Tool Head Structure

a tool head and tool head technology, applied in the direction of manufacturing tools, wood boring tools, transportation and packaging, etc., can solve the problems of screw head damage, increase the cost, and reduce the whole work efficiency, and achieve the effect of easy engagement with the screw head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The present invention will be clearer from the following description when viewed together with the accompanying drawings, which show, for purpose of illustrations only, the preferred embodiment in accordance with the present invention.

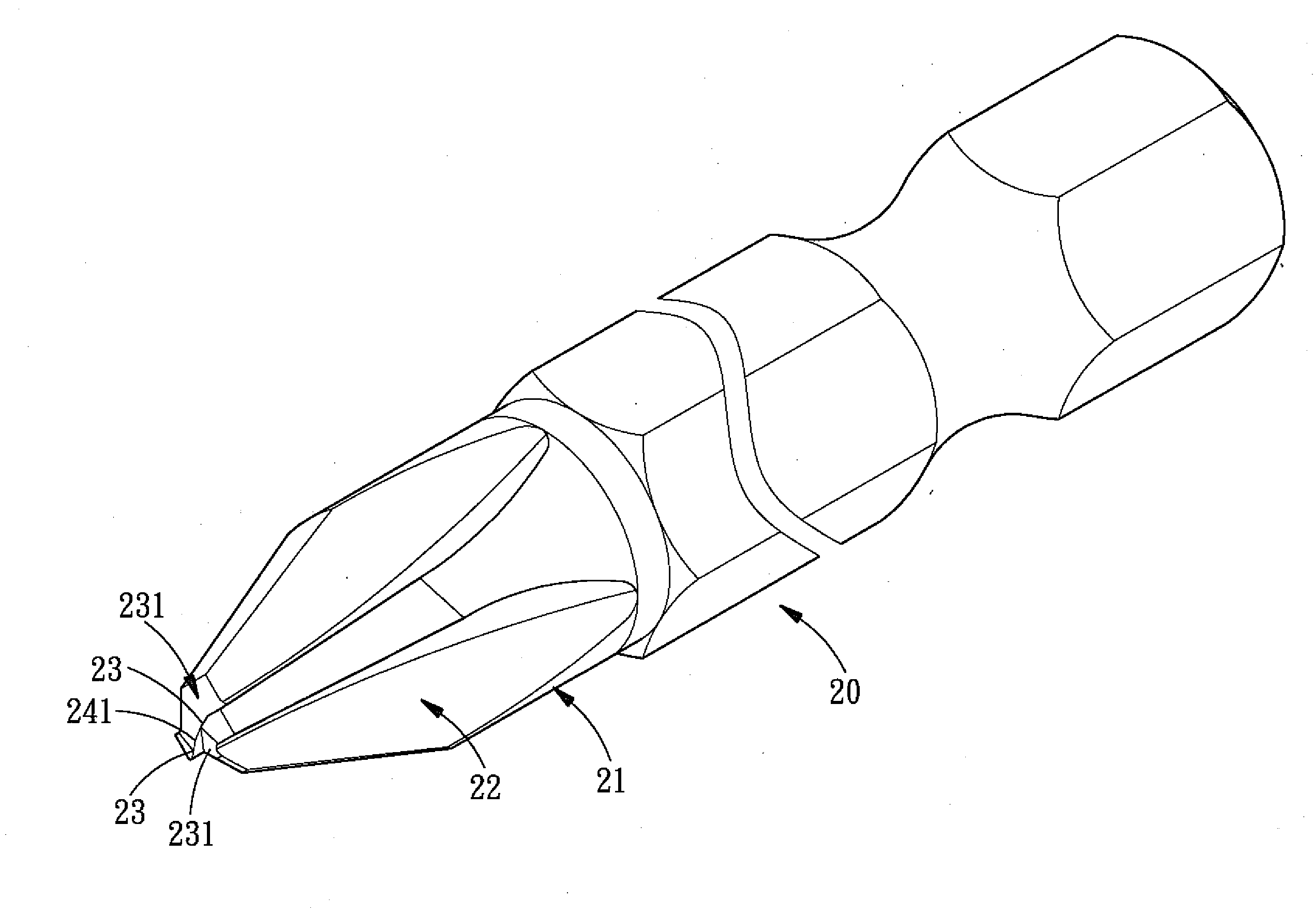

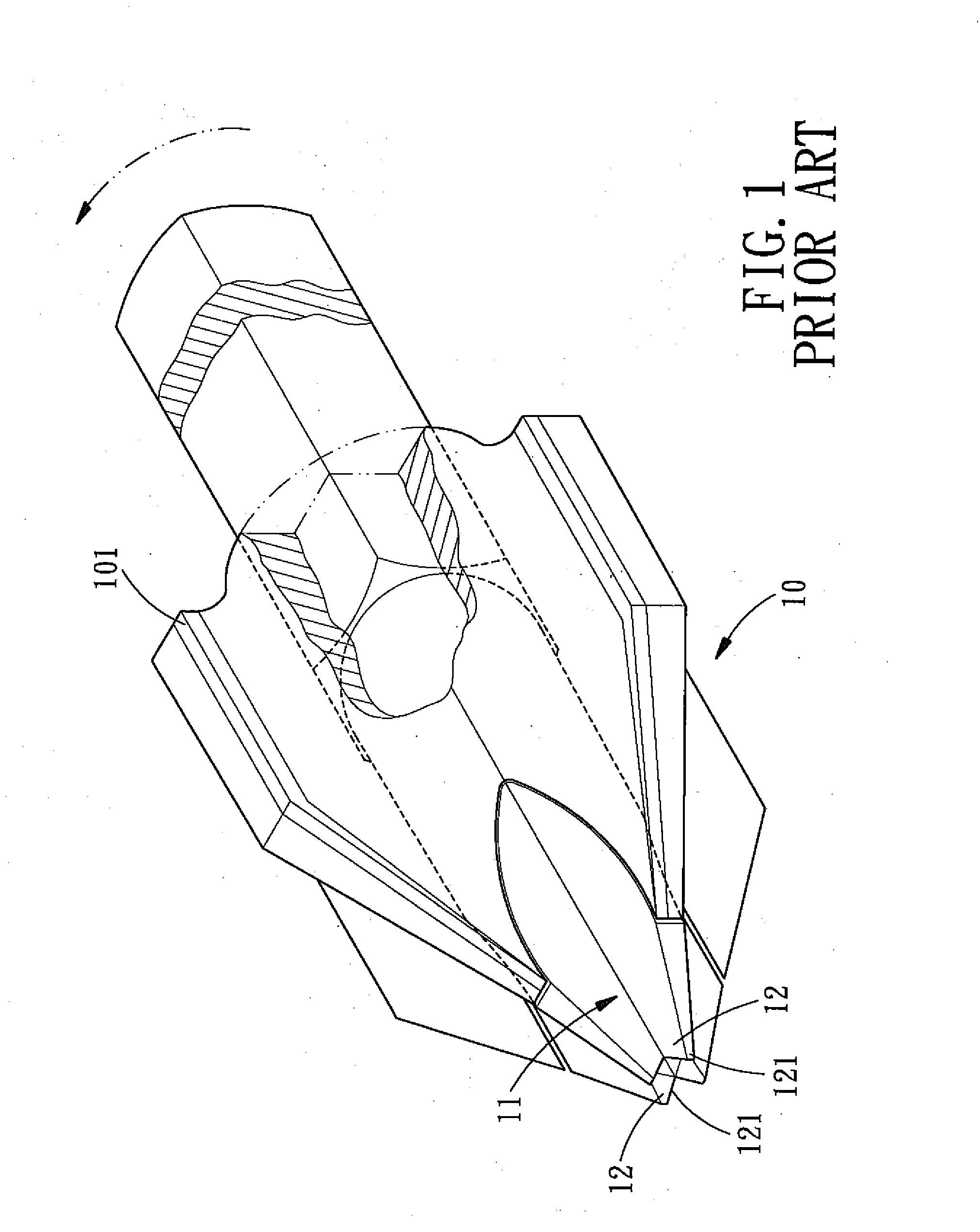

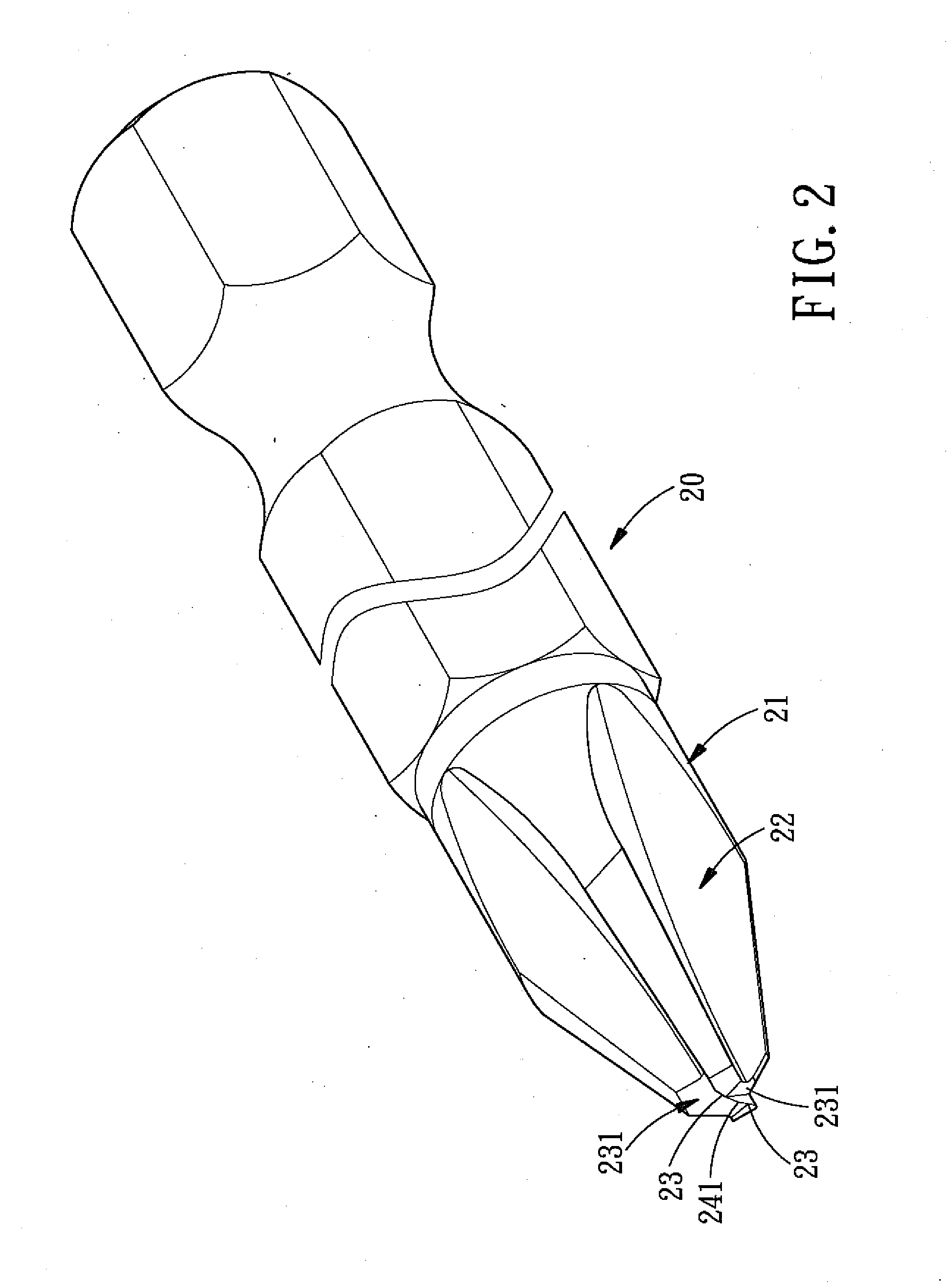

[0029]Referring to FIGS. 2-4, a tool head structure 20 in accordance with the present invention is integrally formed. One end of the tool head structure 20 is in the form of a hexagonal column for assembling with the relevant tool, and the other end of the tool head structure 20 is equally formed with four protruding driving portions 21 shaped correspondingly to the cross-shaped screwing recess 31 of the screw 30. Between each two adjacent protruding driving portions 21 is formed a concave engaging portion 22. The tool head structure 20 is characterized in that:

[0030]Two cutting edges 23 are formed at the convergence center of the protruding driving portions 21 and the engaging portions 22. The two cutting edges 23 are parallel to each other in o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com