Web inspection and repair machine with retractable inspection zone

a technology of inspection zone and inspection machine, which is applied in the direction of manual label dispensers, lamination, cutting/splicing processed materials, etc., can solve the problems of reducing the work efficiency of the machine designer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

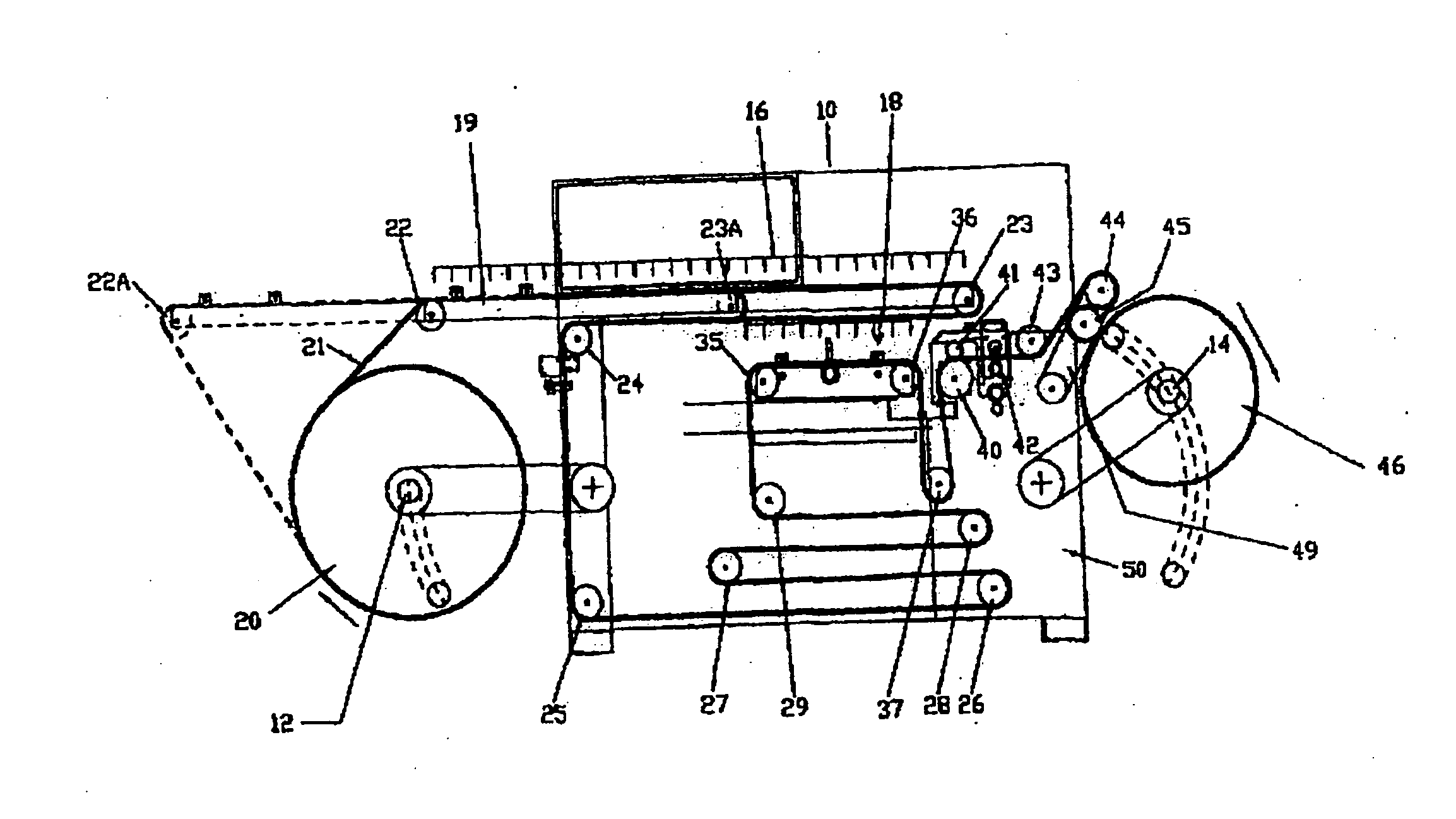

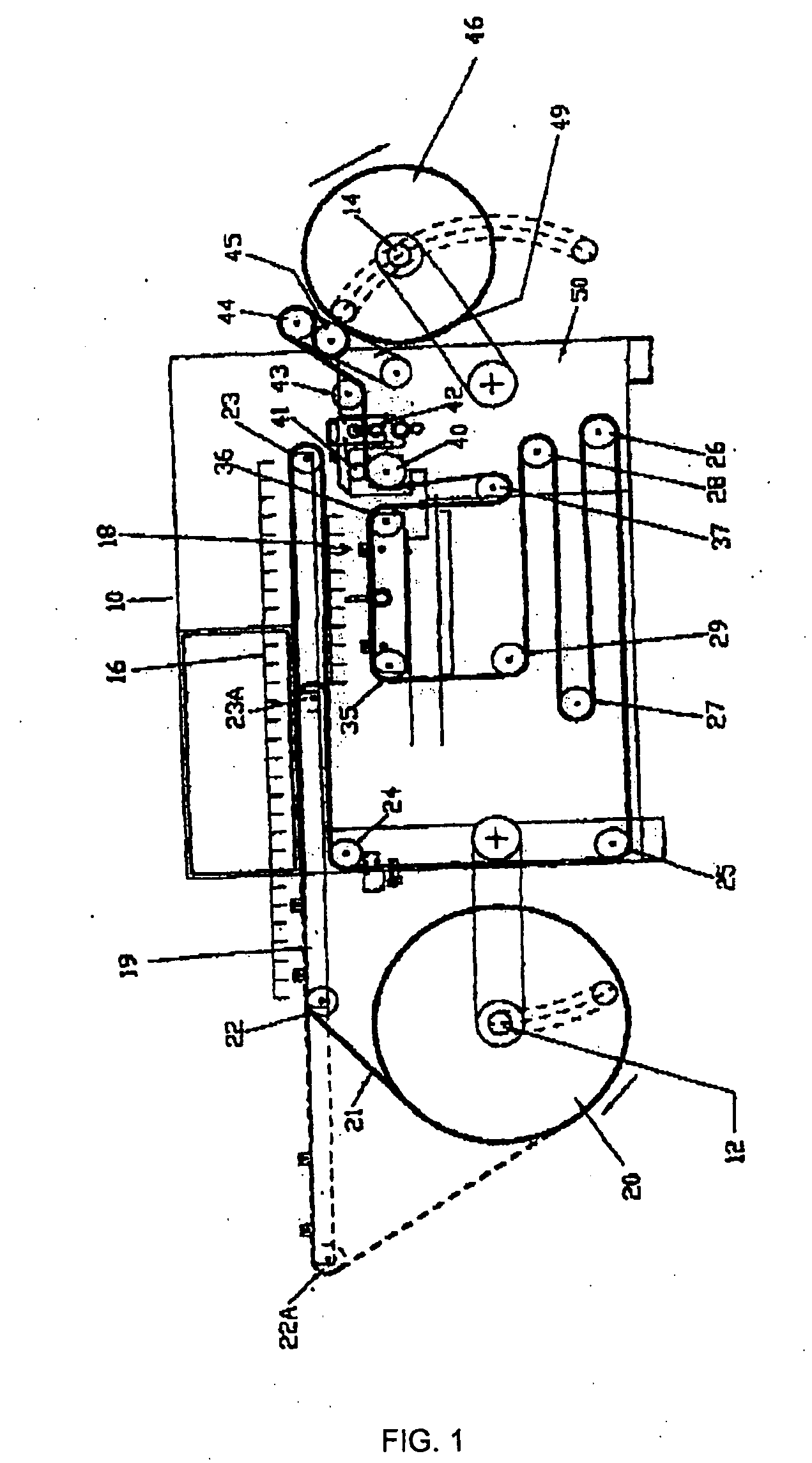

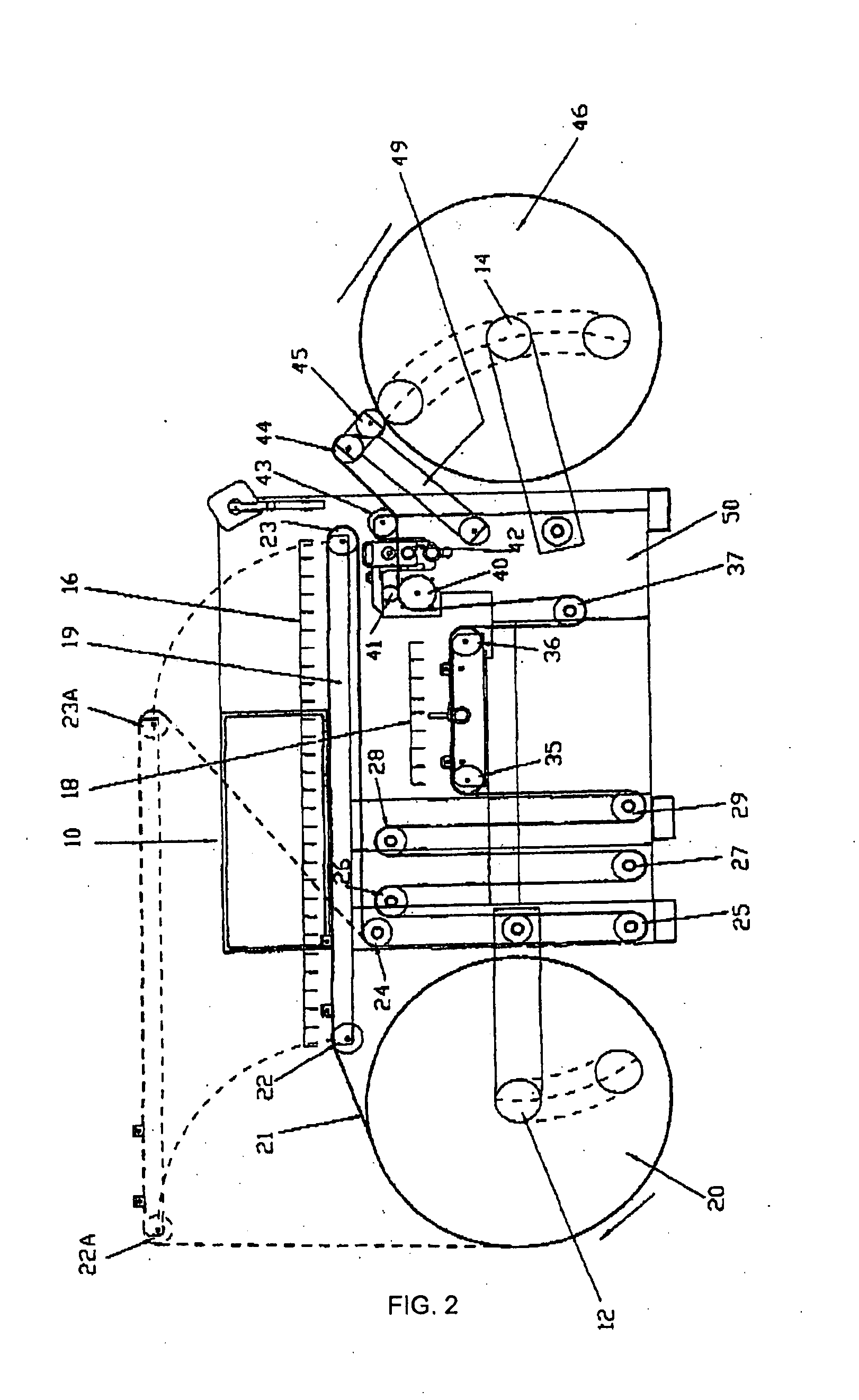

[0045] Attention is first directed to FIG. 1, which is a schematic side-elevational view showing the major components of a web processing mechanism to which the present invention has been applied.

[0046] The mechanism shown generally at 10 in FIG. 1 includes an unwind mandrel 12, a rewind mandrel 14, an inspection zone 16, and a splicing area 18.

[0047] A coil 20 of web material is mounted on the unwind mandrel 12, with the web 21 being paid off the coil 20. The web 21 is next threaded sequentially around rollers 22 and 23. The inspection zone 16 extends generally between rollers 22 and 23. Rollers 22 and 23 are mounted into an inspection zone support structure 19, which is movable between a first forward position (solid outline; FIG. 3) and a second rearward “retracted” position (dotted outline; FIG. 4).

[0048] The web 21 exiting the inspection zone support structure is sequentially entrained around fixed idler rolls 24, 25, 26, 27, 28 and 29. Web 21 is then entrained around idler ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com