Baseball bat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

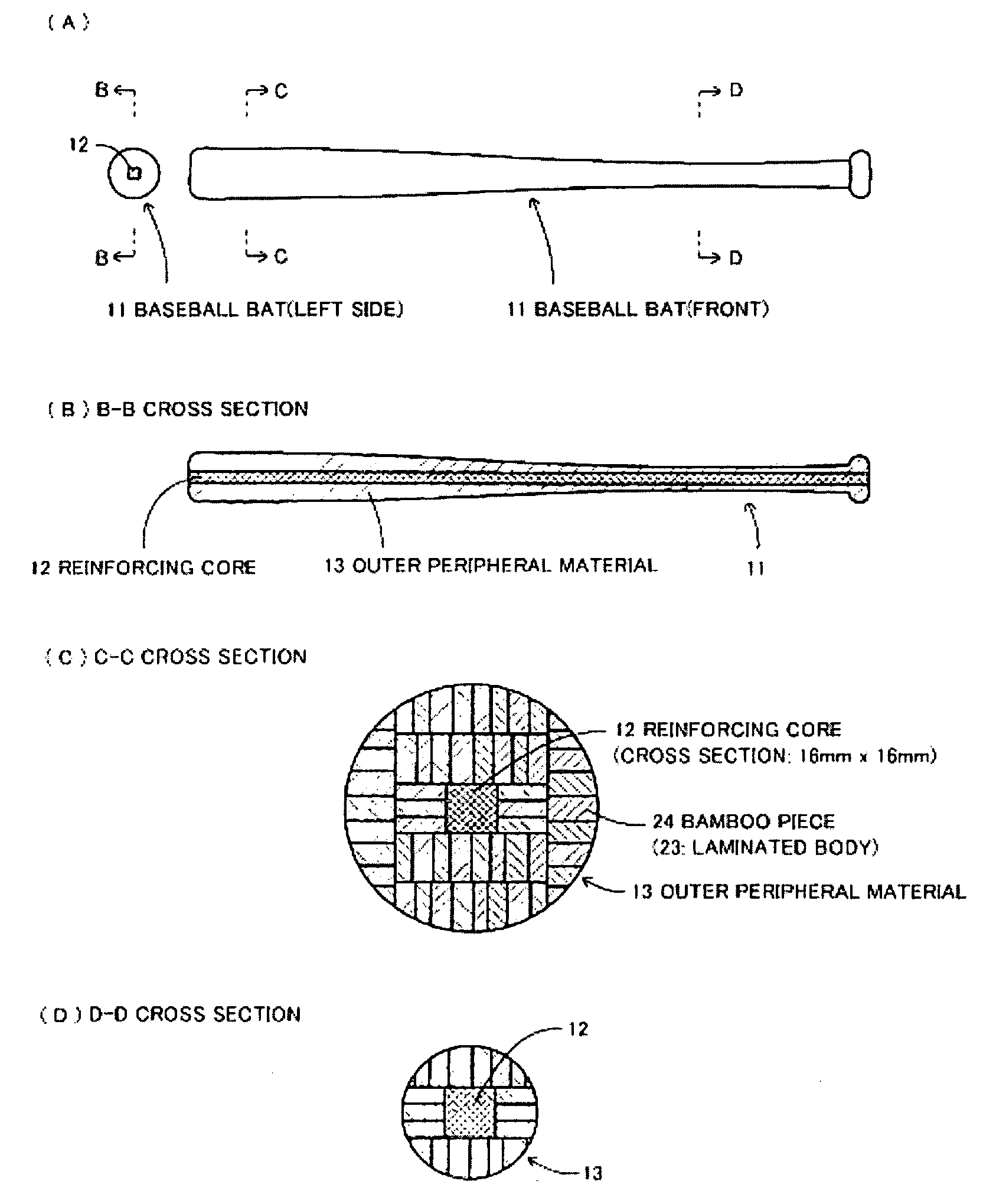

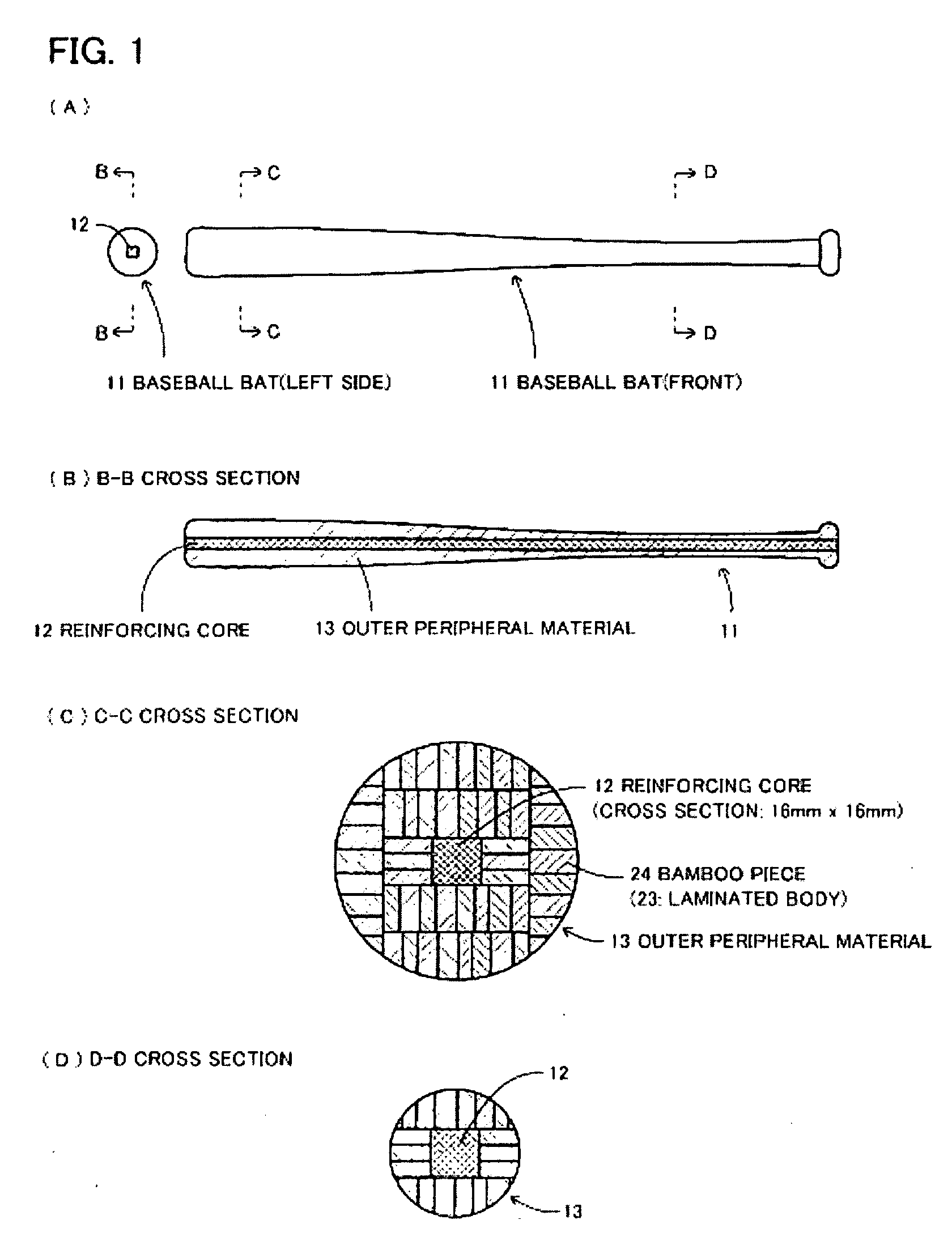

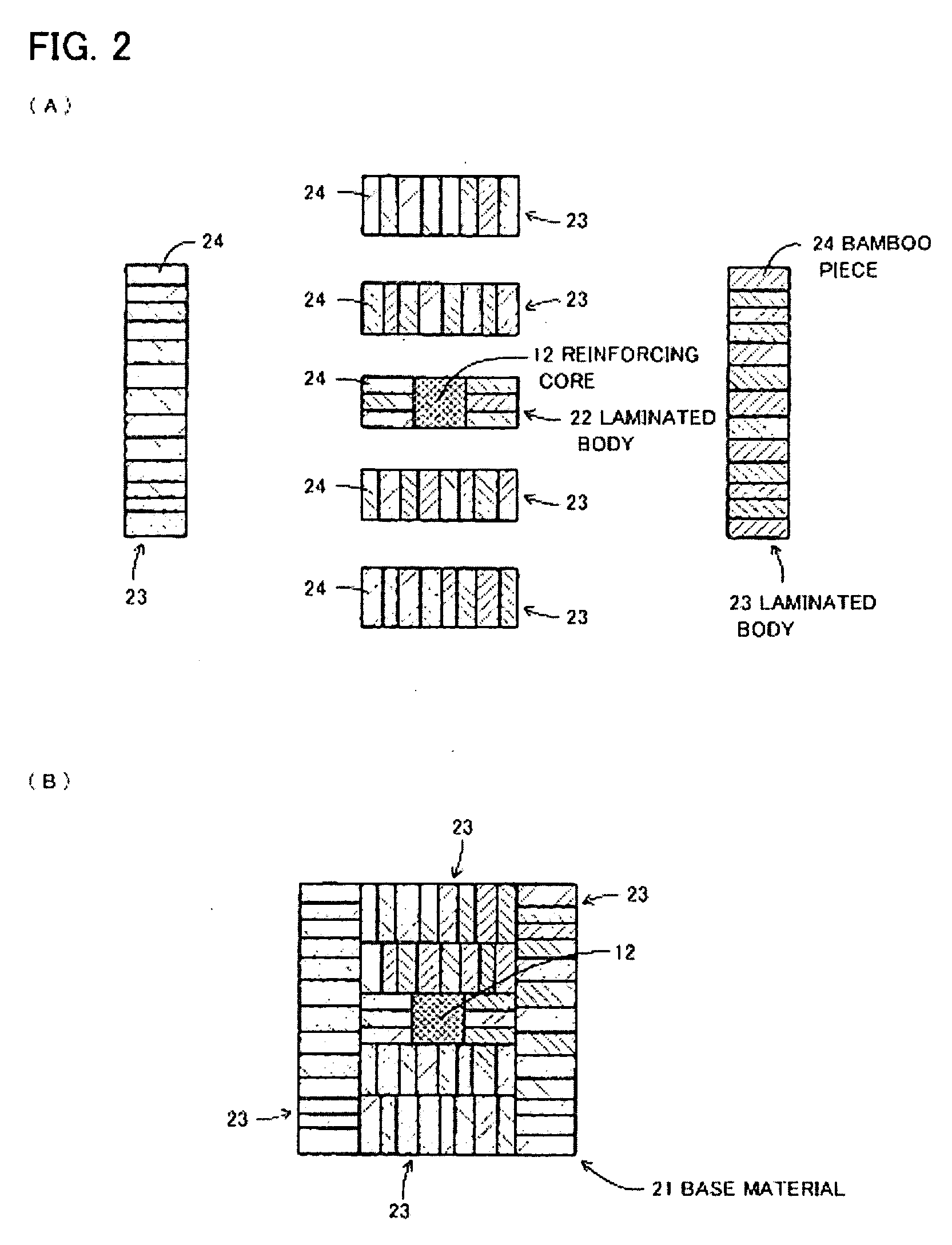

[0052]FIG. 1 is views showing a construction example of a baseball bat in accordance with the present invention, in which a reinforcing core has a square cross section, FIG. 1(A) being a front view and a left side view, FIG. 1(B) being a sectional view taken along the line B-B of FIG. 1(A), FIG. 1(C) being a sectional view taken along the line C-C of FIG. 1(A), and FIG. 1(D) being a sectional view taken along the line D-D of FIG. 1(A). A baseball bat 11 in accordance with the present invention has a construction such that a reinforcing core 12 having a square cross section, which is arranged in the center so as to penetrate both ends of the bat, and an outer peripheral material 13 consisting of bamboo pieces 24 is provided on the outside of the reinforcing core 12 so as to surround the reinforcing core 12. In FIG. 1, natural hickory is used as the reinforcing core 12. This reinforcing core 12 is made by sawing raw timber so as to have a square cross section having one side length of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com