Transportable bulk container with slide gate dispenser

a technology of gate dispenser and bulk container, which is applied in the field of containers, can solve problems such as the movement of gate plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

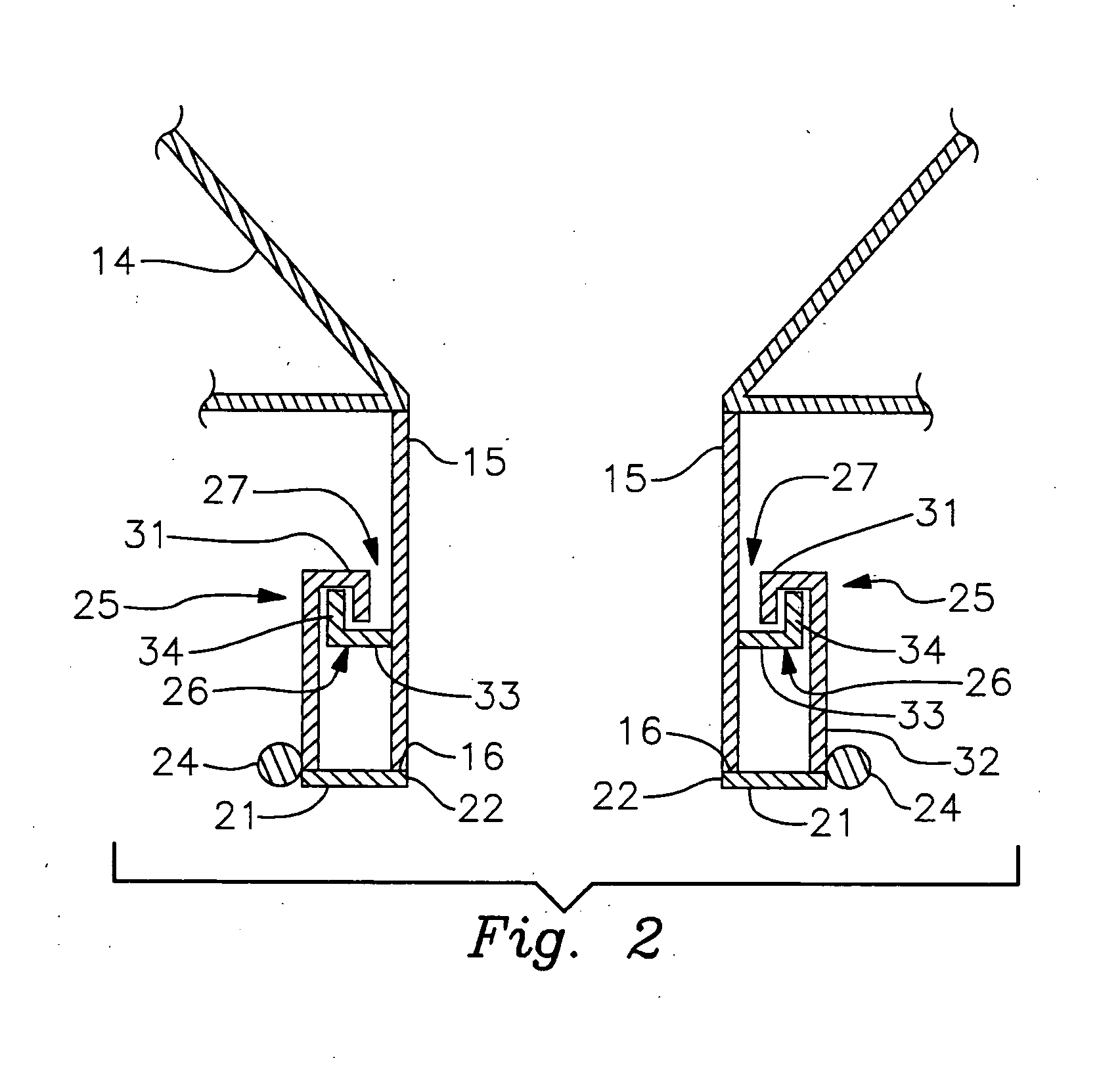

[0010]With reference to the drawings, the invention will now be described in detail with regard for the best mode and preferred embodiment. In general, the invention is a transportable bulk container having a slide gate mechanism for release of the bulk material from the bottom of the hopper, the bulk container being structured so that it can be lifted and moved by a forklift, hand truck or similar device.

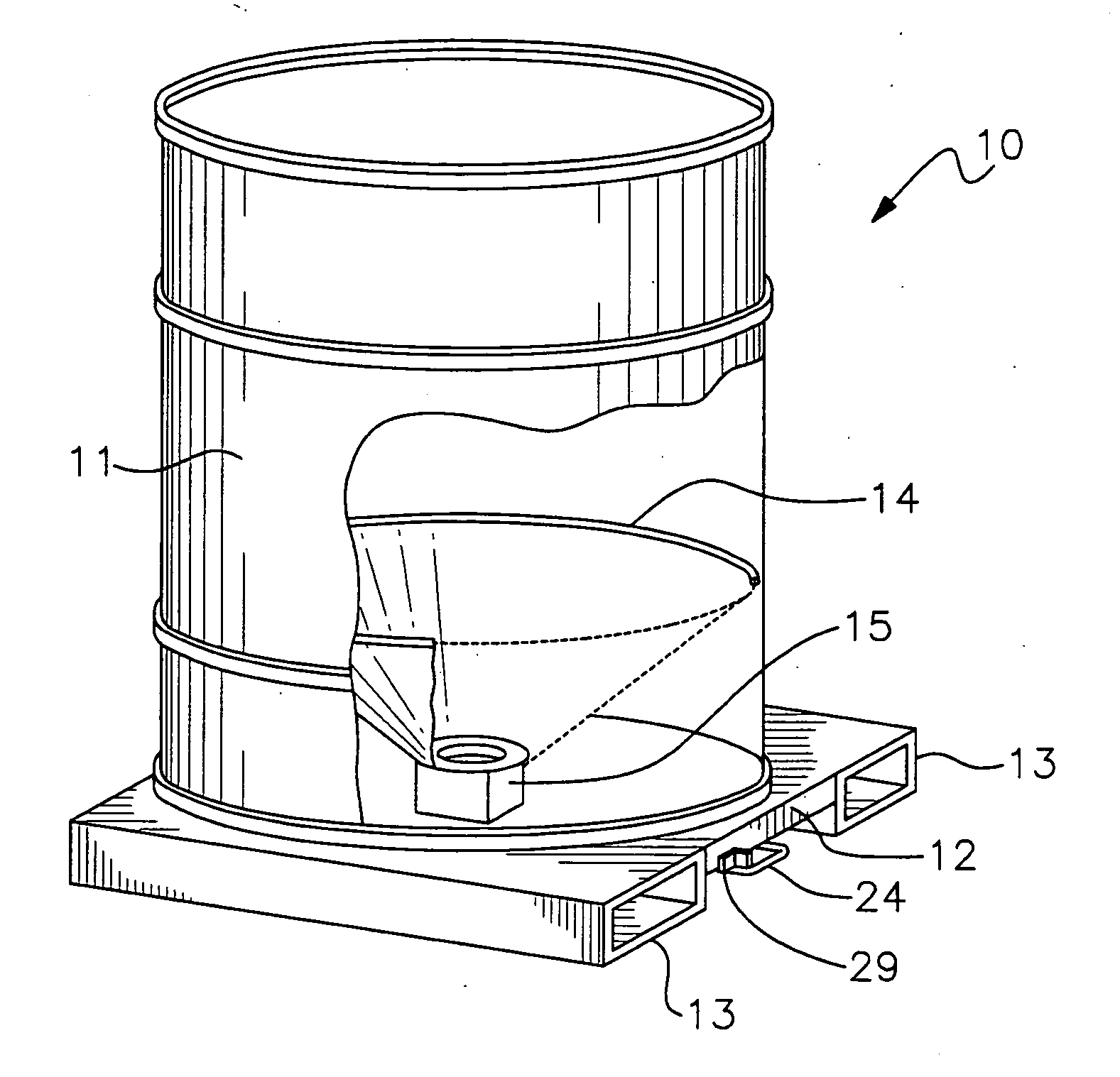

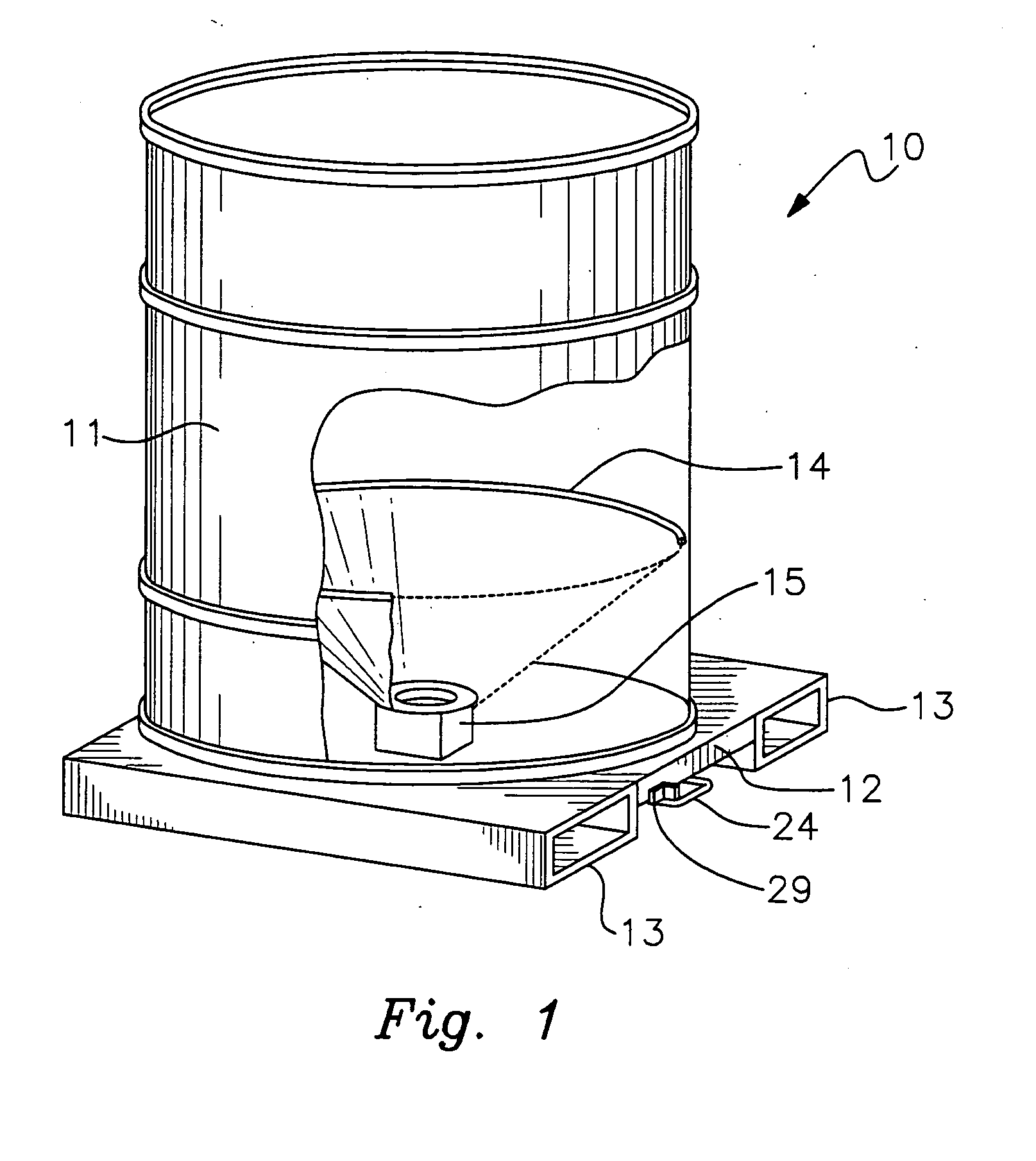

[0011]A representative embodiment of the transportable bulk container 10 is shown in FIG. 1, wherein the bulk container 10 comprises a relatively large hopper, bin or like receptacle member 11, shown here in the shape of a barrel or drum, although other shapes such as for example rectangular may be utilized. The hopper 11 is mounted onto a pallet or pallet-like member 12, the pallet member 12 comprising a pair of tine-receiving members 13 to receive the tines of a forklift, hand truck or the like, thereby enabling movement of the heavy bulk container 10. Preferably, the hopper 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com