Air passage device

a filter mat and air passage technology, applied in the field of air passage devices, can solve the problems of scarce play and laborious installation of such filter mats, and achieve the effect of quick exchange of filter mats and no large structural expenditur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

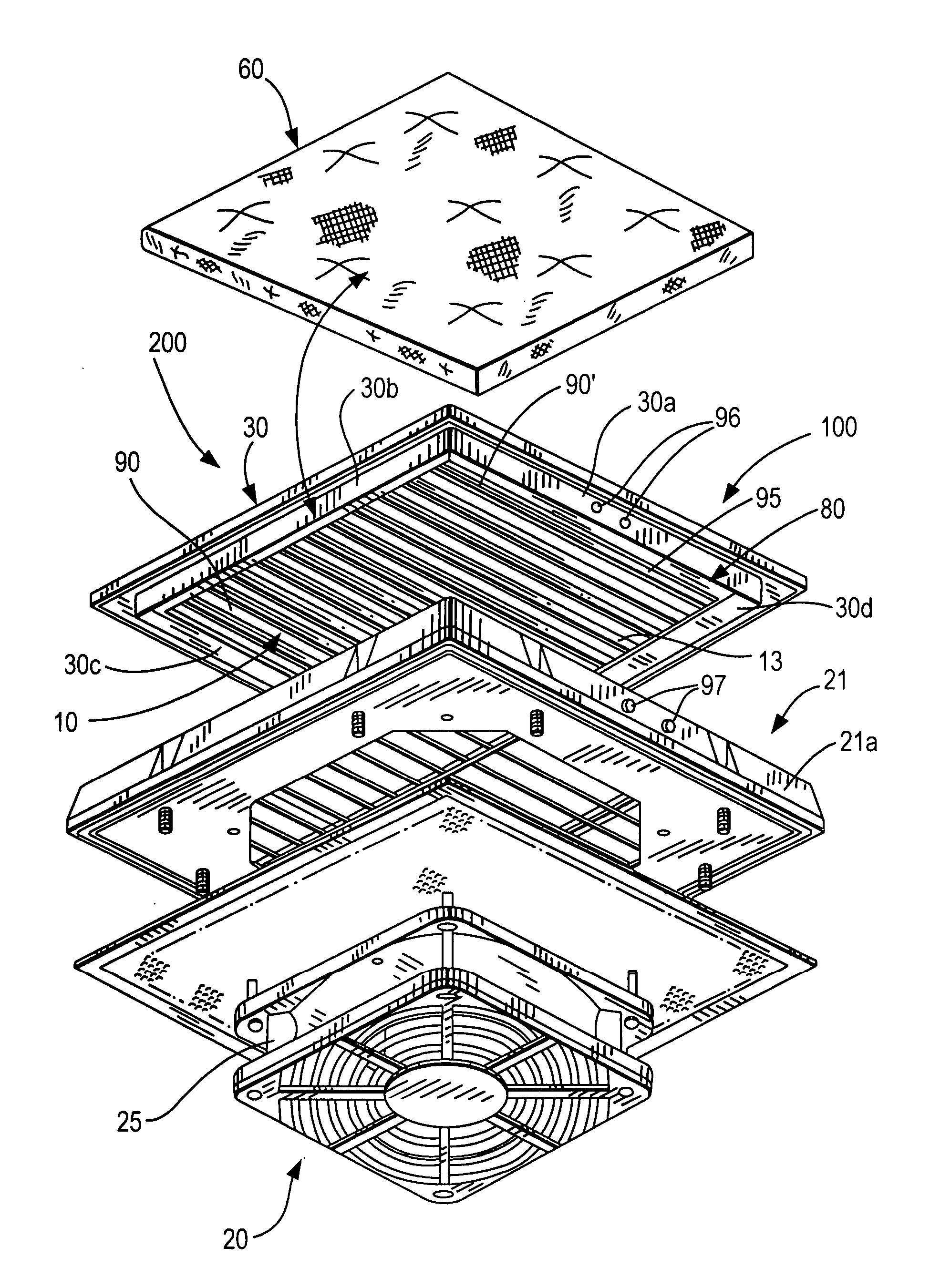

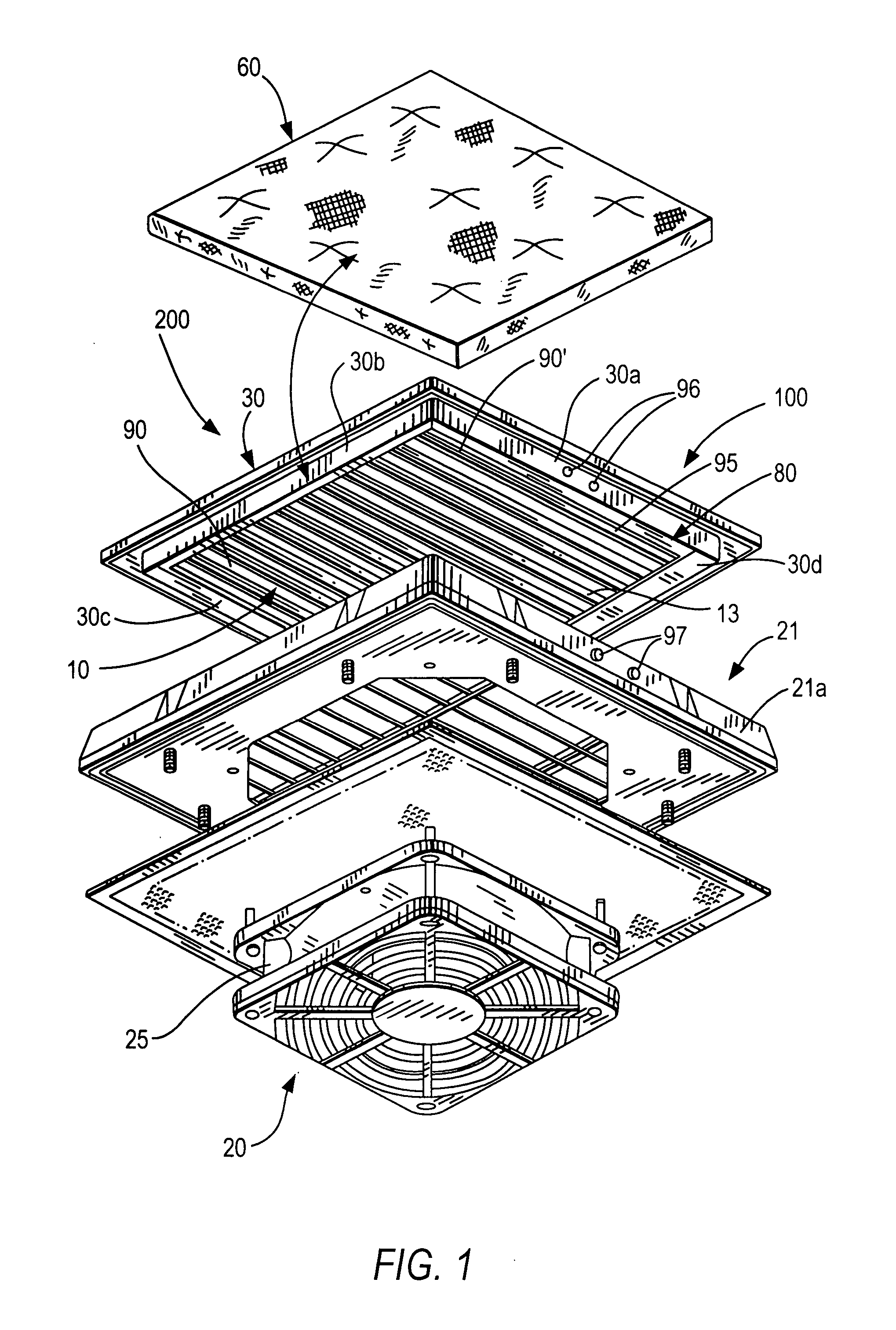

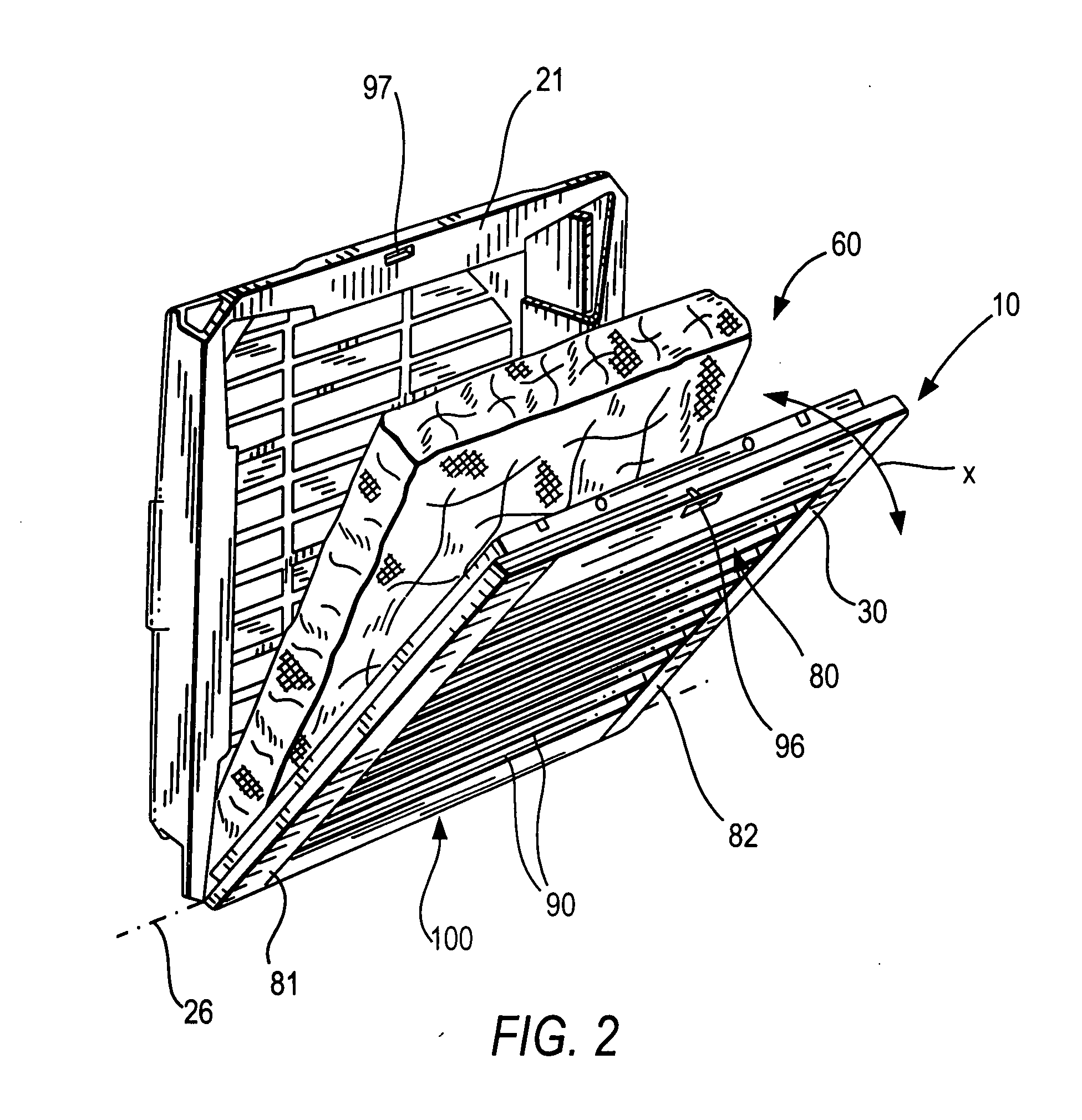

[0062] The air passage device 200 illustrated in FIG. 1 to 3 of the invention is able to be used in connection with a fan or ventilator as a filter fan and without a fan 20 as an outlet filter. The air passage device 200 is used in housings of components generating waste heat, such as switch boxes, electronics boxes, computer systems or suchlike, in which the air passage device 200 is incorporated in mounting openings 50 in a wall 51 of such a housing (FIG. 3).

[0063] The essential components of the air passage device 200 are a design cover 80 with a fan grid 10 with ventilation slits, which forms the front covering device 100 for a base housing 21, a fan support 25 for the fan 20, when the air passage device 200 is used as a filter fan (FIG. 1 to 3).

[0064] The covering device 100, which forms the fan grid 10, is constructed as a design cover 80 and consists of a frame-like housing 30, preferably with side walls 30a, 30b, 30c, 30d and with sheet elements 90, in which ventilation sli...

second embodiment

[0072] The air passage device 200 of the invention, illustrated in FIG. 10 to 12, is able to be used in connection with a fan or ventilator as a filter fan, and without a fan 20 as an outlet filter. The air passage device 200 is used in housings of components generating waste heat, such as switch boxes, electronics boxes, computer systems or suchlike, in which the air passage device 200 is installed in mounting openings 50 in a wall 51 of such a housing (FIG. 12).

[0073] The essential components of the air passage device 200 are a design cover 280 with a fan grid 210 with ventilation slits, which forms the front covering device 100 for a base housing 221 and a fan support 25 for the fan 20, when the air passage device 200 is used as a filter fan (FIG. 10 to 12).

[0074] The covering device 100, which forms the fan grid 210, is constructed as design cover 280 and consists of a frame 230 with side walls 230a, 230b, 230c, 230d and in the embodiment illustrated in the drawing with sheet e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com