Packaging Article

a technology for packaging and beverage containers, applied in the field of beverage containers, can solve the problems of not being able to achieve the practical solution to the problem, and yet no beverage container that fulfils these aims has been produced, so as to prevent the egress of gas, prevent the contamination of beverage, and prevent the effect of staleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0051]The second embodiment shown in FIGS. 4 and 5, comprises a container body 21, a foil 22 covering the mouth of the container body 21 and a cap 23 fitted onto the container body 21 over the foil 22.

[0052]The container body has a lip 24 and the foil 22 extends over the lip 24. The cap is preferably a snap-fit plastic cap but a metal cap may also be used which can be crimped over the lip 24.

[0053]The cap 23 is shaped so as to be a snap-fit over the lip 24 of the container body 21. Alternatively, the cap 23 may be shrunk fit onto the container body 21. The foil 22 is preferably secured to the lip 24 by localised induction heating to melt a plastic layer on the underside of the foil and so weld it to the lip 24. Alternatively, or additionally, the foil 22 is crimped over the edge of the lip 24. If required, it may also be sealed to the external surface of the container. The foil is also preferably secured to the cap 23 by localised heating to melt a plastic layer on the upperside of ...

fourth embodiment

[0062]FIG. 8 shows the invention in which a foil is used to seal a wide-mouth container in conjunction with closure means or a cap which protects and / or re-enforces the foil.

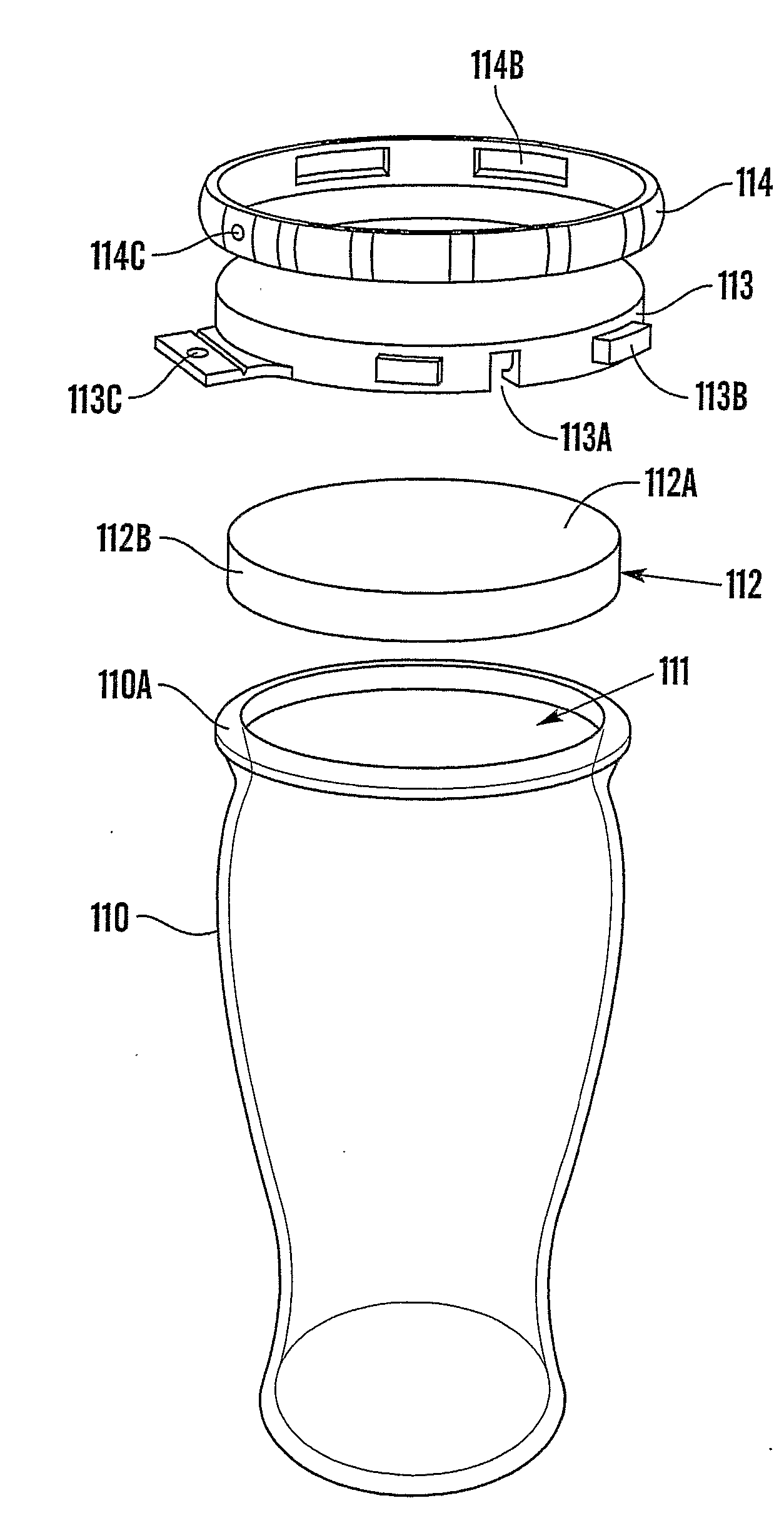

[0063]FIG. 8A shows a container 110 with an opening 111 and closure means comprising a foil 112, cap 113 and collar 114.

[0064]The container is shaped to resemble a beer glass and has a lip 110A around its opening 111. The foil has a top part 112A and skirt 112B. The cap 113 includes one or more gaps 113A in its periphery, has thread-like formations 113B on its external surface and preferably has tamper evident clips 113C attached thereto by a living hinge and carrying a projection. The collar 114 comprises threadlike formations 114B on its inner surface for engaging with the thread-like formations 113B of the cap and a recess and hole 114C for receiving each clip and projection 113C.

[0065]As shown in FIG. 8B, the foil 112 is held in contact with the lip 110A by the cap 113. The cap 113 has an internal projecting...

fifth embodiment

[0068]FIG. 9C shows a vertical sectional view through a fifth embodiment in which the closure means comprises a foil 150 and a collar 151 and FIGS. 9A and 9B show perspective and plan views of the collar 151.

[0069]The collar comprises a first part 151A with a gap therein and a second part 151B which can be connected to the first part 151A to join the ends of the first part 151A. The second part 151B hooks to one end of the first part 151A and has an over-centre mechanism 151C such that when moved to the closed position it remains in this position and puts the collar 151 under tension so as to clamp it more securely about the container 152 and foil 150. As shown in FIG. 9C, the collar 151 is shaped to engage under a lip 152A of container 152 and is arranged to grip the foil 50 tighter as the collar is tightened.

[0070]Part 151B is provided with a tab 151D which may be lifted like a conventional ring-pull to break the collar at one or more weak points 151E when it is desired to remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com