Multi-event telescopic platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

I. Overview

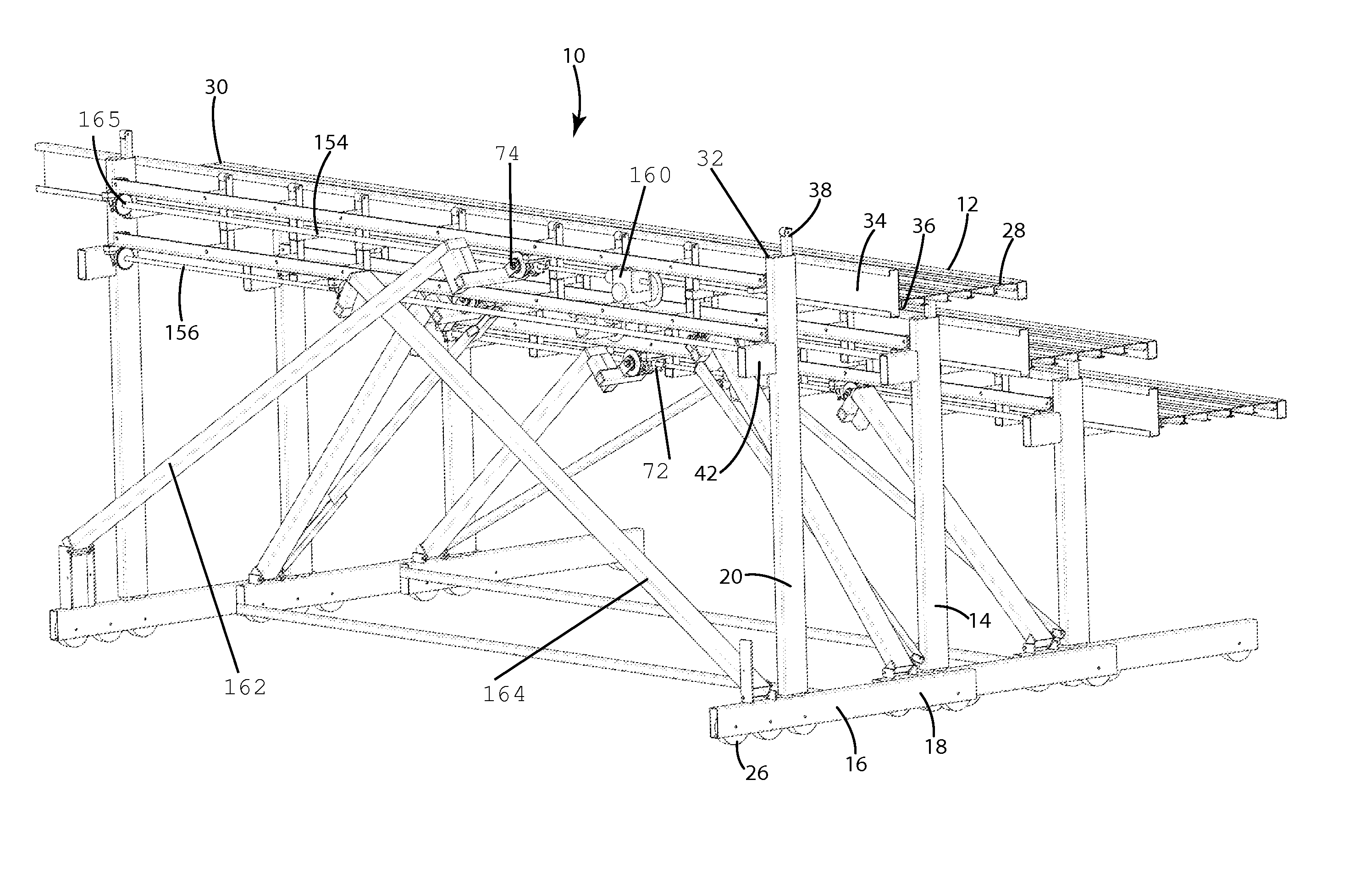

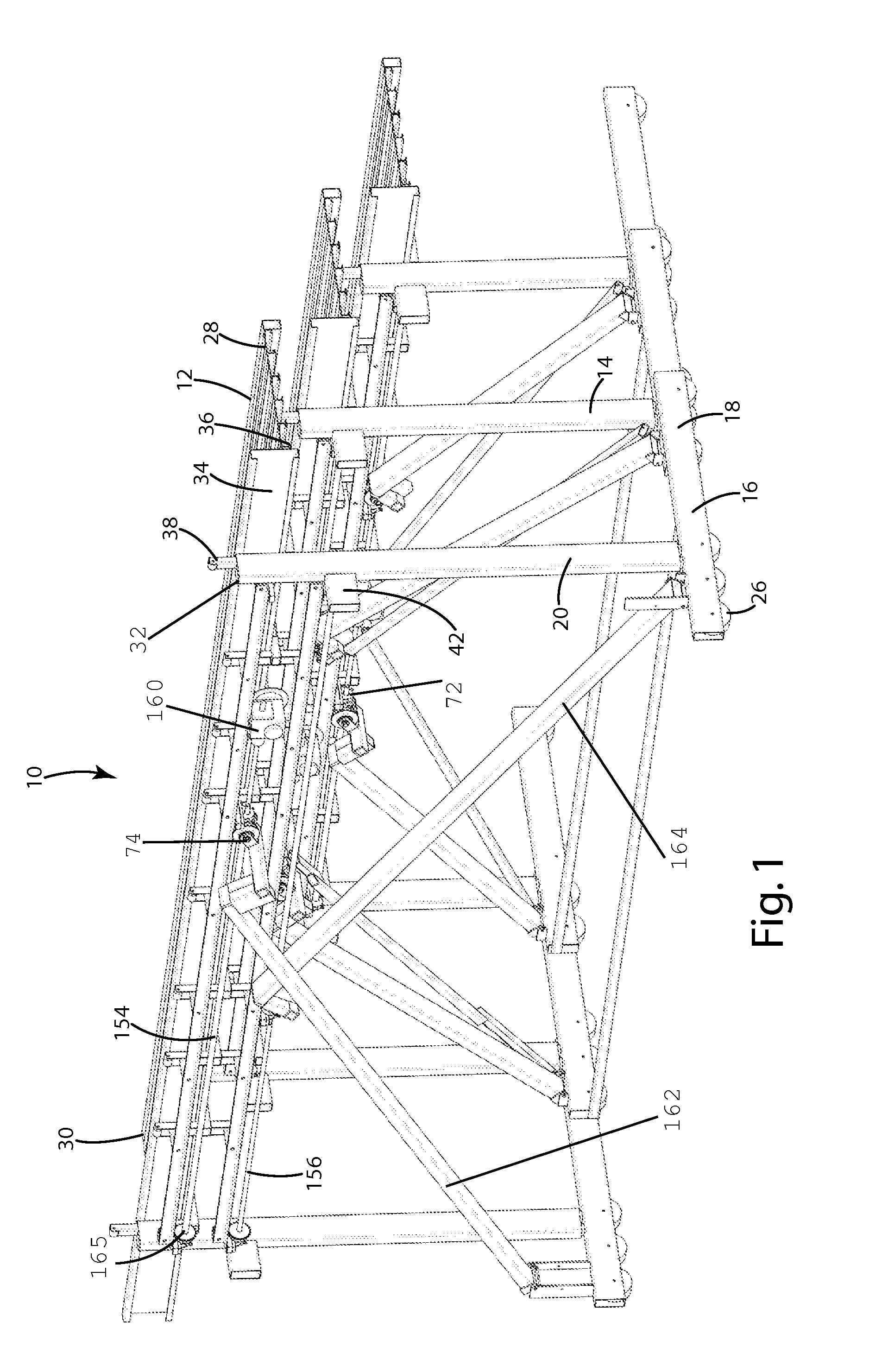

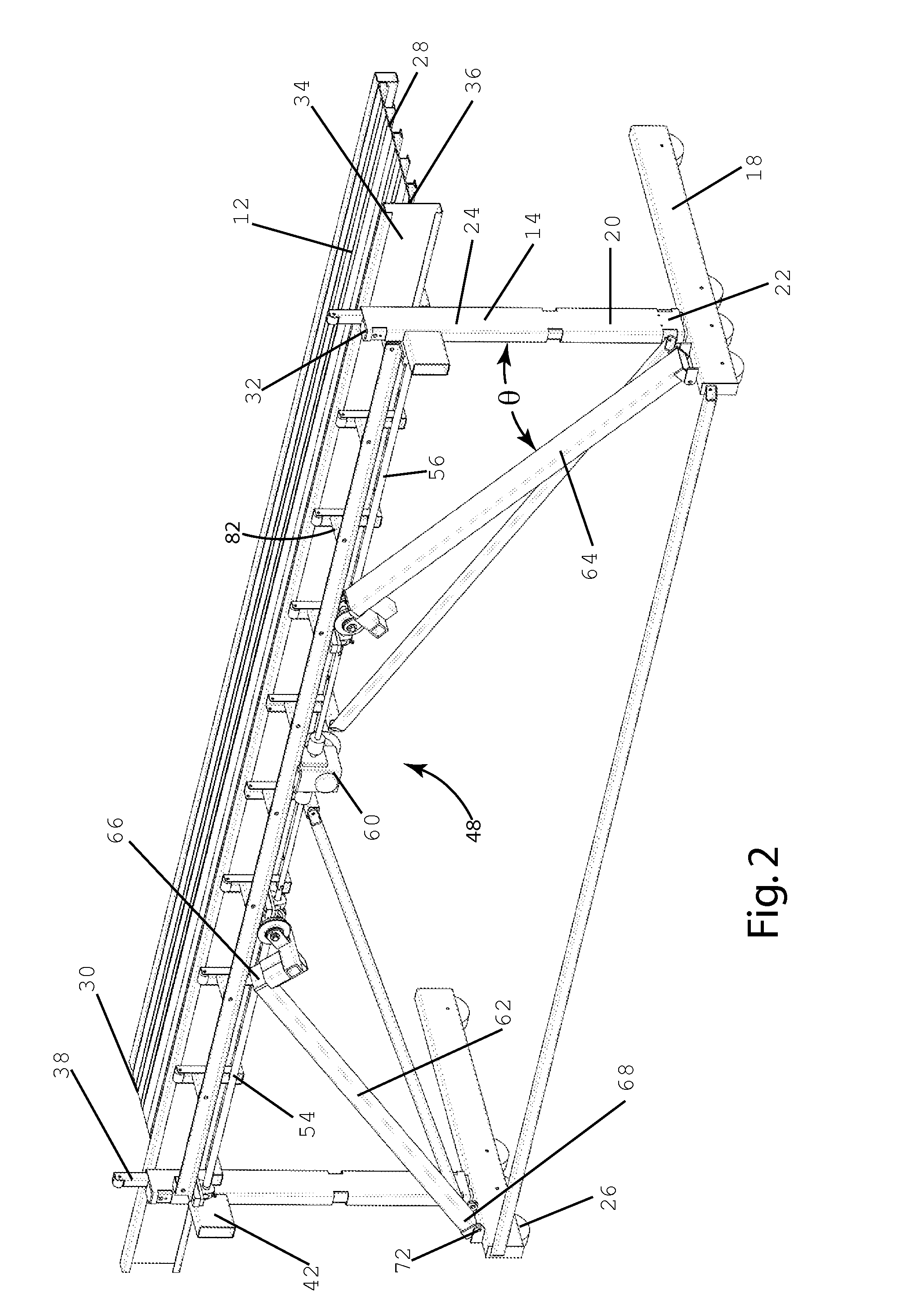

[0015]A variable rise platform seating system according to one embodiment of the present invention is shown in FIG. 1 and generally designated 10. In general, the described embodiment uses a swing arm mechanism to lift the deck surface of a telescopic platform. As shown in FIG. 1, each platform seating system 10 includes a generally horizontal platform deck 12 attached to a support structure 14. The support structure 14 may be movable, such that multiple platform systems 10 can be moved between an extended position (shown in FIG. 1) and a retracted position (not shown) in which the platform decks 12 and their support structures 14 are nested with each other. Each platform system 10 is capable of vertical movement between a lowered position, shown in FIG. 2, and a raised position, shown in FIG. 2a. The platform system 10 is moved between the raised and lowered positions by movement of swing arms between a canted position and a vertical position.

II. Structure

[0016]The suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com