Method for Internal High-Pressure Deformation of a Blank

a high-pressure deformation and blank technology, applied in the direction of manufacturing tools, metal-working apparatus, shaping tools, etc., can solve the problems of residual fluid remaining, adverse effect of subsequent deformation process, residual fluid collecting in the receiving space, etc., and achieves low viscosity lubricant and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

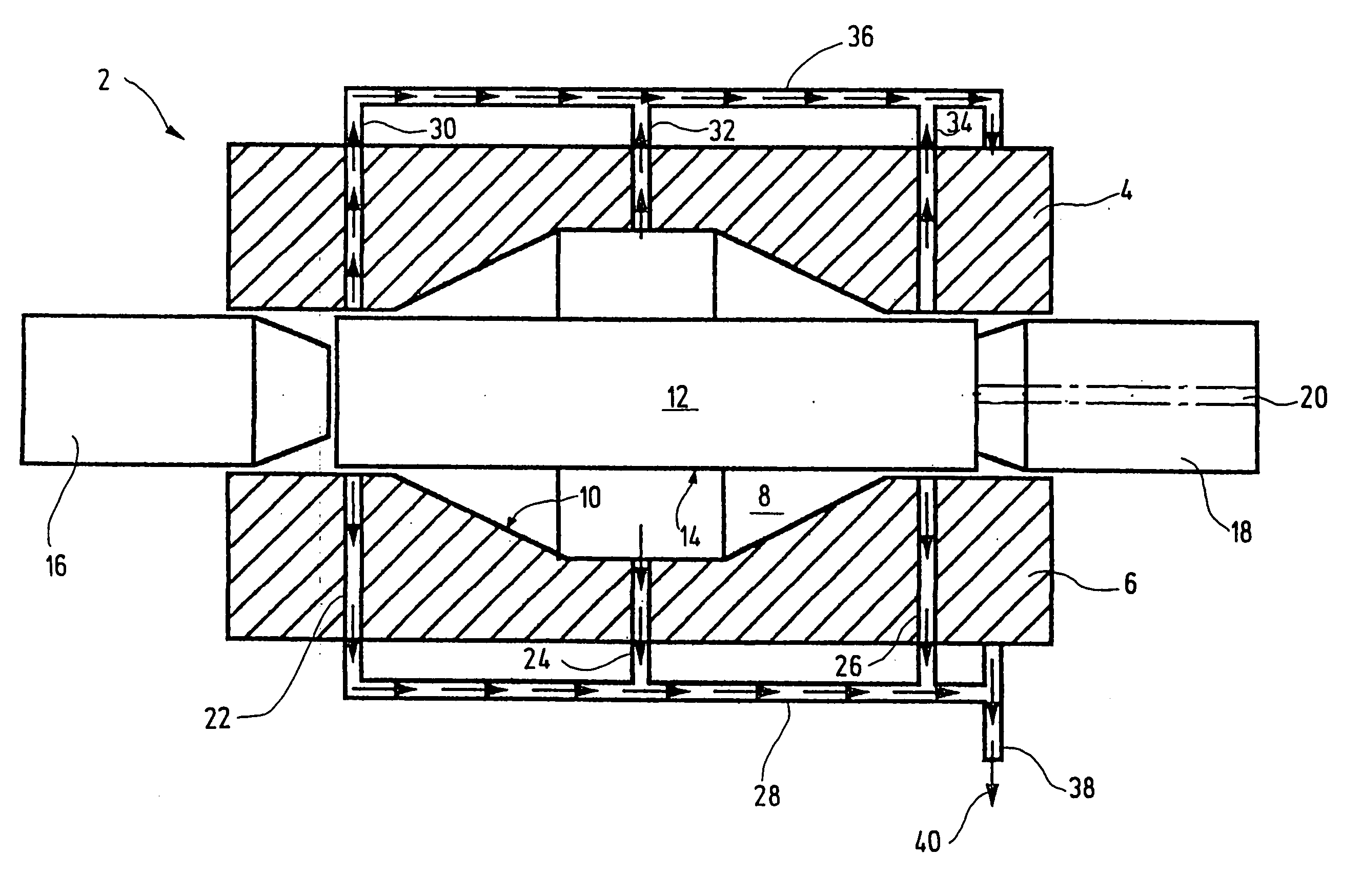

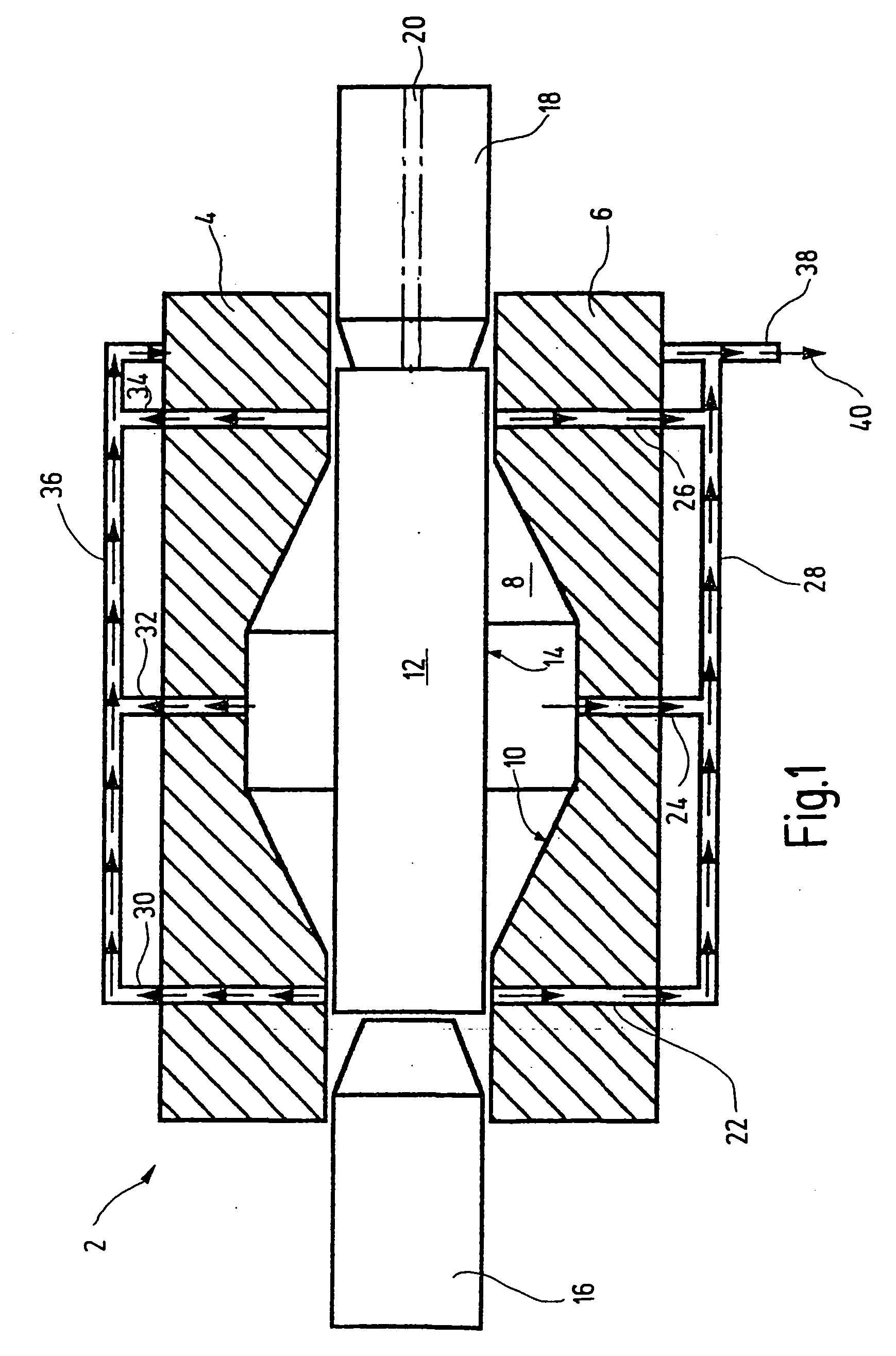

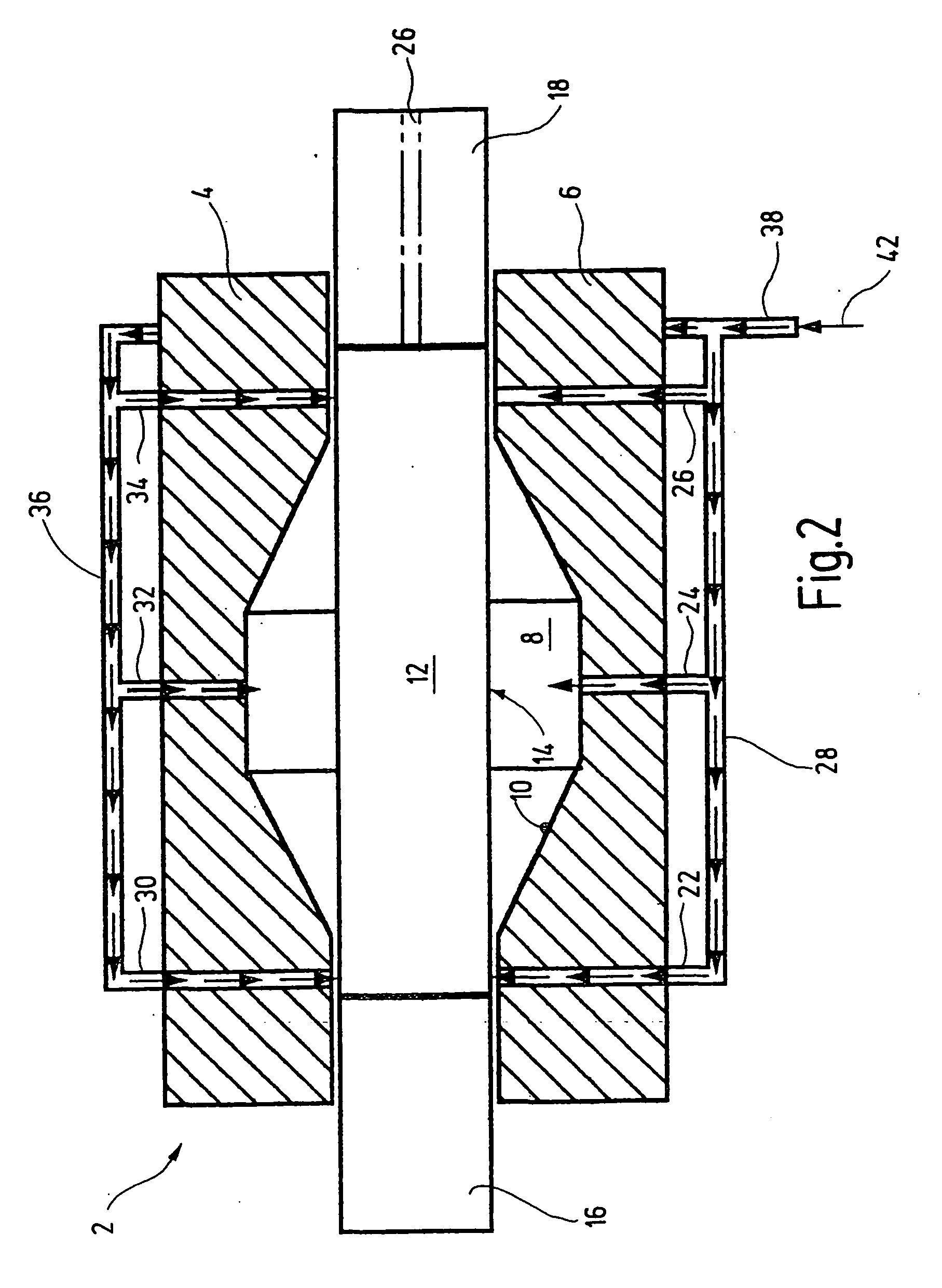

[0023] The apparatus, which is denoted overall by reference numeral 2 in FIG. 1, has an upper die half 4 and a lower die half 6. The die halves 4 and 6 delimit a receiving space 8, the wall 10 of which corresponds to the external geometry of a shaped part which is to be produced.

[0024] An as yet undeformed, tubular blank 12 has been inserted into the receiving space 8, the outer skin 14 of which blank 12 comes to bear against the wall 10 of the receiving space 8 during the deformation process. The blank 12 may be laterally sealed with the aid of axial cylinders 16 and 18, the axial cylinder 18 having a line 20 for a high-pressure fluid supply (not shown). High-pressure fluid can be introduced into the cavity of the blank 12 through the line 20, so that the blank 12 can be deformed.

[0025] The lower die half 6 has three passages 22, 24 and 26 opening out in the receiving space 10. These passages are connected to a manifold 28. Accordingly, the upper die half 4 has passages 30, 32 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Deformation enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com