Lubricating Oil Composition

a technology of lubricating oil and composition, which is applied in the direction of lubricant composition, liquid carbonaceous fuel, fuel, etc., can solve the problems of increasing fuel consumption, reducing the life of the filter, and raising the back pressure of the vehicle engine, so as to reduce the clogging of diesel particulates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Formulations

[0108] Table 1 indicates the formulations that were tested.

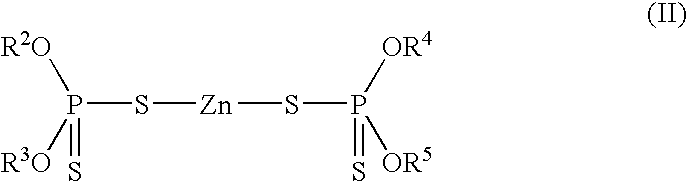

[0109] The formulations in Table 1 comprised conventional antioxidants, anti-foams, dispersants, friction modifiers, seals fix additives, pour point depressants, viscosity index modifiers and zinc dithiophosphate additives.

[0110] The magnesium detergent used was that available under the trade designation “Infineum C9012” (TBN 345 mg.KOH / g) from Infineum.

[0111] The calcium detergents used were those available under the trade designations “Infineum M7101” (TBN 168 mg.KOH / g), “Infineum M7102” (TBN 64 mg.KOH / g) and “Infineum M7105” (TBN 280 mg.KOH / g) from Infineum.

[0112] The base oils used in said formulations were Group III base oils available from the Shell group under the trade designations “XHVI-5.2” and “XHVI-8.2”.

[0113] All formulations described in Table 1 were SAE 5W30 viscosity grade oils.

TABLE 1Comp.Comp.Additive (wt. %)Ex. 1Ex. 2Ex. 1Ex. 2Anti-foam30 ppm30 ppm30 ppm30 ppmCalcium salicylate1——0.801...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com