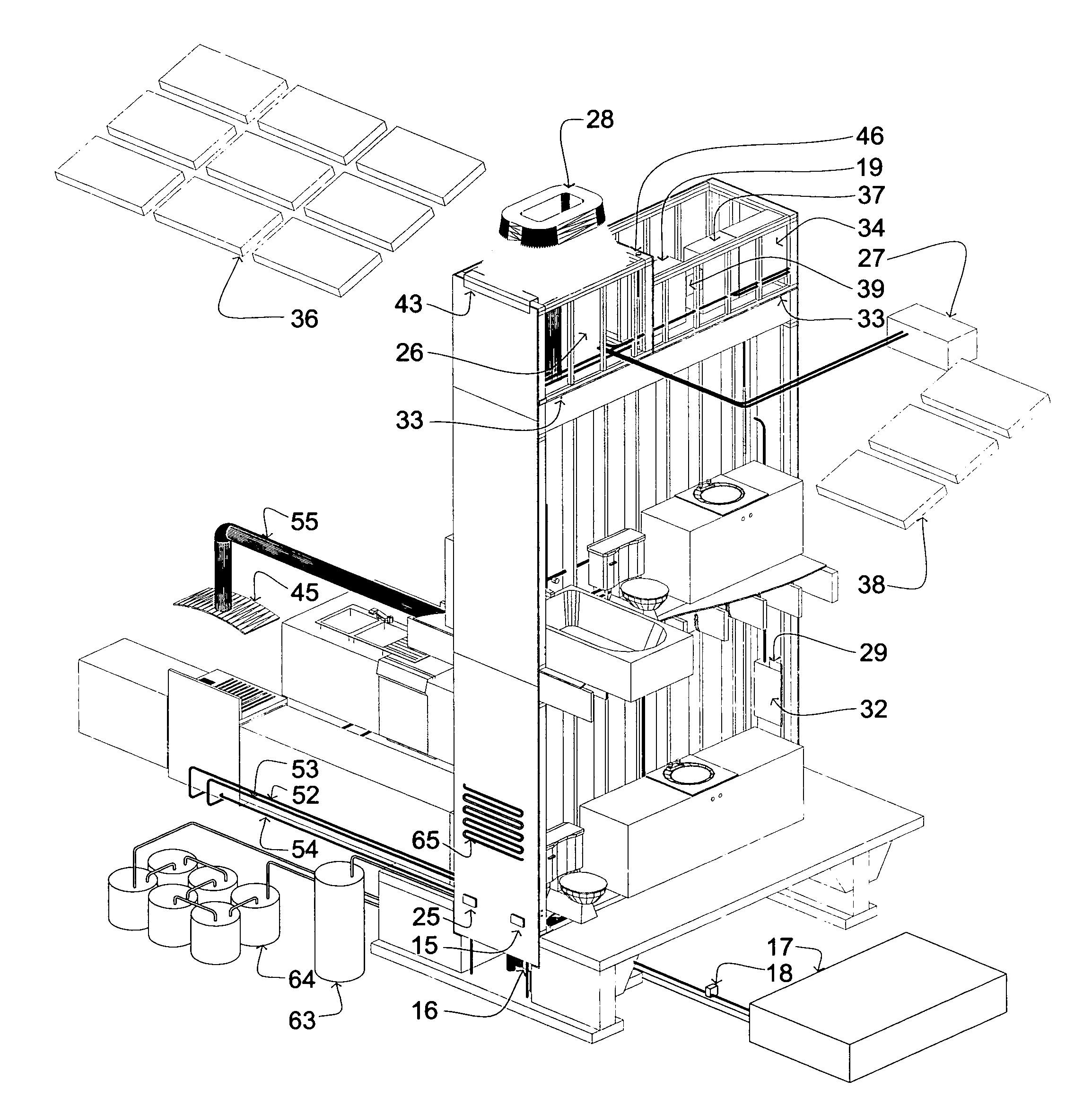

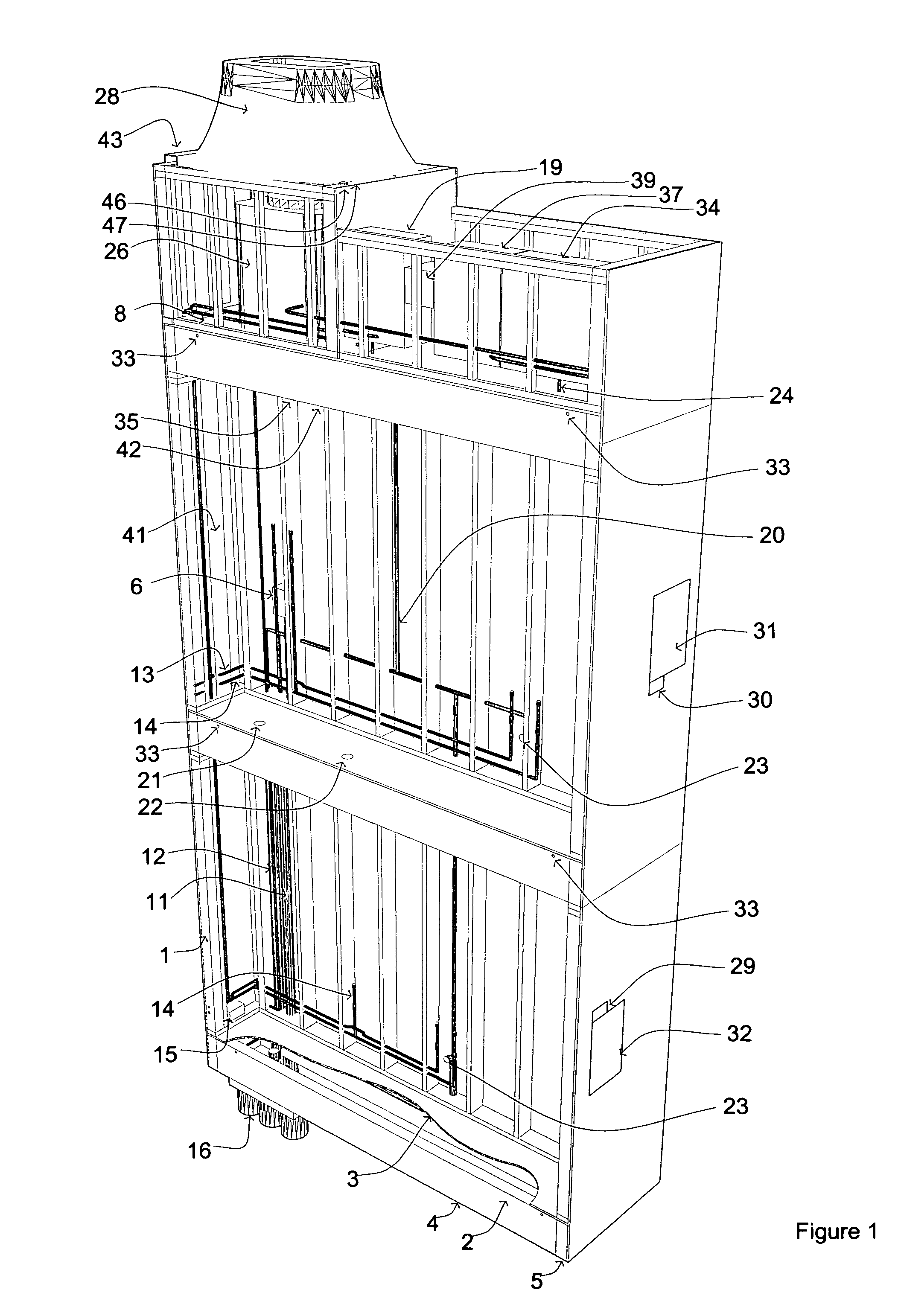

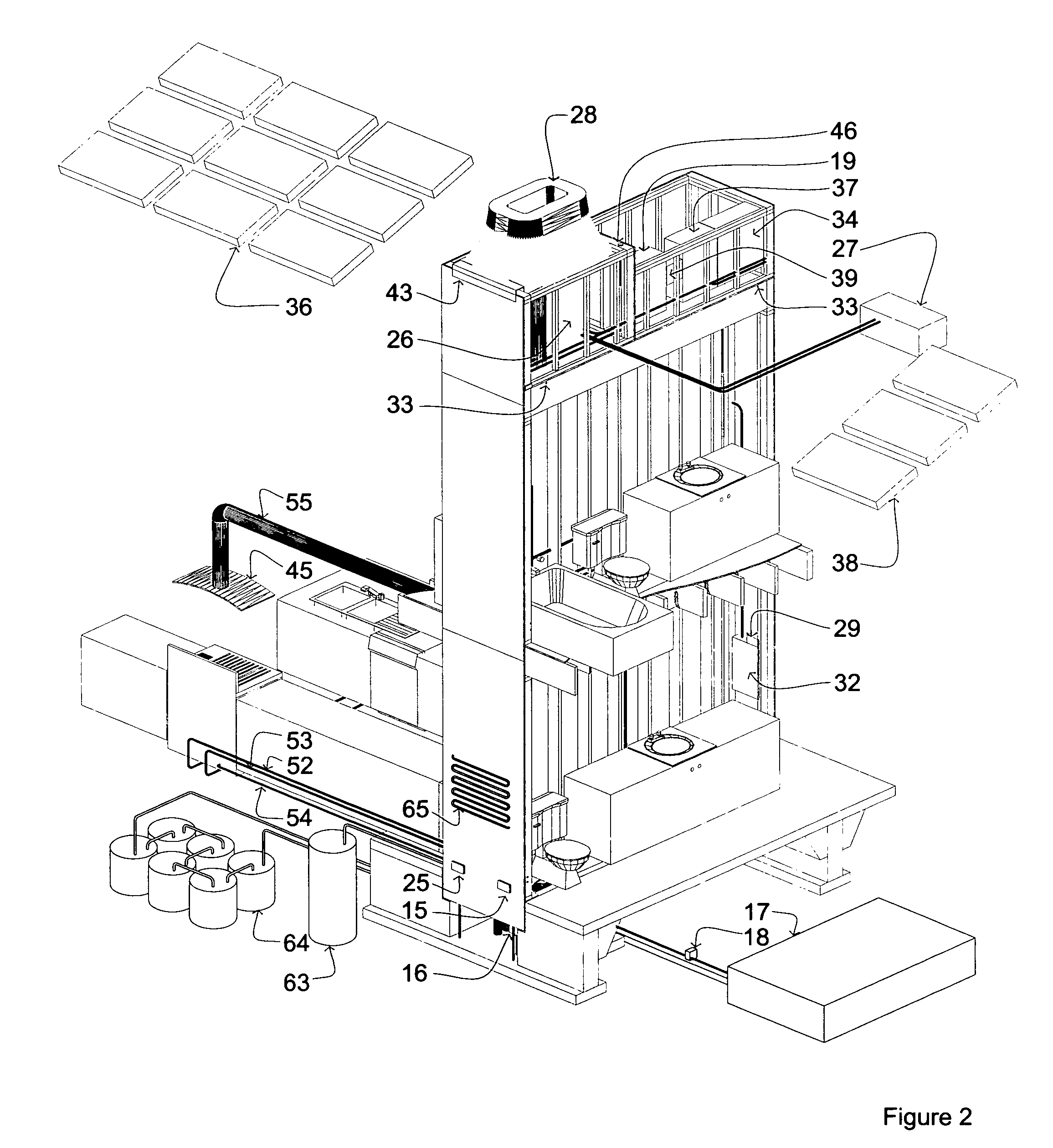

[0037]Embodiments of the invention can be used in the construction of buildings to reduce cost, improve efficiency, reduce construction time, and decrease a buildings operational costs. The unit is prefabricated at a factory and is of a transportable size. The unit is transported to a site that is prepared for the installation of the unit. The unit would preferably be fabricated in an assembly line method.

[0038]The prepared site would preferably have foundation and all utility inlets in place. A premade form is used to cast the foundation and with ensure proper placement of utility inlets while reducing the cost and waste of additional formwork when pouring the foundation.

[0039]The invention is a part or whole of the mechanical and utility systems for a building. Once installed and inlets have been attached the system is able to operate. Additional elements may be added at the site so that the unit can be customized to any situation. The ability to be customized makes the system ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com