Product display hanger

a product display and hanging rod technology, applied in the field of laminated products, can solve the problems of product falling off the grips of the alligator clip, product not liking the horizontal mounting rods to display products, and the vendor cannot have shelf or peg space, so as to facilitate product spacing and alignment, and minimize the risk of having the weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

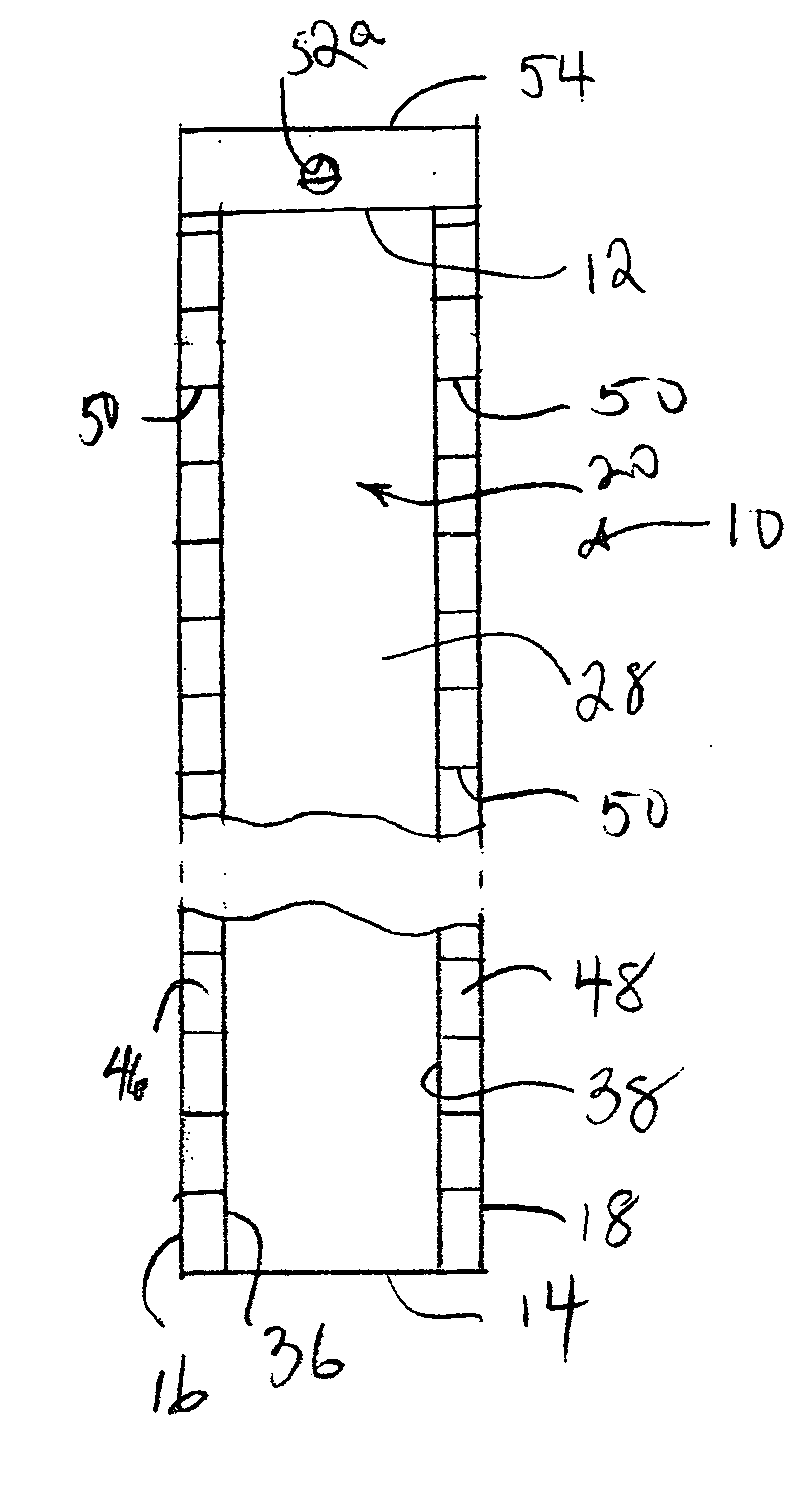

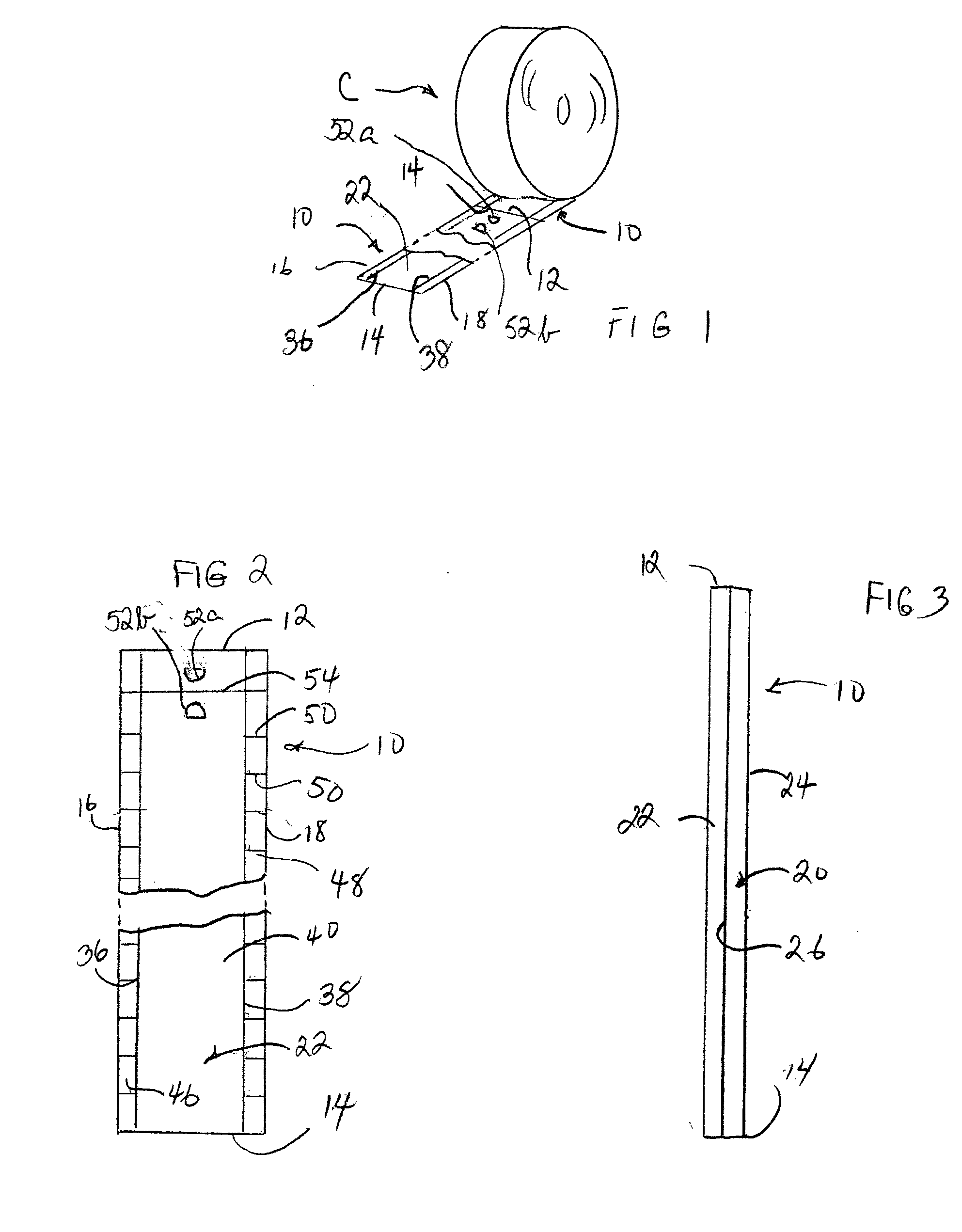

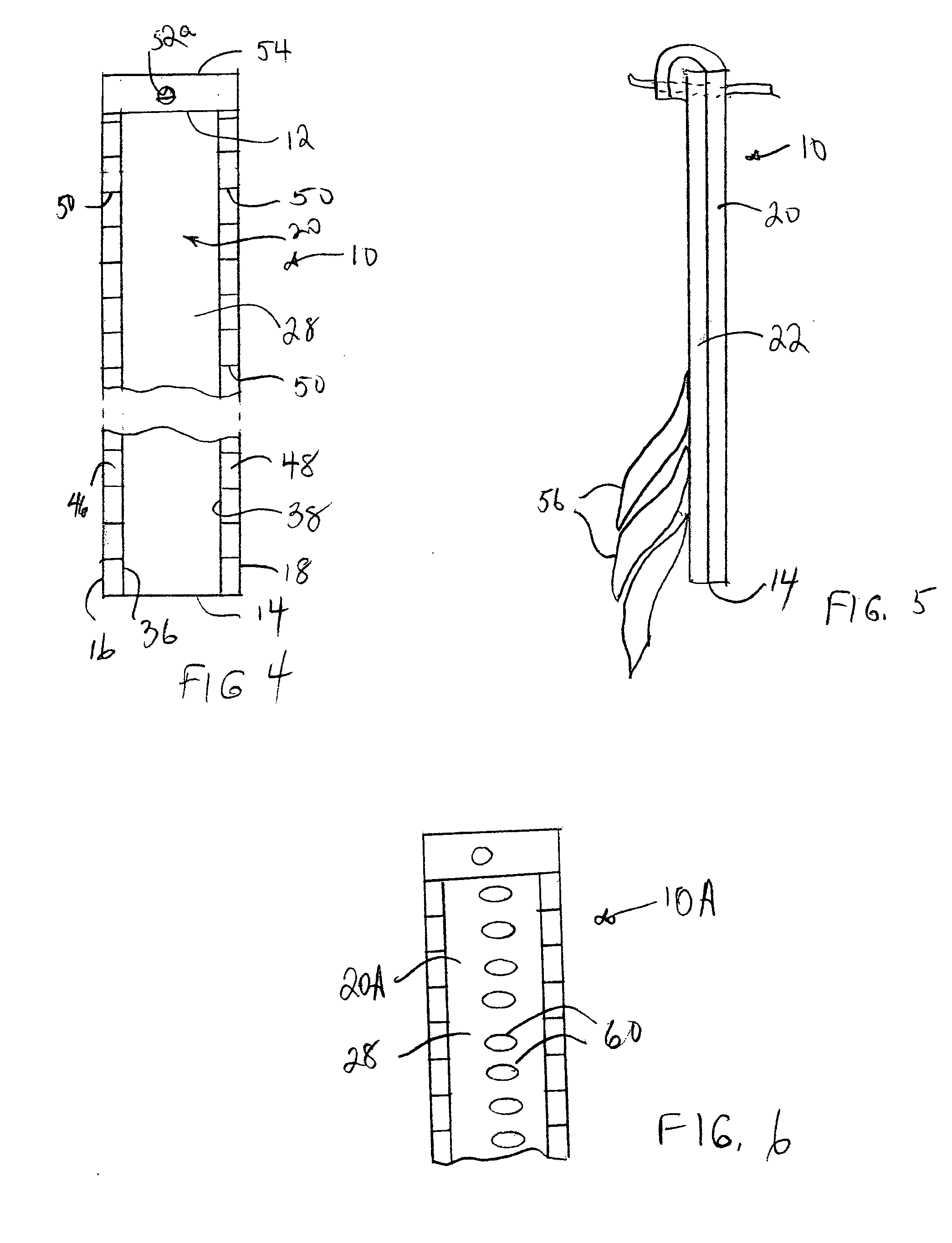

[0029] A product display hanger in accordance with the invention is identified generally by the numeral 10 in FIGS. 1-5. The product display hanger 10 is an elongate laminated tape with first and second longitudinal ends 12 and 14 and first and second side edges 16 and 18. A plurality of the product display hangers 10 are connected in end-to-end relationship and can be wound into a tight coil C, as shown in FIG. 1 for dispensing from a tape type dispenser. More particularly, the first end 12 of one product display hanger 10 is joined unitarily to the second end 14 of an adjacent product display hanger 10. Perforations extend between the adjacent product display hangers 10 so that the display hangers 10 can be separated sequentially from one another, or used in tandem. The perforation for the continuity of product display hangers 10 on a roll or coil is created to allow for separation into individual product display hangers for continuity and strength so as to be used in sections of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com