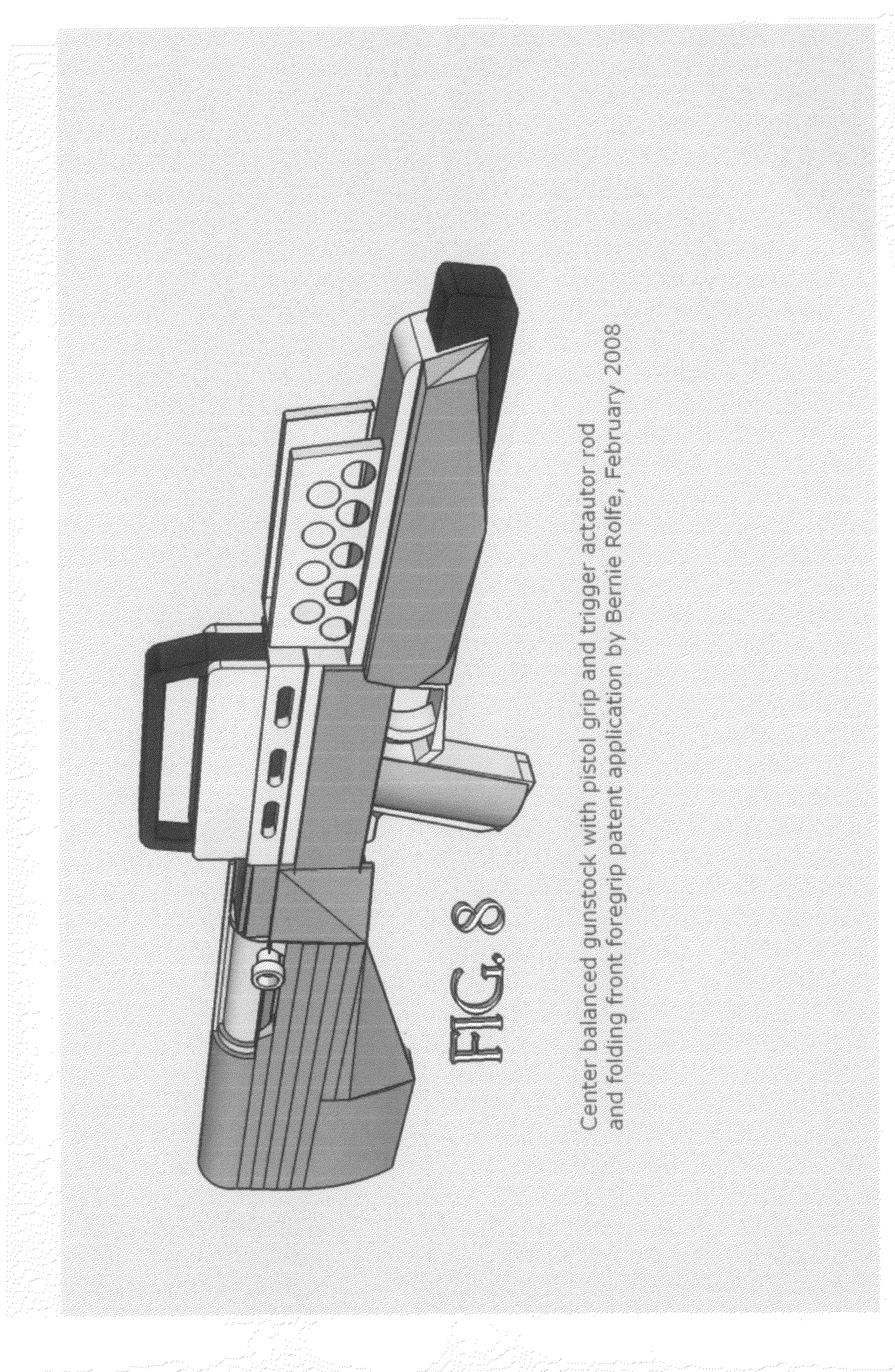

Center balanced gunstock with pistol grip and trigger actuator rod and folding front foregrip

a pistol grip and actuator rod technology, applied in the field of aftermarket gun grips, can solve the problems of incident wood warpage, wood affecting the accuracy sometimes required, and wood tends to warp, and achieve the effect of facilitating the removal of the original bolt cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

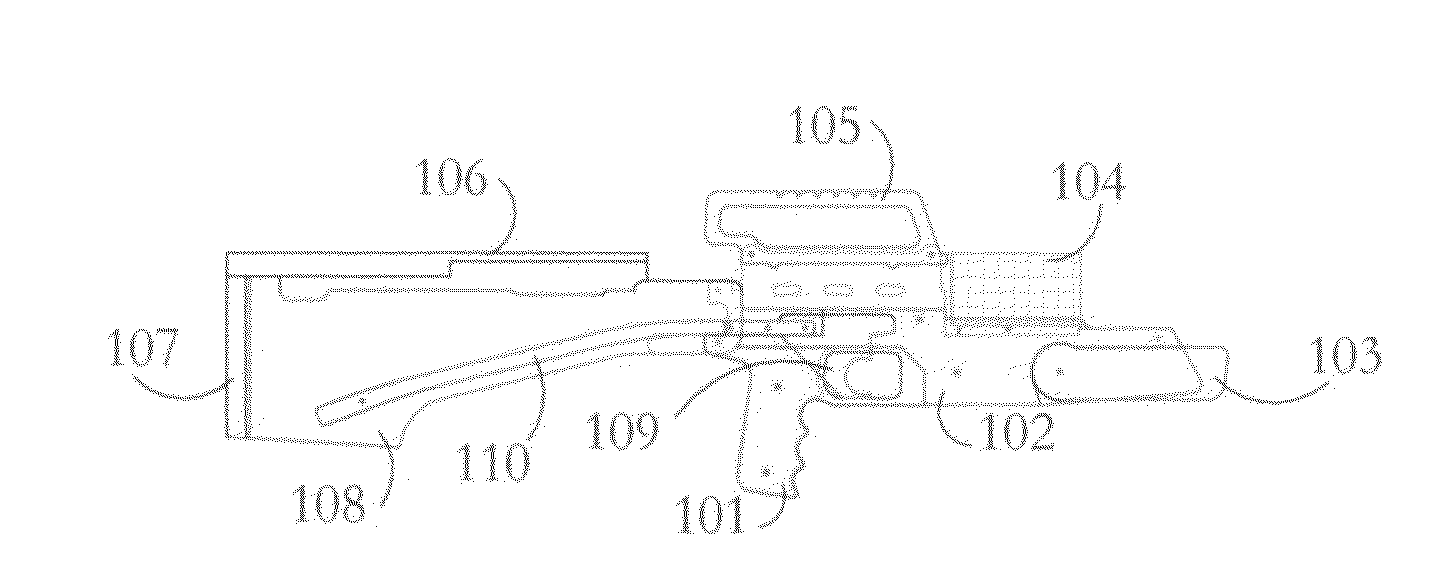

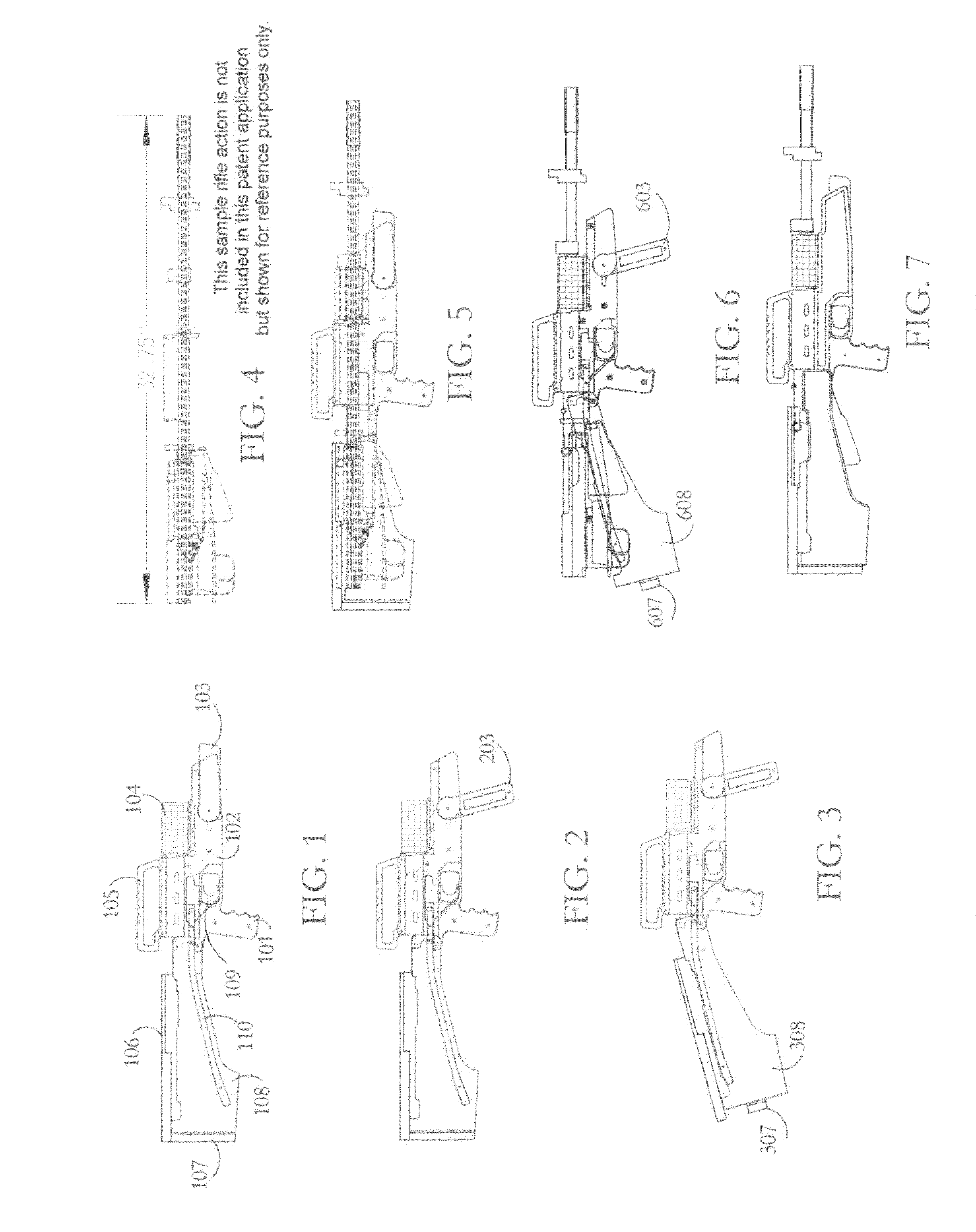

[0022]In FIG. 1, a stock pistol grip 101, attached to the stock fore end 102 with operable fore grip 103, with handguard 104, integral scope mount 105, gas shield 106, stock butt plate release mechanism 107, buttstock 108, trigger section 109 and trigger actuator rod 110 are shown as integral parts of the center balanced rifle stock, attached in a manner to accommodate the fit and various operations of this patent.

[0023]Other prior art rifle stocks were normally one-piece units simply designed to fit, as tightly as possible, the rifle receiver and barrel and gripped as a club or stick.

[0024]According to the invention, the relocated center of balance due to the restructuring of the handling grips, fore end and butt stock and resulting center of balance and associated recoil forces, provide an ergonomic structure to better accommodate ease of handling and a more pleasurable shooting experience.

[0025]In FIG. 2, the operable foregrip 203 is shown in dropped position.

[0026]In FIG. 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com