Reservoir system and method

a reservoir and reservoir technology, applied in the field of fluid reservoirs, can solve the problems of increasing the potential for unclean and unsanitary bags, increasing the difficulty of cleaning, and health risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

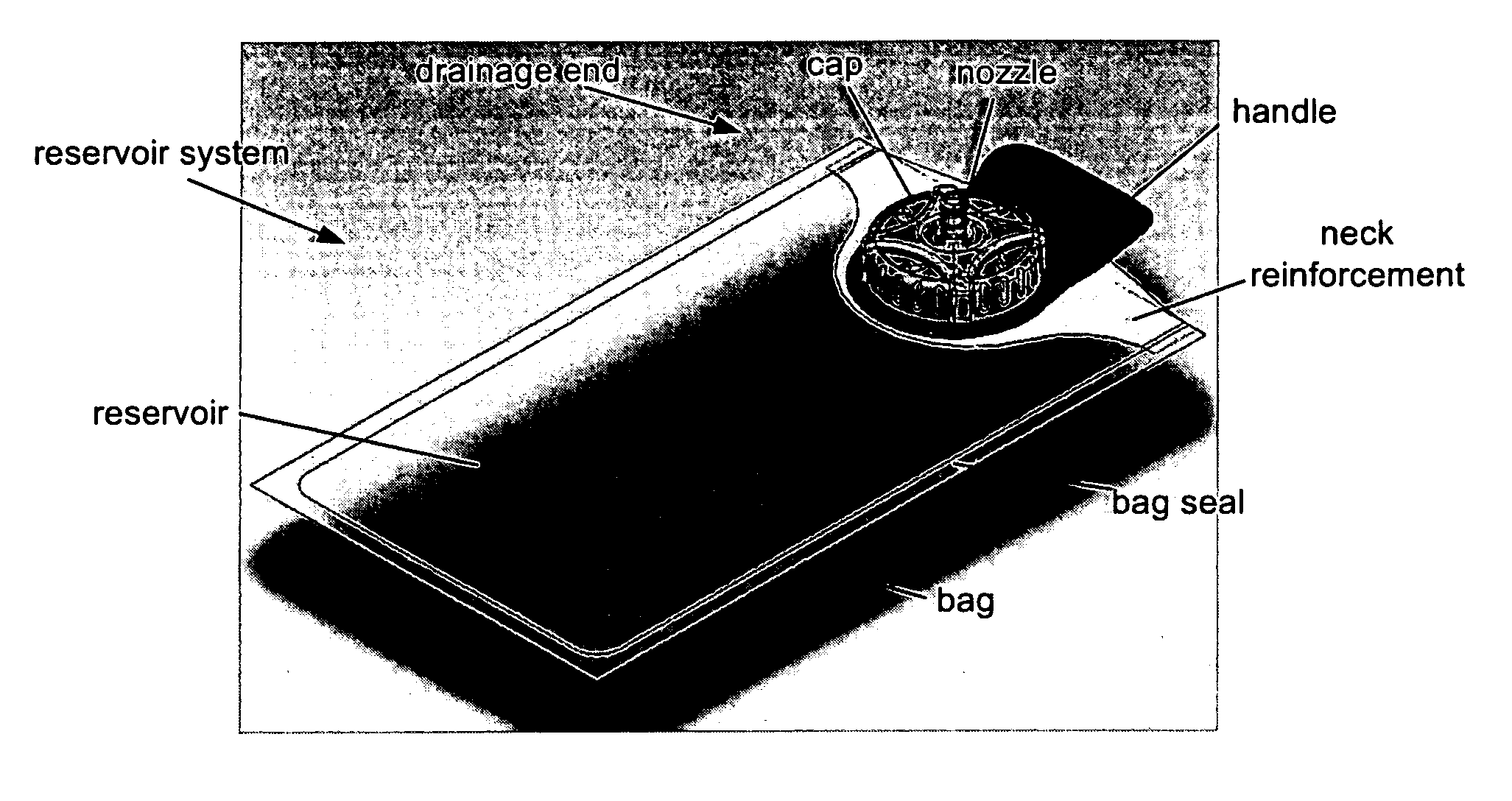

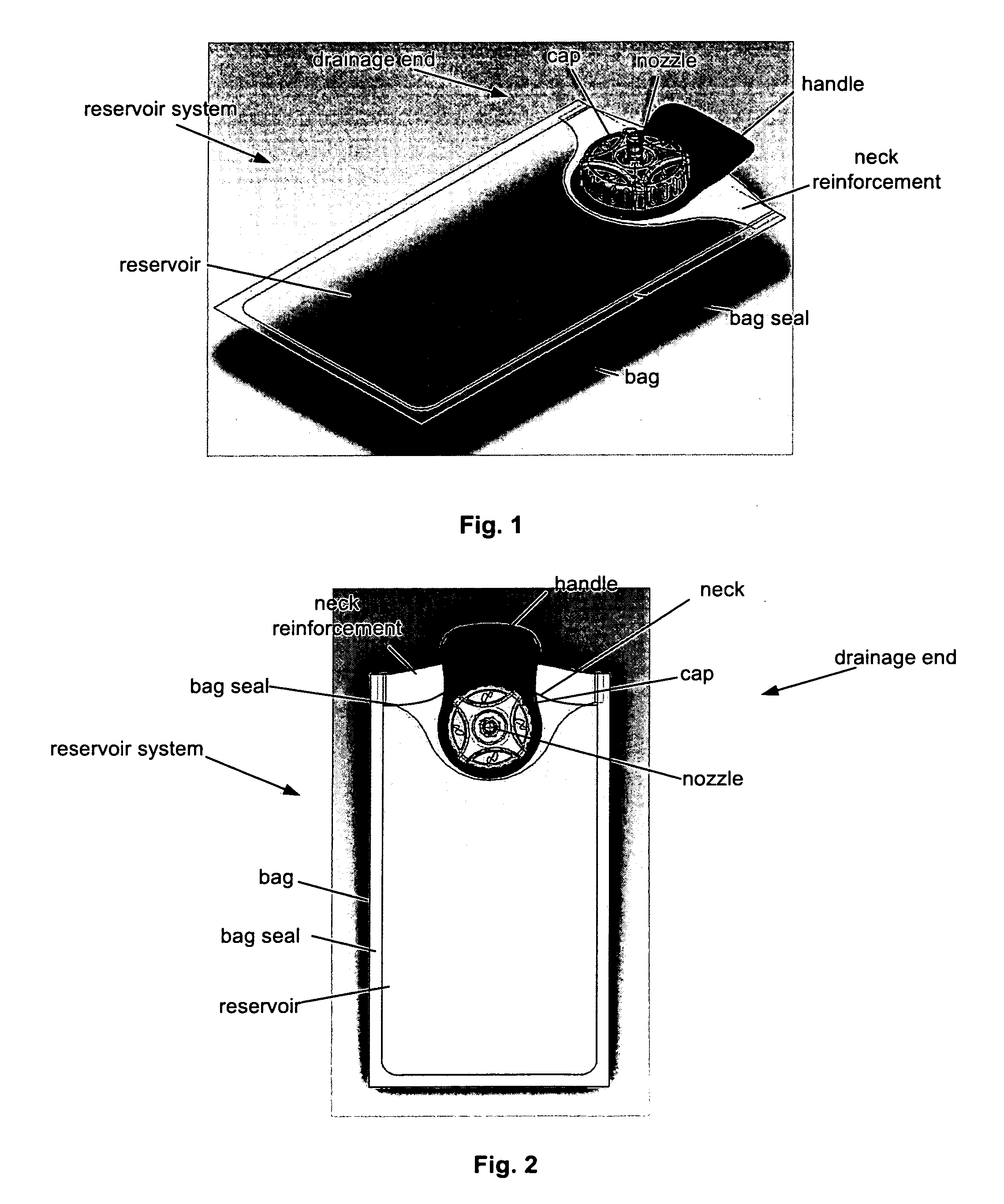

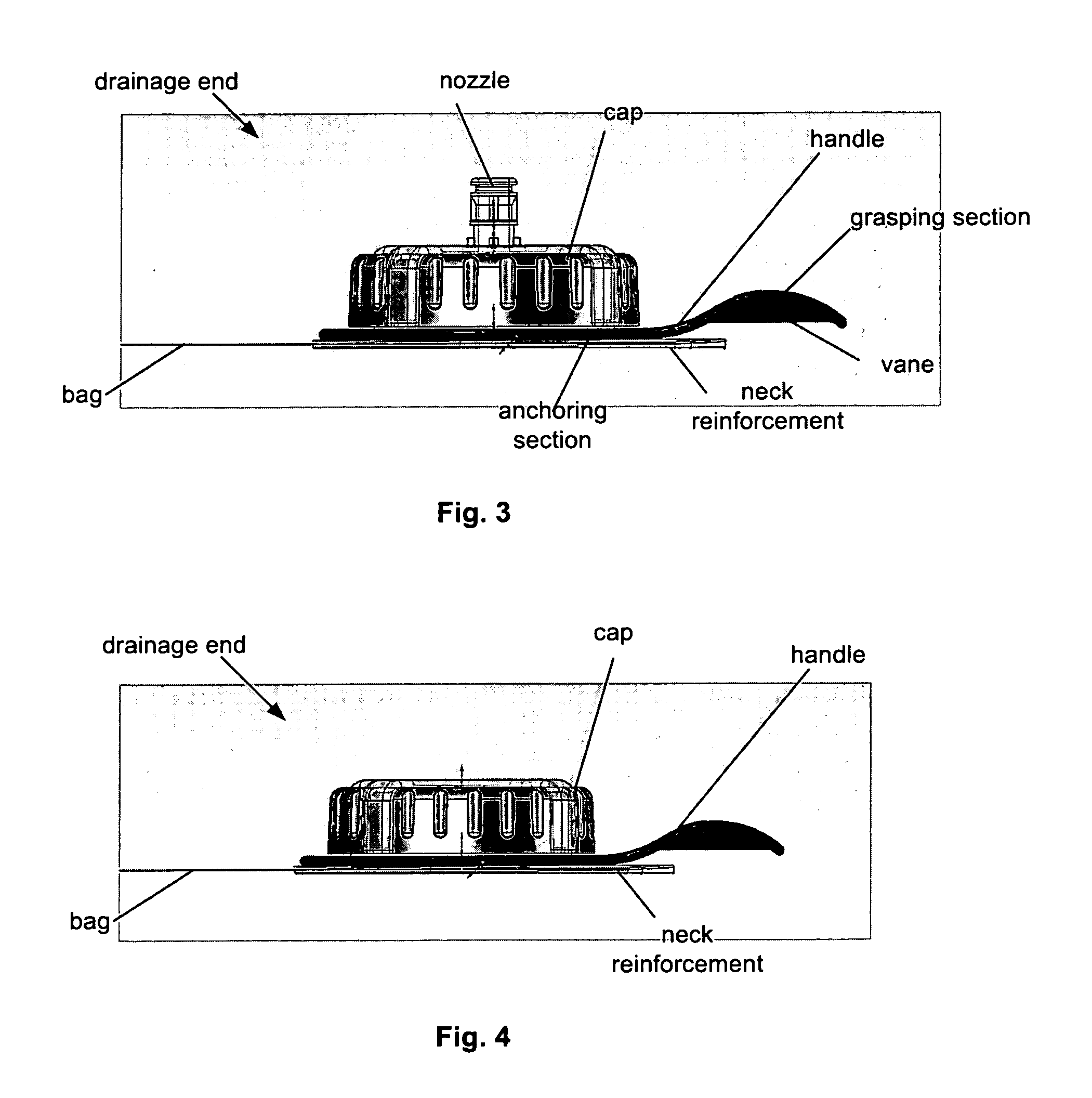

[0037]FIGS. 1 and 2 illustrate that a reservoir system can have a container, such as a bag and a sealing member, such as a removably attachable cap, for example at a drainage end of the reservoir system. The bag can have at least one hollow chamber, such as the reservoir. The reservoir can be lined with an ultra-stable material, such as a durable, resilient film. The ultra-stable material can be formed into an embossed and / or extruded laminate film (e.g., to line the reservoir). The bag can be made entirely or in part from the ultra-stable material. The bag can be spray-coated, dip-coated, static-charge coated, or otherwise coated along the surface of the reservoir with the ultra-stable material. The ultra-stable material can be a material that will minimally leech into fluids during normal operating conditions (e.g., temperatures below about 180° F.). The ultra-stable material can be polyethylene, antimicrobial materials, such as silver ion (e.g., AgION from AgION Technologies, Inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com