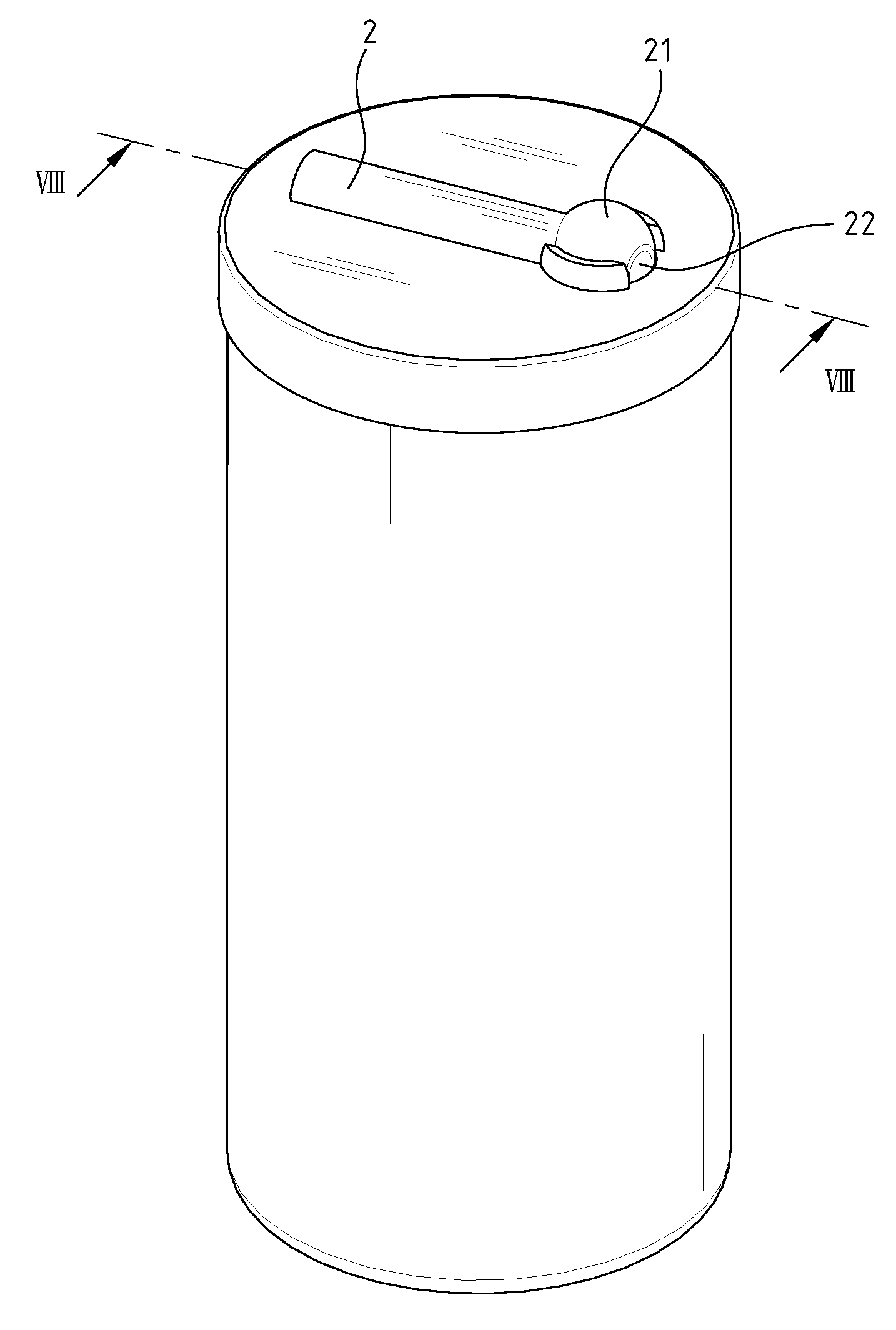

Cap With Suction Unit For Cup

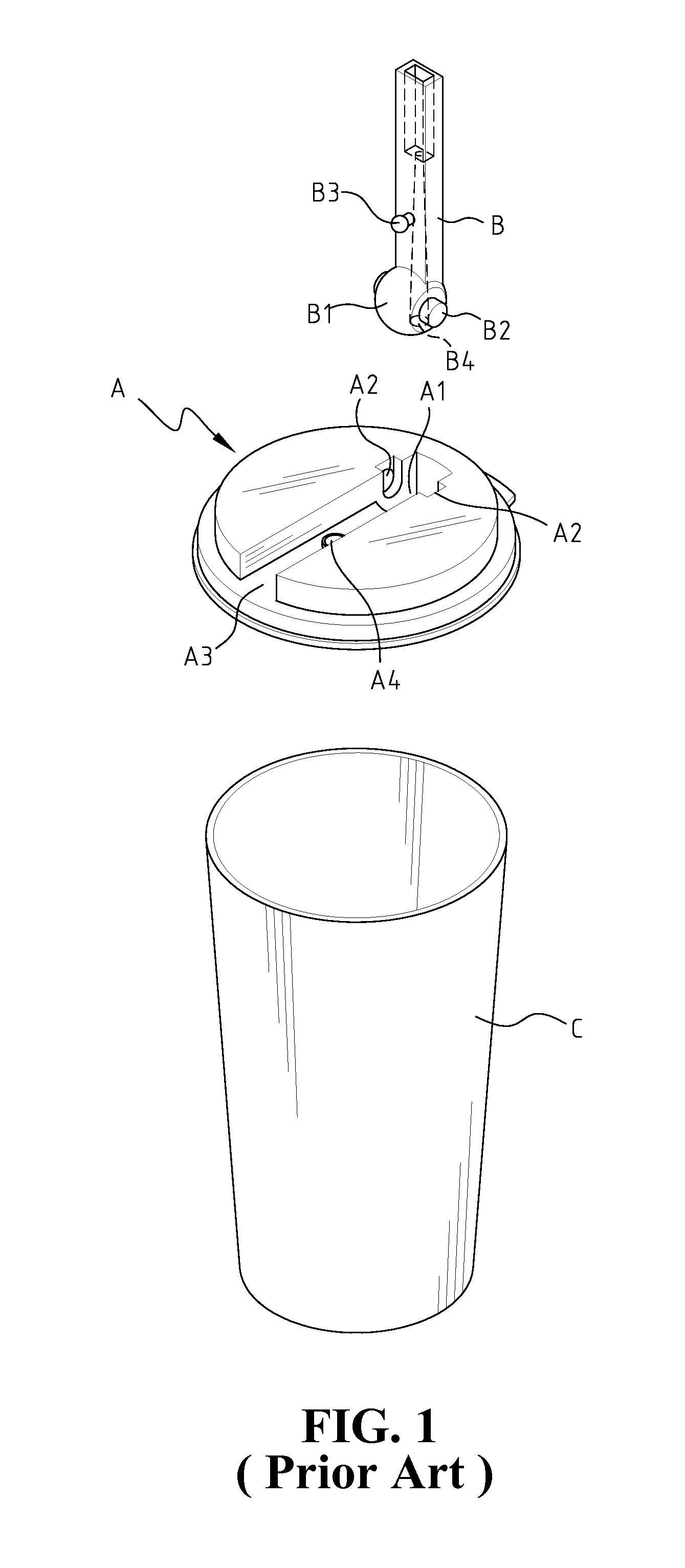

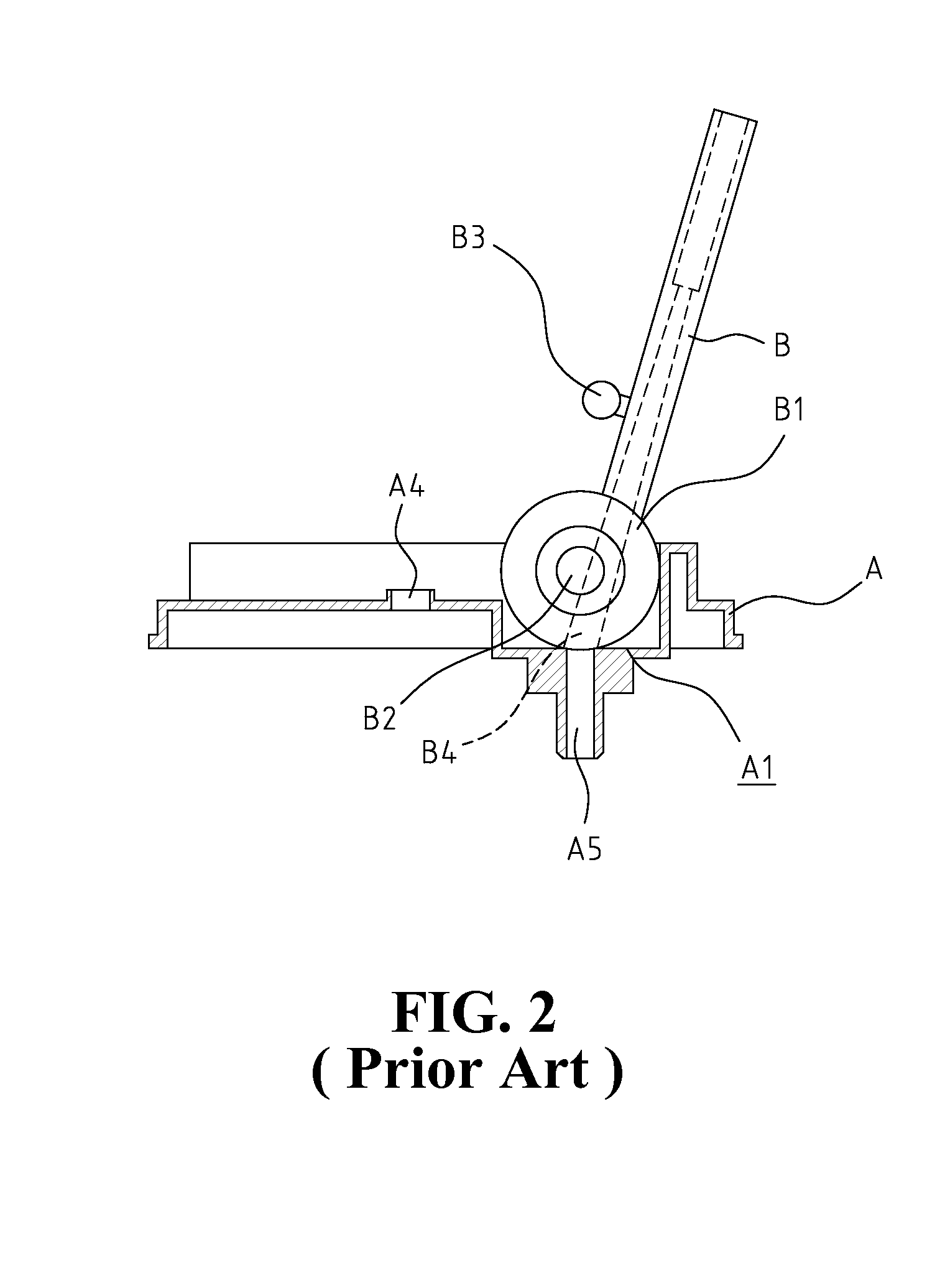

a technology of suction unit and cap, which is applied in the field of caps with suction units for cups, can solve the problems of not being well sealed in the recess ab>1/b> outlet ab>5/b>

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]With reference to the drawings and in particular to FIG. 4, a cap with a suction unit for a cup in accordance with the present invention, comprises a cap 1 having a semi-spherical recess 11 defined in a top thereof, and an outlet 15 is defined through an inner end of the semi-spherical recess 11. At least one first air hole 13 is defined through the cap 1 and an inner periphery of the semi-spherical recess 11. Preferably, the at least one through hole 13 is defined in a lateral surface of the semi-spherical recess 11. An opening is defined in the top of the semi-spherical recess 11 and a diameter of the opening is smaller than a diameter of the semi-spherical recess 11. In a preferable embodiment, two flanges 12 extend from the top of the cap 1 and the opening is located between the two flanges 12. Each flange 12 includes an inner surface which has the same curvature as the semi-spherical recess 11. An elongate groove 14 is defined in the top of the cap 1, and the elongate gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com