Fuell cell system and operation method of fuel cells

a fuel cell and fuel cell technology, applied in the field of fuel cell systems, can solve the problems of increasing the amount of steam, reducing the water content used for humidification, and unsatisfactory deterioration of the humidification performance of the humidifier, so as to enhance the humidification efficiency of the humidifier and increase the pressure of the exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

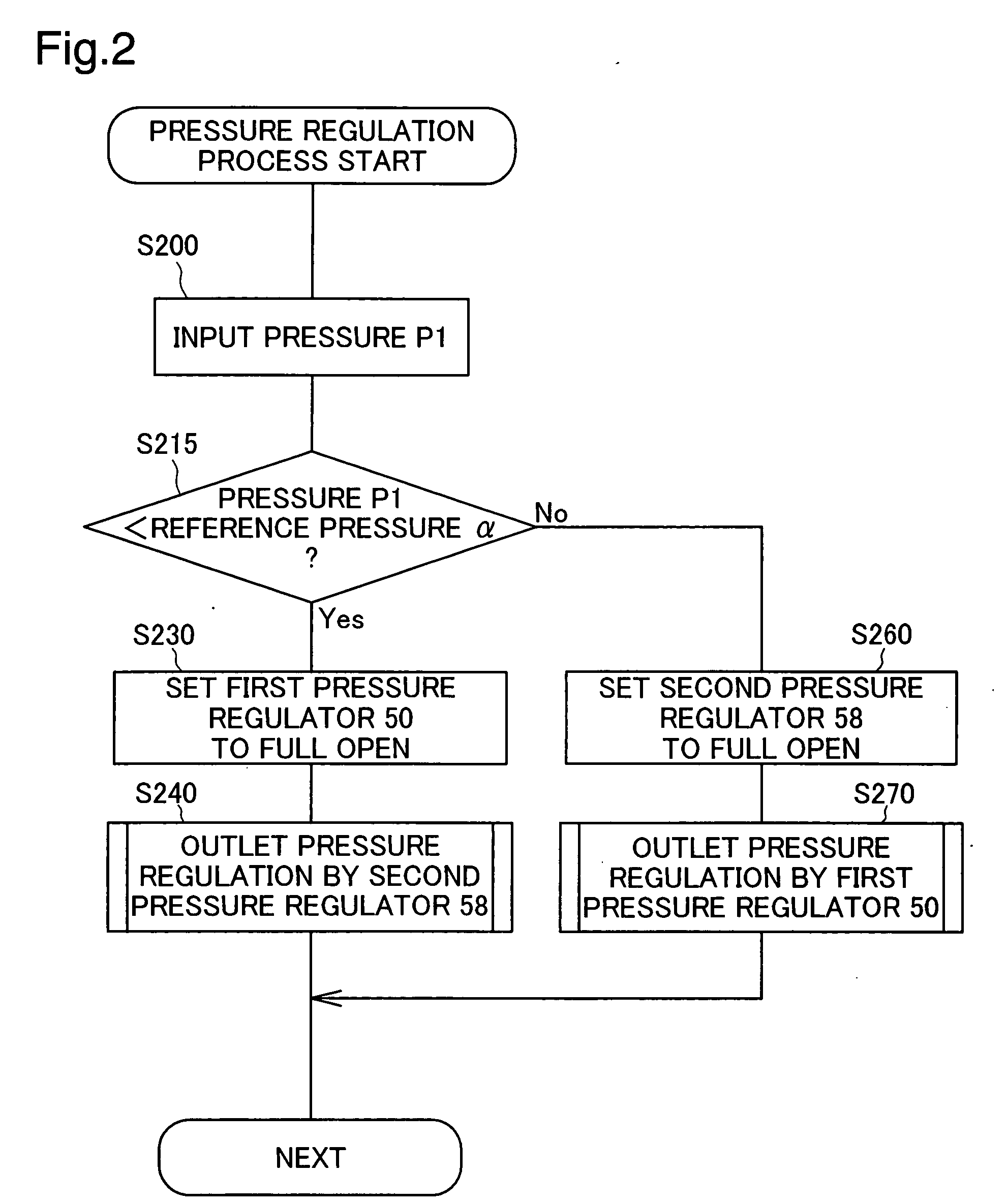

[0028] B. Pressure Regulation Process in First Embodiment

second embodiment

[0029] C. Pressure Regulation Process in Second Embodiment

[0030] D. Modifications

A. General Configuration of Fuel Cell System

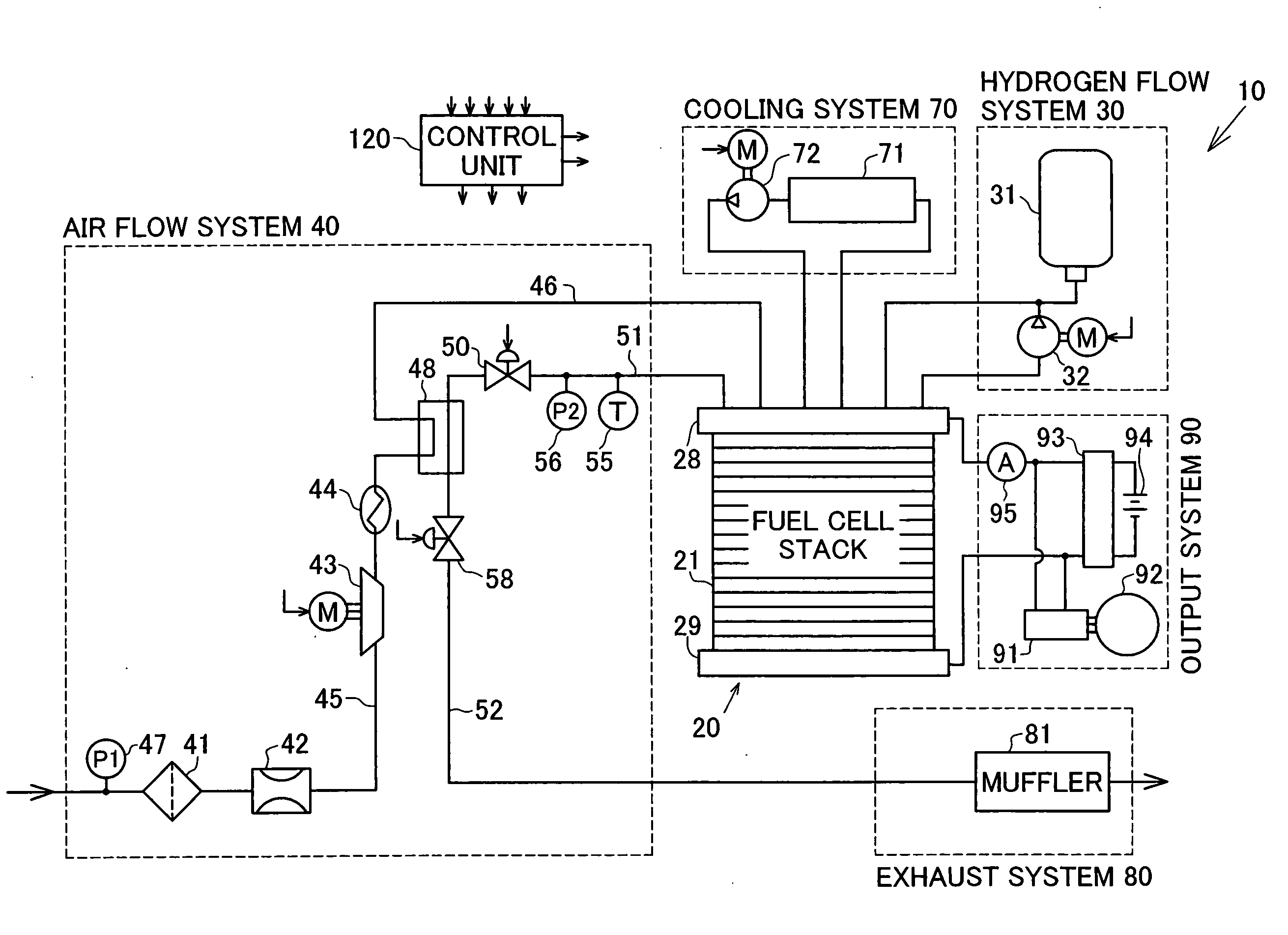

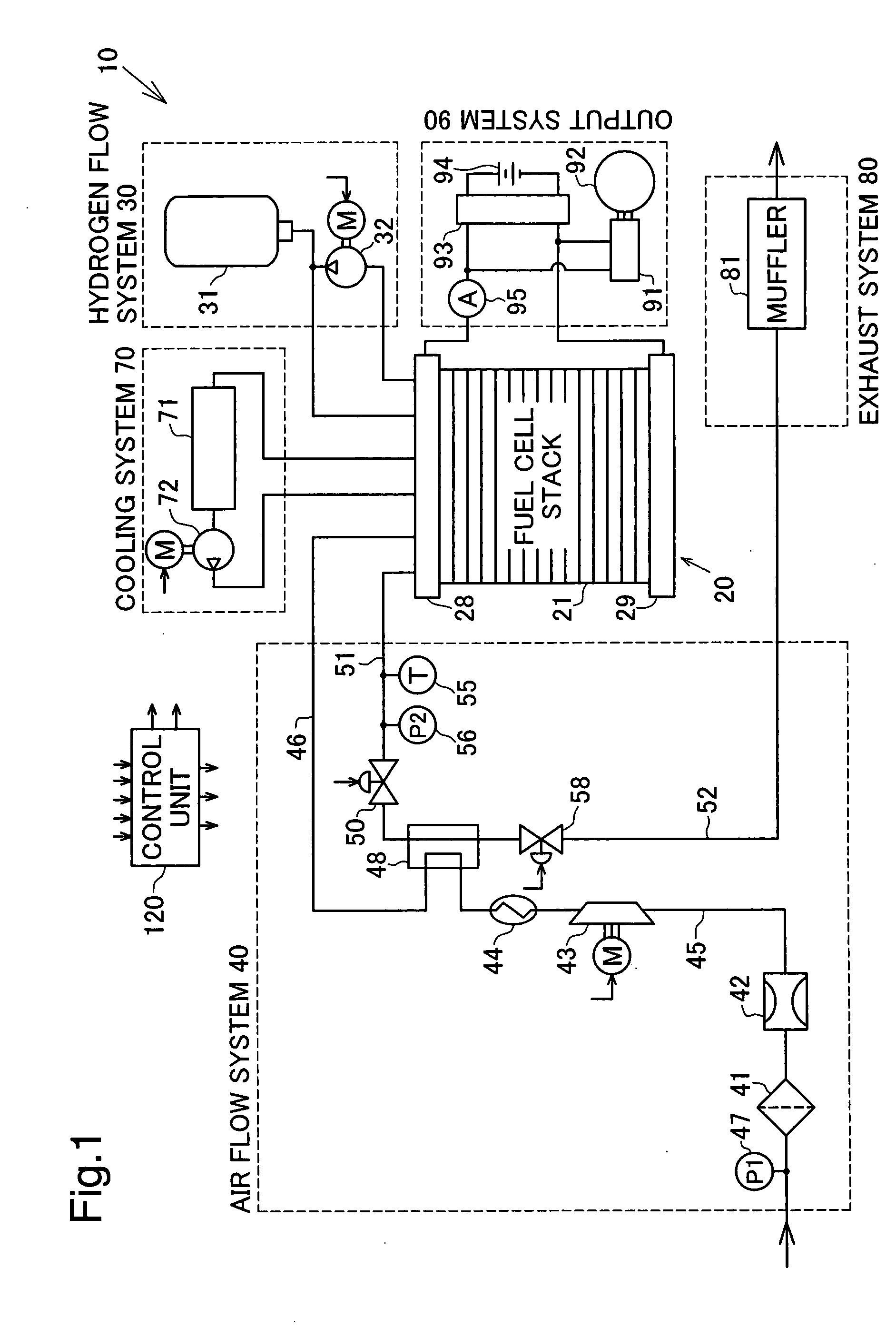

[0031]FIG. 1 schematically illustrates the configuration of a fuel cell system 10 embodying the invention. The fuel cell system 10 includes a stack of fuel cells or fuel cell stack 20 that receives supplies of hydrogen gas and the air as reactive gases and generates electric power through an electrochemical reaction of hydrogen with oxygen included in the air. The fuel cell system 10 is mounted on a vehicle (not shown) to work as a driving source for driving the vehicle with the electric power generated by the fuel cell stack 20. As illustrated, the fuel cell system 10 includes a hydrogen flow system 30 to feed the hydrogen gas to the fuel cell stack 20, an air flow system 40 to feed the air to the fuel cell stack 20, and a control unit 120 to control the constituents of the fuel cell system 10, in addition to the fuel cell stack 20.

[0032] The fuel cell st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com