Stack damper

a damper and stout technology, applied in lighting and heating apparatus, ventilation systems, heating types, etc., can solve the problems of increasing the associated energy costs required to run the facility, large constant volume of air to be discharged,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

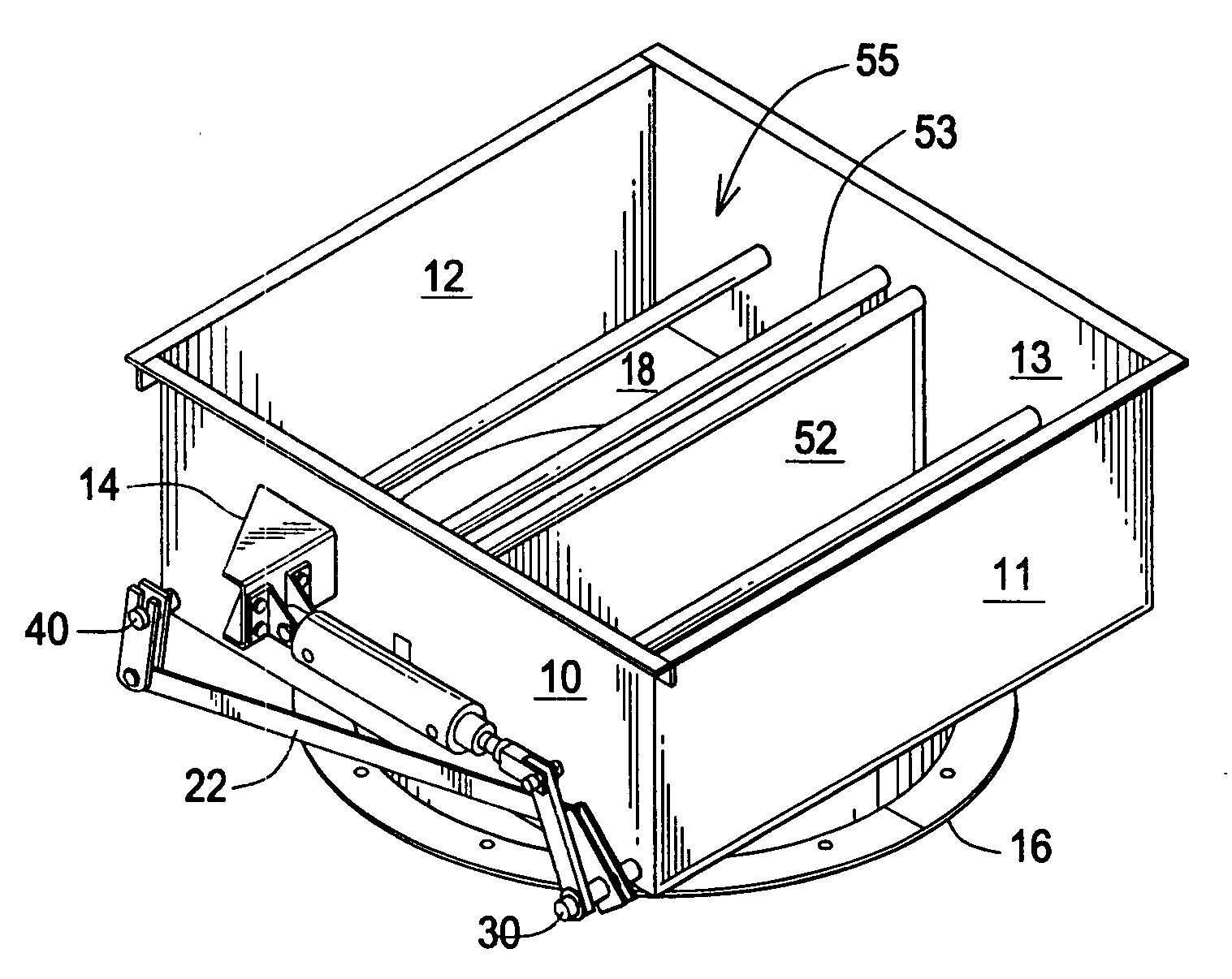

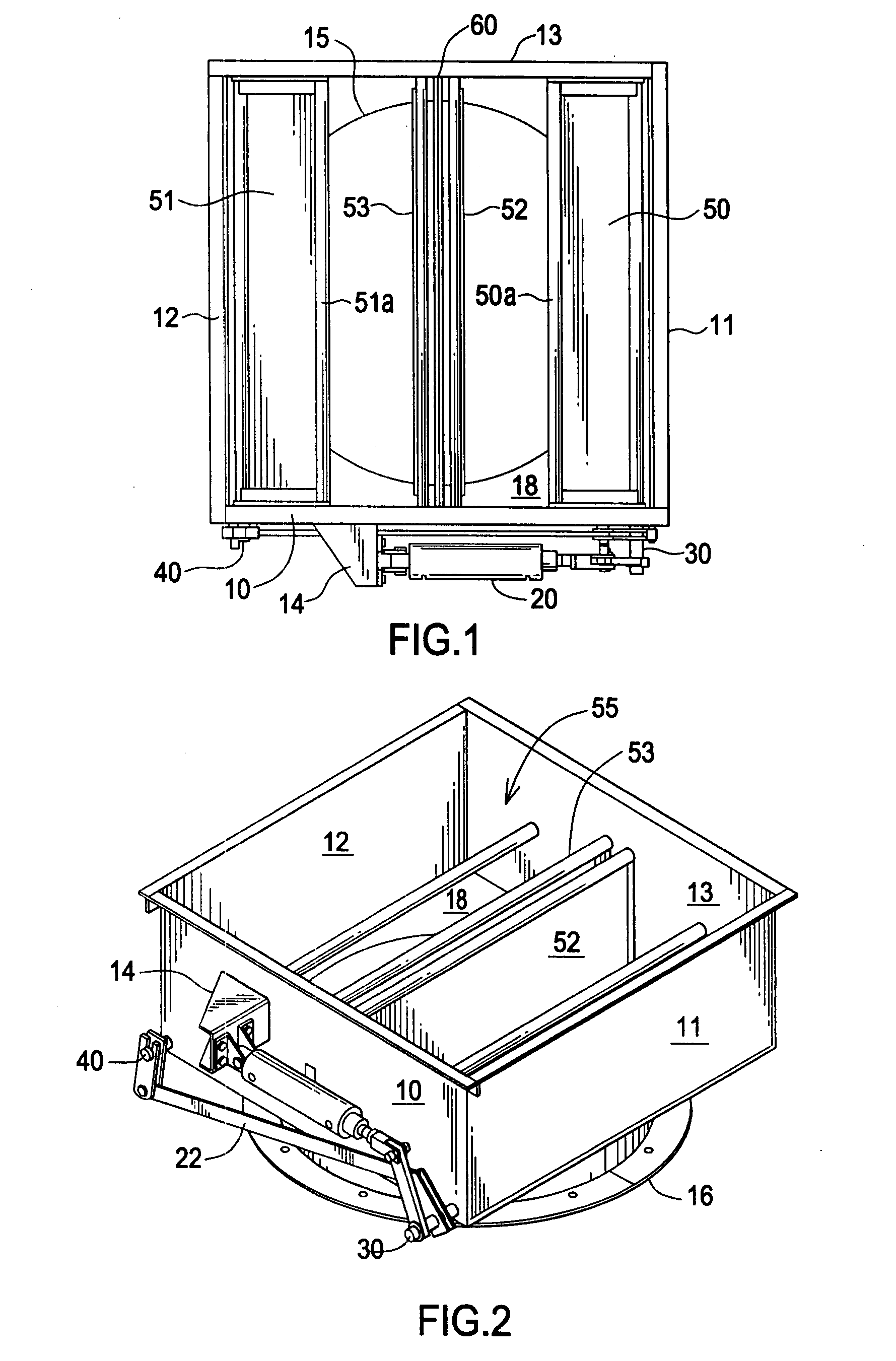

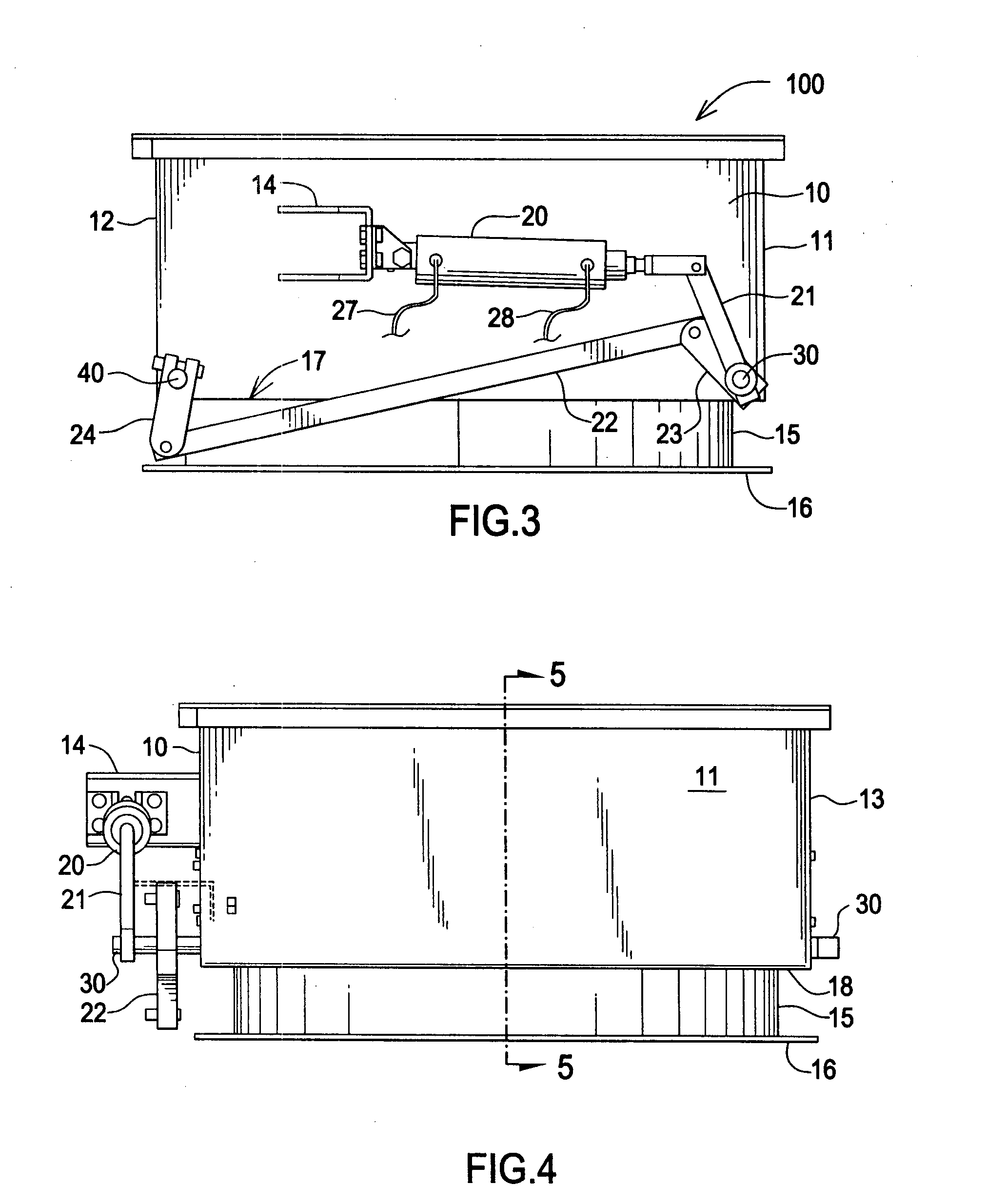

[0022]FIG. 1 is a plan view of the damper. Damper 100 comprises a duct defining an air flow path and generally having sides 10, 11, 12, and 13 arranged in any form suitable for installation in air handling system ductwork. Sides 10, 11, 12, 13 are connected together in a substantially air tight manner to avoid air leakage. Mounting member 14 is attached to side 10. An end of air piston 20 is connected to mounting member 14. Sides 10, 11, 12, 13, 14 and skirt 15 and flange 16 preferably comprise galvanized metal, but may also comprise any other material suitable for HVAC service. Portion 18 is disposed between sides 10, 11, 12, and 13 and skirt 15.

[0023]Damper blade 50 is attached in a cantilever fashion to damper shaft 30. Damper blade 51 is attached in a cantilever fashion to damper shaft 40. Vane 52 is fixedly connected between sides 10 and 13. Vane 52 is fixedly connected between sides 10 and 13. Vanes 52 and 53 are substantially parallel. Damper blades 50 and 51 are substantiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com