System and Method for Skirting a Manufactured Home

a manufactured home and system technology, applied in the field of manufactured home skirting, can solve the problems of prior art system, leakage path around the attachment hole in the exterior wall, damage to the exterior wall of the home,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

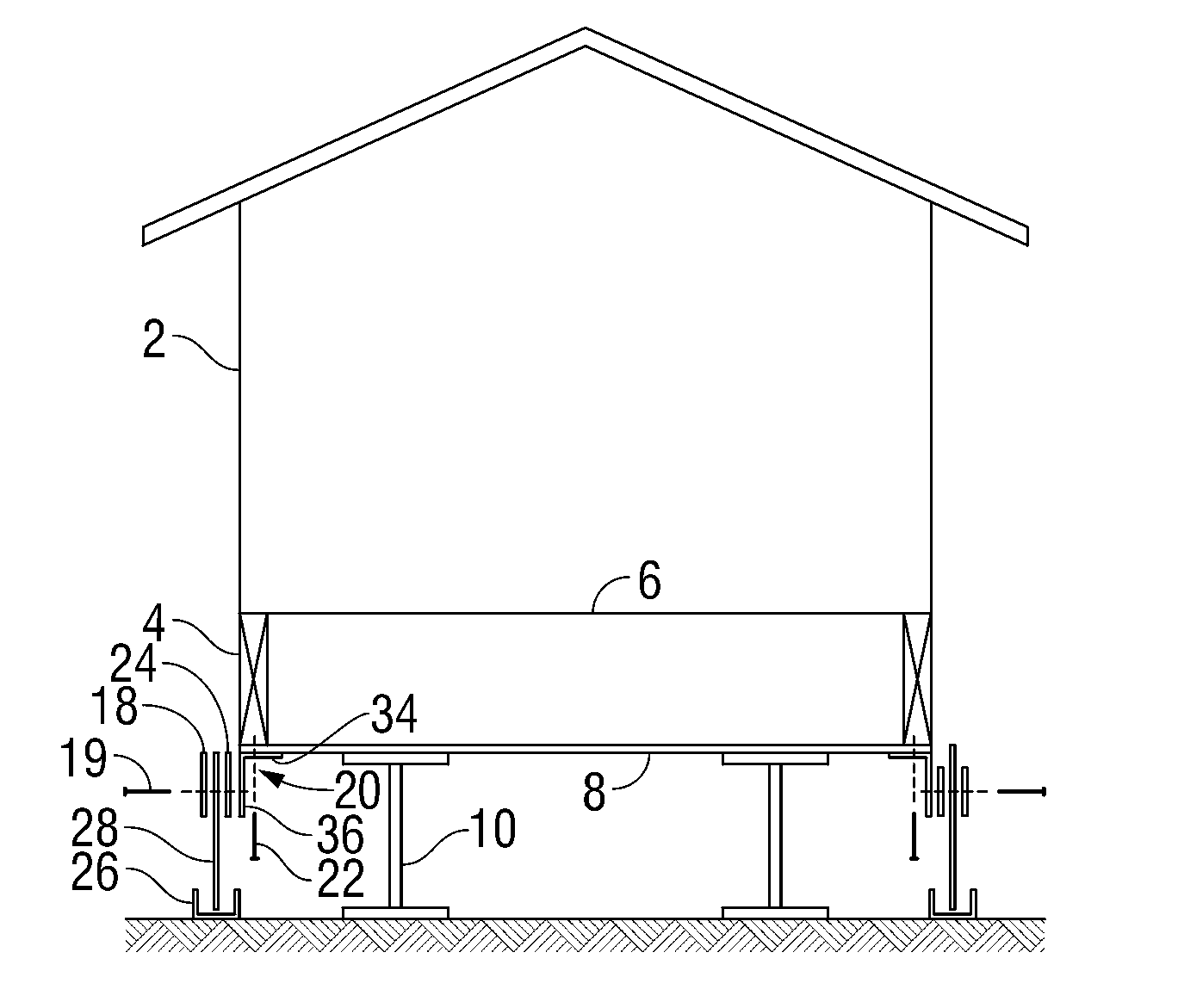

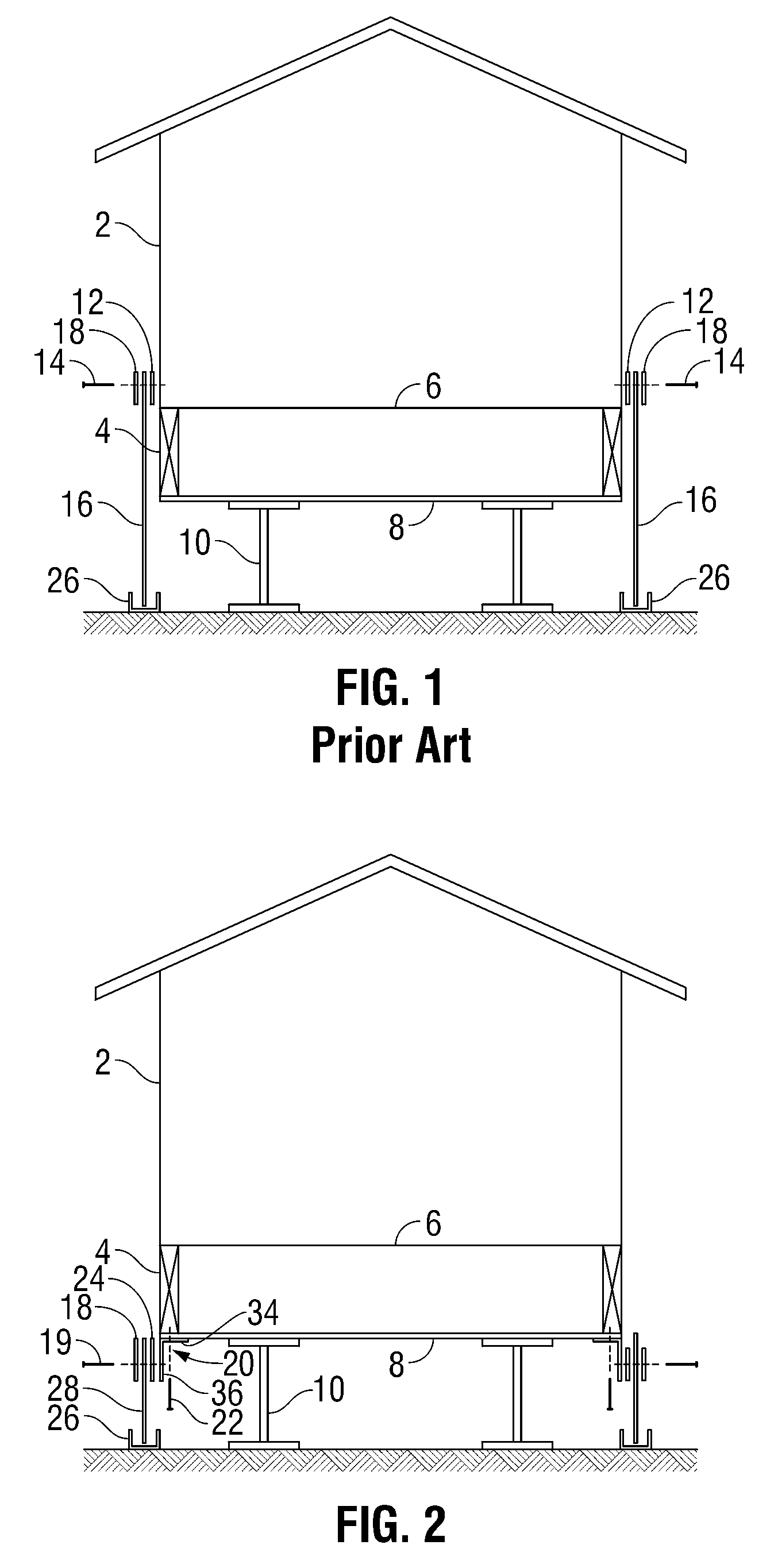

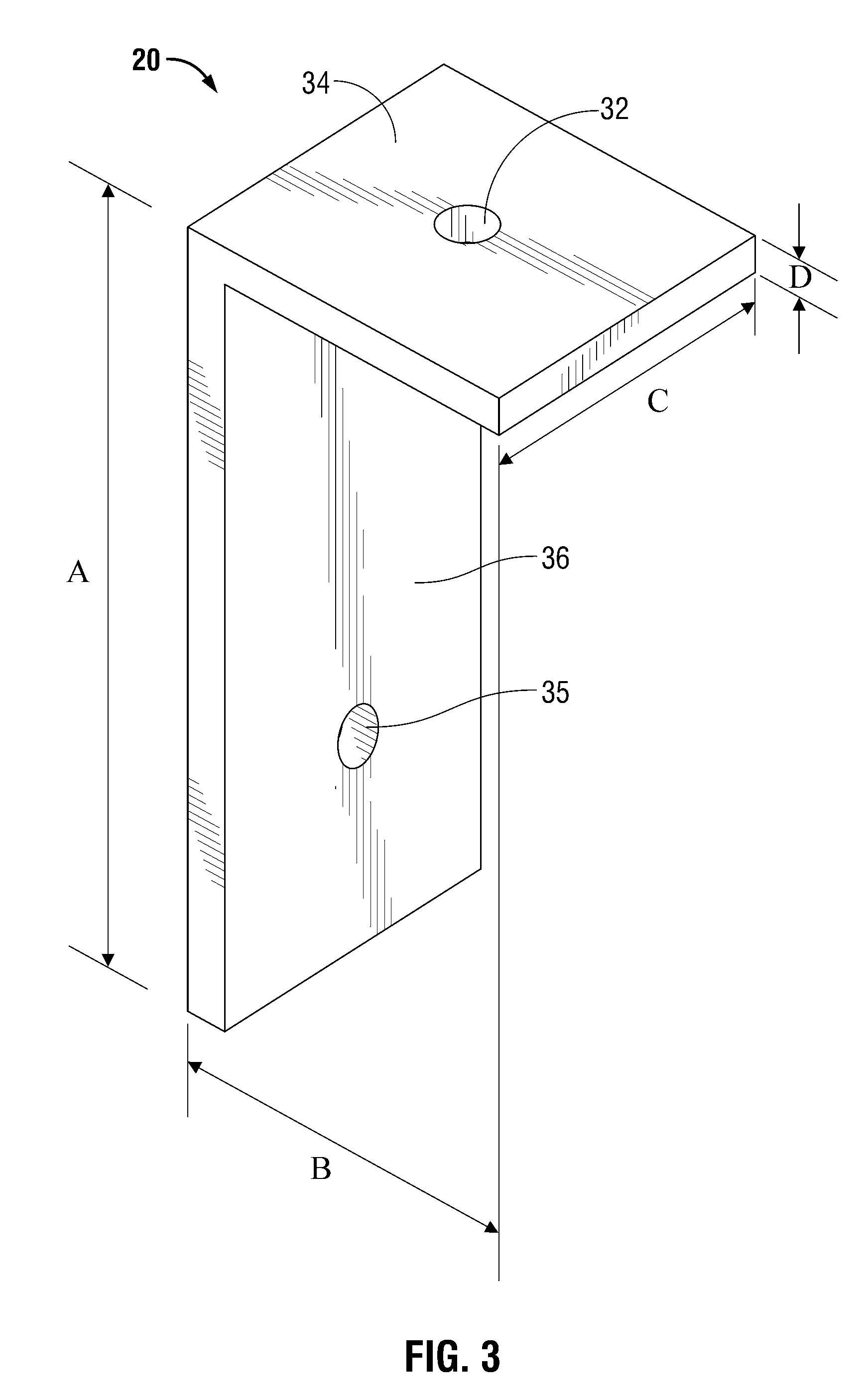

[0018]FIG. 1 shows a manufactured home 2 positioned on a wood frame flooring system comprising perimeter beams or outer rim joists 4 and inner beams or joists 6. Moisture barrier 8 is sandwiched or inserted between the wood flooring system and the steel frame system, comprising I-beams 10. The I-beams 10 are positioned on the ground. The top back skirting rail 12 is attached with screws 14 to the exterior wall of home 2. Screws 14 may be positioned at uniform locations, such as 16 inches on center, around the perimeter of the home 2 above the floor. The top of the skirting panel 16 is sandwiched or inserted between the top back skirting rail 12 and the top front skirting rail 18. Although the skirting is typically made of vinyl materials, other skirting panels can be used with this novel system and method, including natural (wood), metal and synthetic materials. The skirting rails (12, 18) snap together to hold the skirting panel 16. The skirting rails are typically 4 to 6 inches hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com