Gymnastic machine

a gymnastic machine and body technology, applied in the field of gymnastic machines, can solve the problems of high cost, negative impact on production costs, and complex bill of materials of gymnastic machines,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

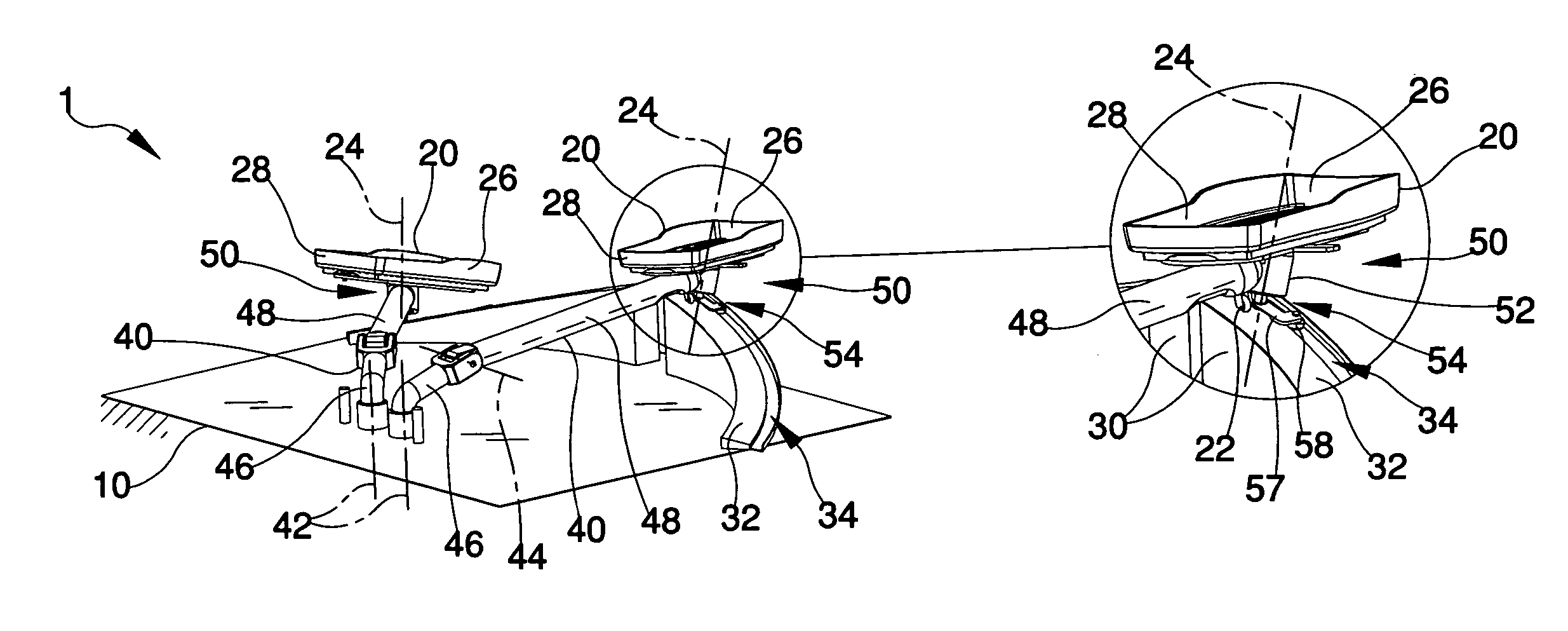

[0016] In FIG. 1, number 1 indicates, in its entirety, a gymnastic machine for performing skating training exercises. The machine 1 comprises a frame 10 and a pair of footrests 20, each of which is connected to the frame 10 according to an open chain kinematic model by means of at least an arm 40, to which it is connected in an end position. Each arm 40 is carried by the frame 10 in a rotatable manner with respect to a first substantially vertical pivot axis 42 and is articulated on the side of the first axis 42 about a second pivot axis 44 substantially transverse to the first axis 42, and thus horizontal. In particular, each arm 40 comprises a first lever 46 hinged to the frame 10 at the first axis 42 and a second lever 48 hinged to the first lever 46 at the second axis 44, which carries a respective footrest 20 in an end position. The open kinematic chain corresponding to each footrest 20 and comprising the respective articulated arm 40 is closed by a shaped element 30 to give st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com