Pinching seal for airtight containers

a technology for airtight containers and seals, which is applied in the field of compacts with tight seals, can solve the problems of not only a relatively significant force to close, but also a significant force to close and open the compact, and achieve the effect of reducing the opening force, reducing the diametrical interference, and eliminating the diametrical interference instantaneously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1 (figs.1a and 1b)

Example 1 (FIGS. 1a and 1b)

[0027] The container 1 of this example is a refill for a cosmetic product including a dish 20 and a cover 10. The dish has a base 21 and a lateral wall 22. The cover 10 is equipped with a seal 30 that forms a closed contour at the periphery of the cover.

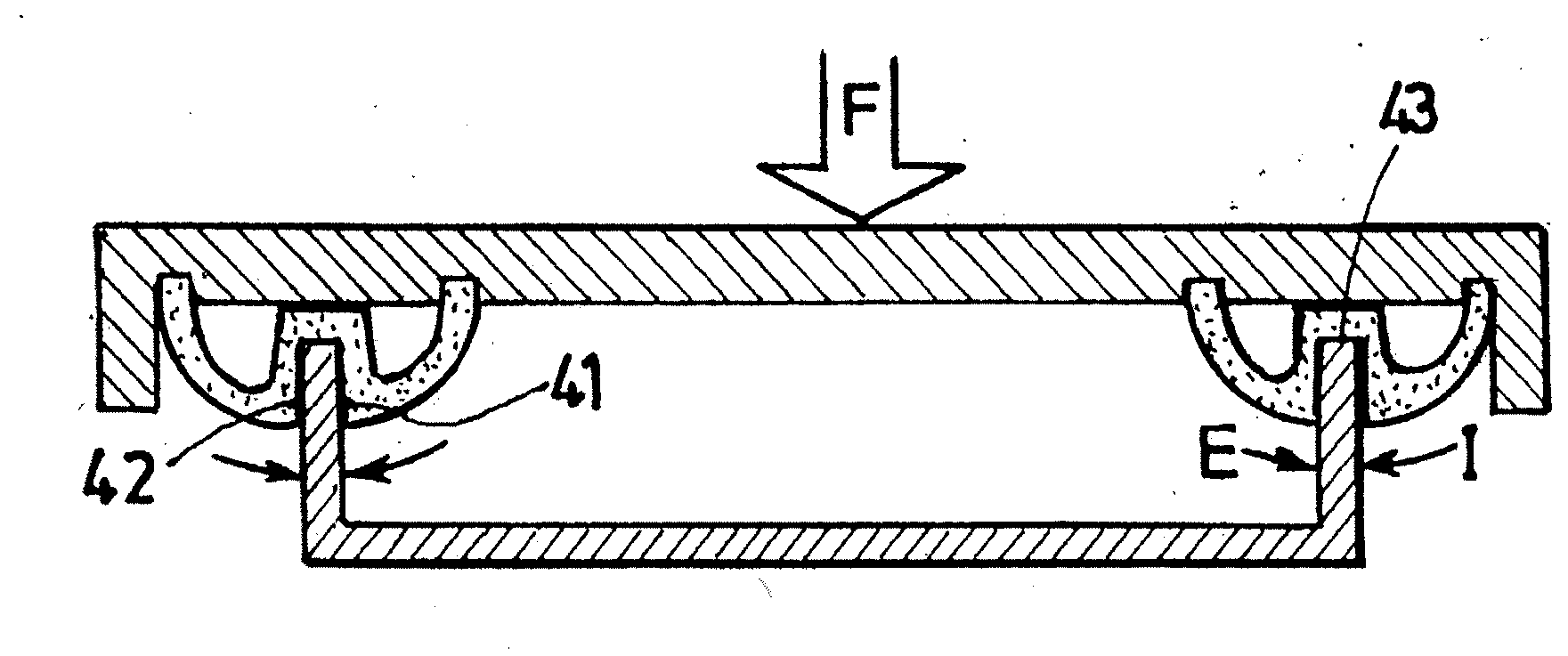

[0028] The seal 30 includes a substantially axial internal lip 31 and a substantially axial external lip 32 that together surround a recess 33 intended to receive the upper edge 23 of the lateral wall 22 of the dish 20. The seal 30 is designed so that when the upper edge 23 of the lateral wall 22 of the dish comes into contact with the base 330 of the recess 33 by transmitting axial closing force F on the seal, the ends of the internal 310 lips and external 320 lips are subjected, respectively, to a centrifugal (E) and centripetal (I) lateral movement so that both come into contact with the lateral wall 22 of the dish 20.

[0029] The seal 30 is made of a material suitable for the type of cosmetic product pa...

example 2 (fig.2)

Example 2 (FIG. 2)

[0032] The container of this example is a refill for a cosmetic product similar to that presented in the previous example, except that the seal is in the form of a molded elastomeric part that includes, in addition to the internal lips 31 and external lips 32, a central portion 34, and therefore entirely covers the cover 10. The cover 10 may, in this case, be made of any material, since the air-diffusion barrier is provided entirely by the seal and the dish, which must therefore be made of a material creating a suitable diffusion barrier.

example 3 (

FIGS. 3a and 3b)

[0033] The cover of the container of this example has a seal of which the cross-section has a low average thickness with respect to the height of the substantially axial lips, in this case typically less than one-fifth of the height. The ends of the internal and external lips have, on their opposing surfaces, gadroons 310′ and 320′, of which the smaller radius of curvature makes it possible to more precisely localize the contact areas 41′, 42′, to reduce the contact surface and to locally increase the normal stress in these areas. If, due to a lack of planarity, the contact is not established in 43′, there are at least two airtight contact areas in 41′ and 42′.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com