Rebar chair with depth gauge

a technology of depth gauge and rebar chair, which is applied in the field of rebar chair with depth gauge, combined rebar chair and depth gauge, which can solve the problem of not providing any means to ensure the minimum required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

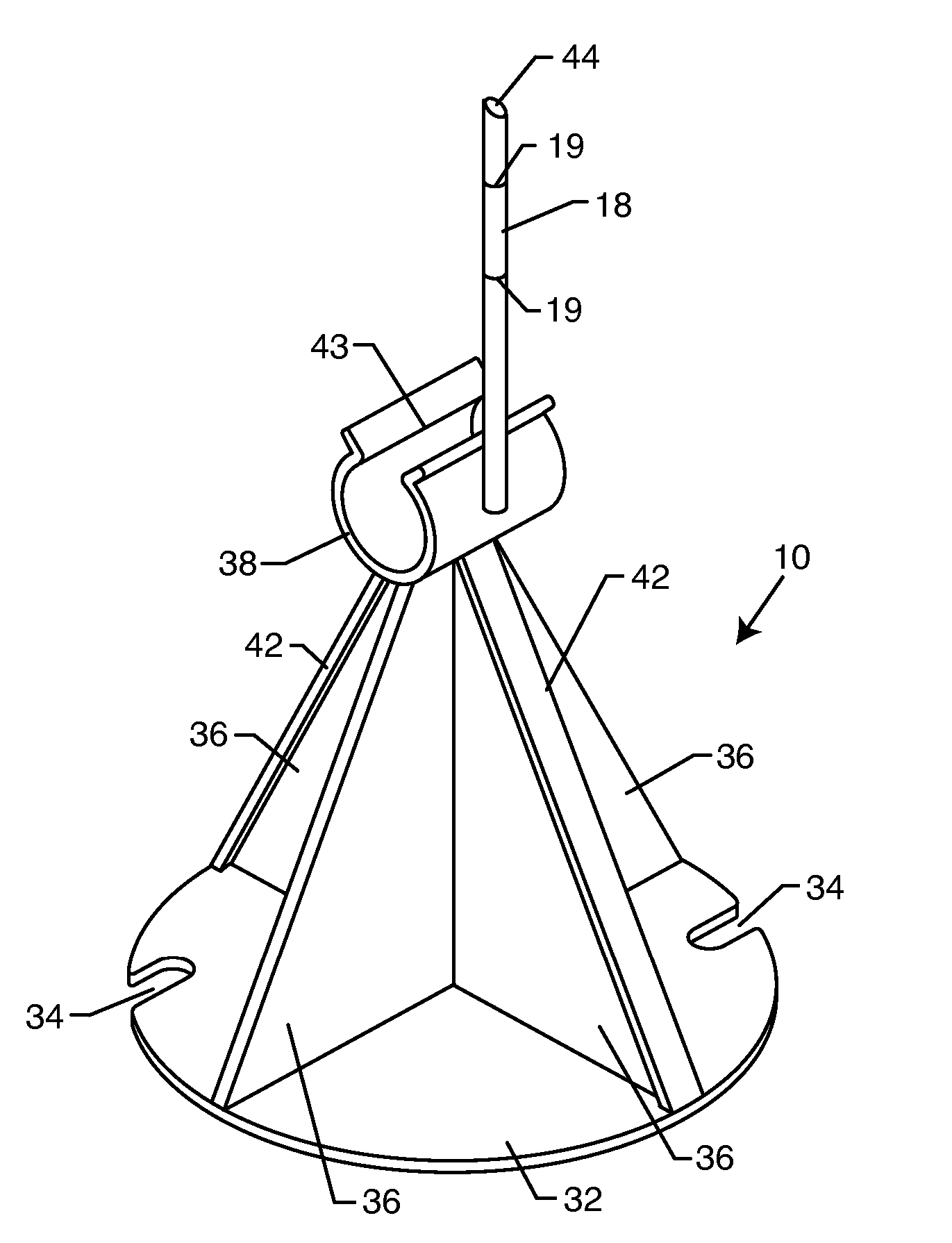

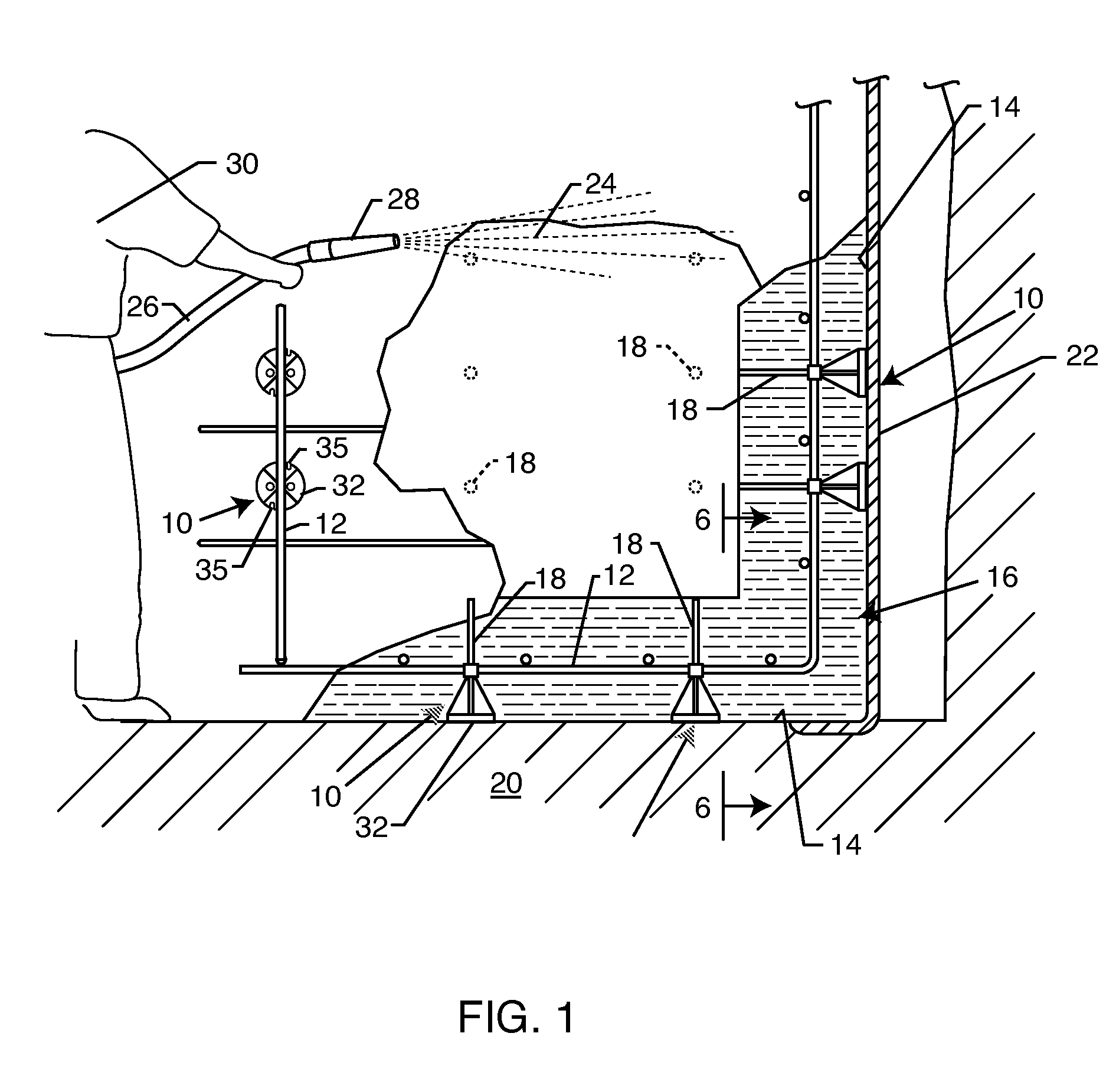

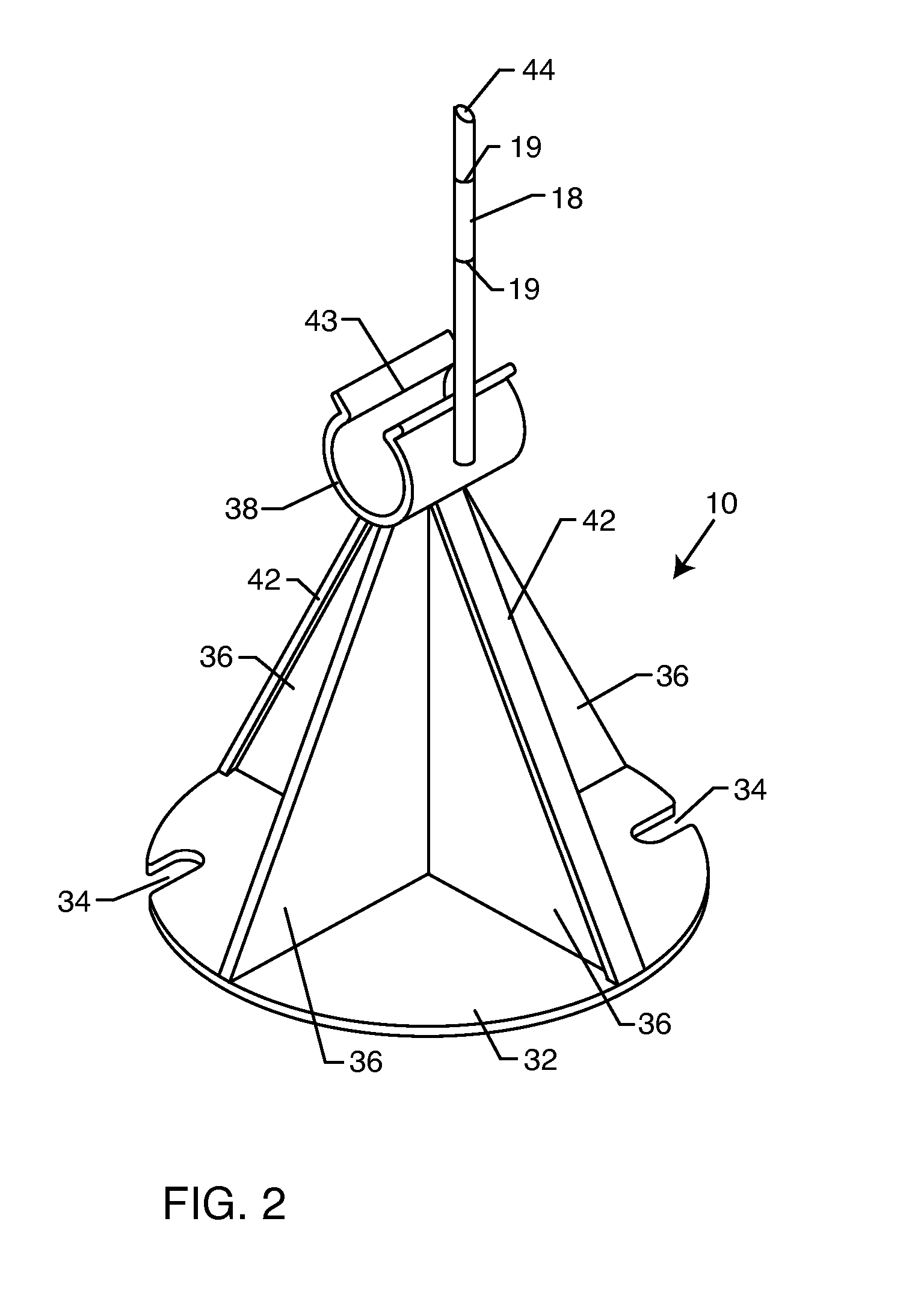

[0019] As shown in the exemplary drawings, an improved rebar chair referred to generally by the reference numeral 10 in FIG. 1 is provided for supporting a grid or cage 12 of reinforcing steel (rebar) in a predetermined position within an open-sided mold or form 14 of the type used, e.g., for constructing a concrete shell structure 16 for a swimming pool or spa or the like. The rebar chair 10 supports the reinforcing steel with a predetermined minimum spacing from a closed side of the form 14, thereby assuring a predetermined minimum concrete wall thickness between the steel and an outboard side of the concrete shell structure 16. In addition, and in accordance with a primary feature of the invention, the rebar chair 10 further includes a rod-shaped depth gauge 18 for assuring a predetermined minimum concrete wall thickness between the steel and an inboard side of the concrete shell structure 16.

[0020]FIG. 1 generally depicts the open-sided mold or form 14 of a type commonly used i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com