In-line jet pumps and methods of use

a jet pump and jet technology, applied in the field of jet pumps, can solve the problems of heavy equipment, difficult maneuverability, and large equipment for removing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

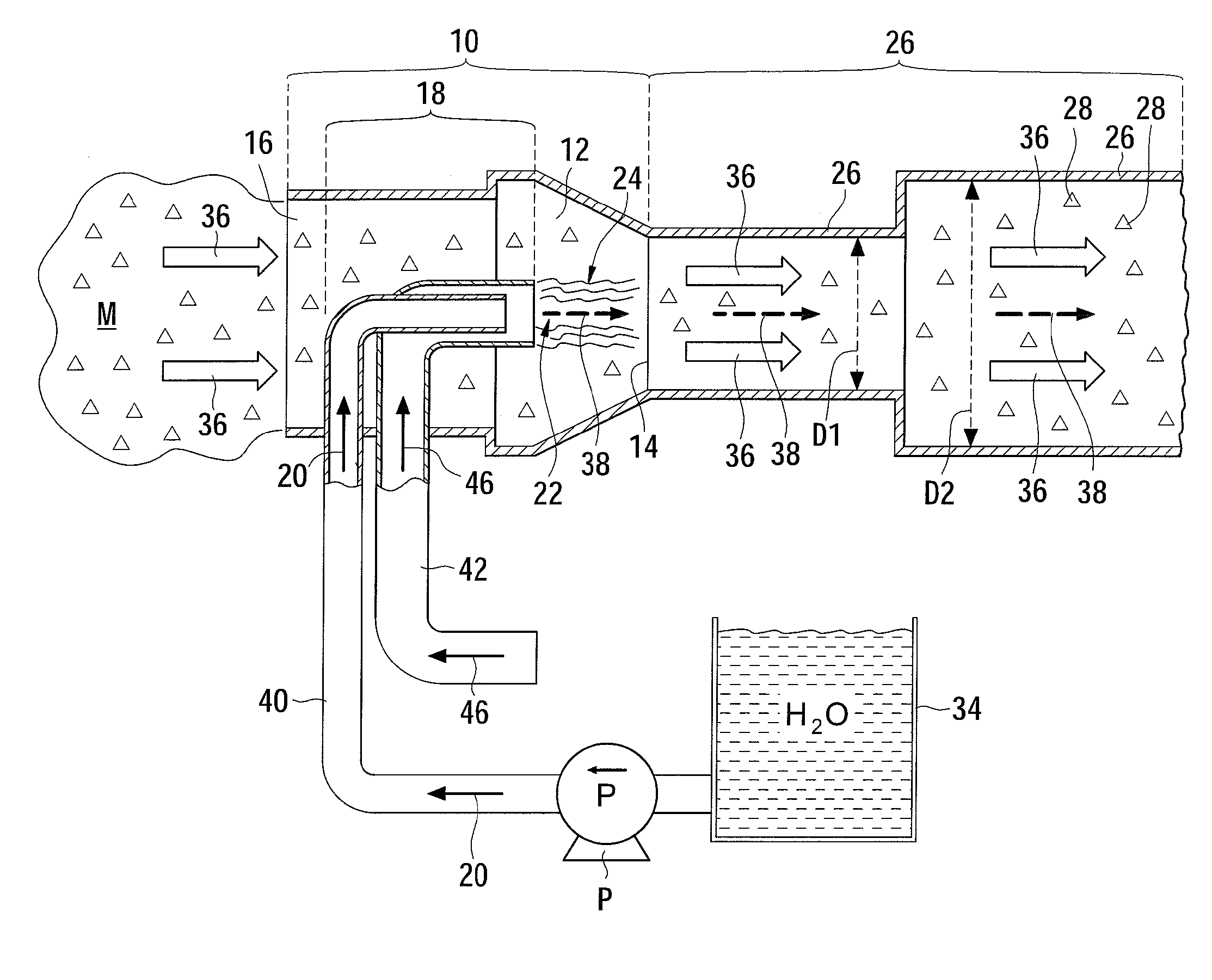

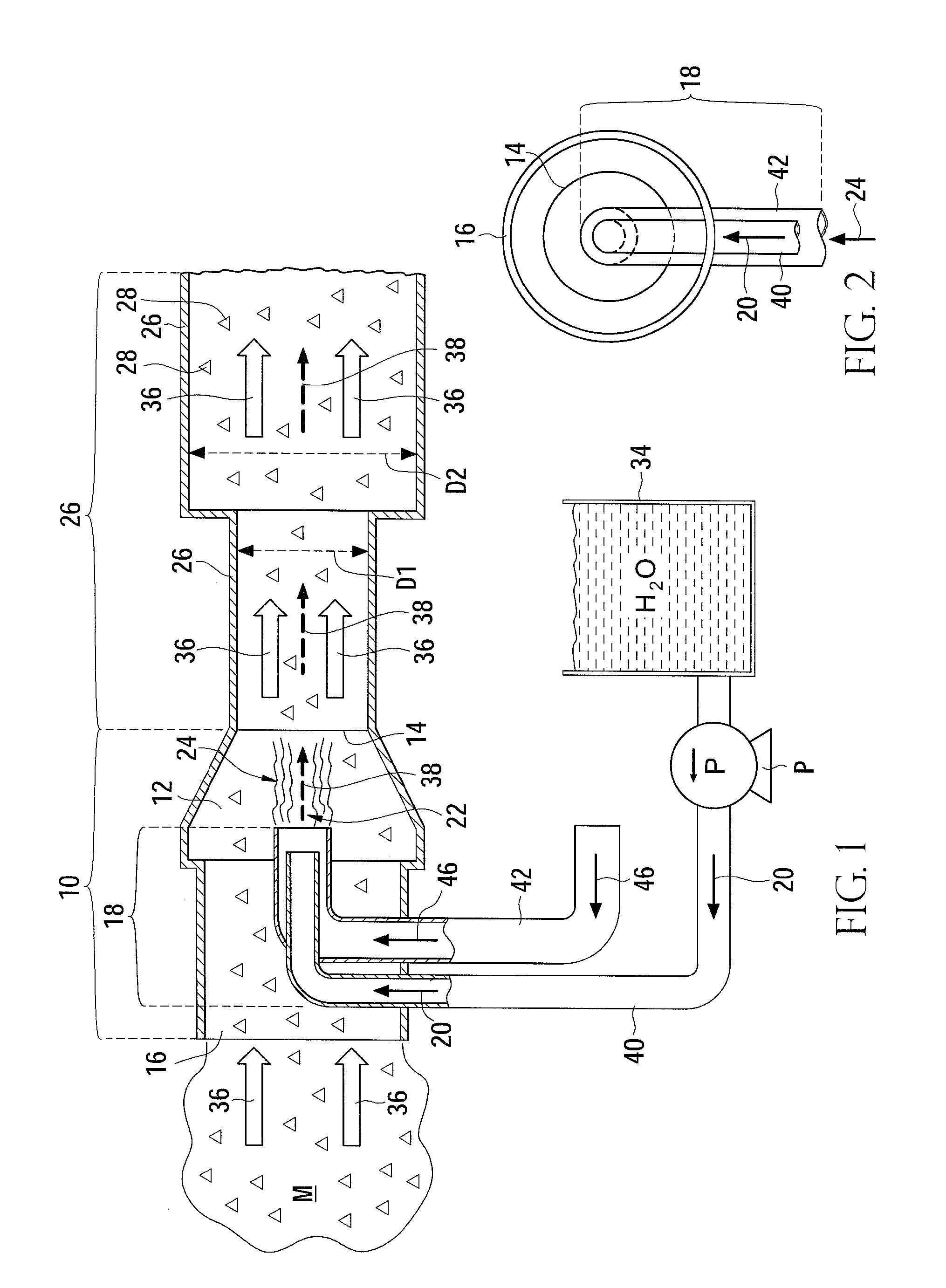

[0039]The inline jet pump was demonstrated to have superior material-moving capabilities of a rate of movement of a slurry of sand, silt and water of at least about 50 tons (4.5×104 kg) per hour when the second inner diameter of the discharge conduit was about 4 inches (10.2 cm), the first inner diameter of the discharge conduit was about 3 inches (7.6 cm), the diameter of the nozzle assembly at the point of ejection of the pressurized fluid was about 0.625 inches (1.59 cm), pressurized fluid pressure was about 150 psi (1034 kPa), and the flow rate of the pressurized fluid was about 143 gallons (541 L) per minute.

example 2

[0040]Even better performance of the inline jet pump of a rate of movement of a slurry of sand, silt and water of at least about 100 tons (9.1×104) kg) per hour was attained when the second inner diameter of the discharge conduit was about 6 inches (15.24 cm), the first inner diameter of the discharge conduit was about 4 inches (10.2 cm), the diameter of the nozzle assembly at the point of ejection of the pressurized fluid was about 0.875 inch (2.22 cm), the pressurized fluid pressure was about 150 psi (1034 kPa), and the flow rate of the pressurized fluid was about 280 gallons (1060 L) per minute.

[0041]The present invention can be used in any application requiring significant suction effect on solid material in a liquid or gaseous environment. The dimensions of the various component parts of jet pumps and systems of this invention may vary depending upon the circumstances in which the jet pump or system will be employed, so long as the dimensions permit the components to function a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com