Low energy electric air cycle with portal shroud cabin air compressor

a low-energy, air-cycle technology, applied in the direction of energy-efficient board measures, domestic cooling devices, lighting and heating devices, etc., can solve the problems of air cycle machines, large number of components in a typical environmental control system, and large amount of energy to opera

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following detailed description of the invention is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any theory presented in the preceding background of the invention or the following detailed description of the invention.

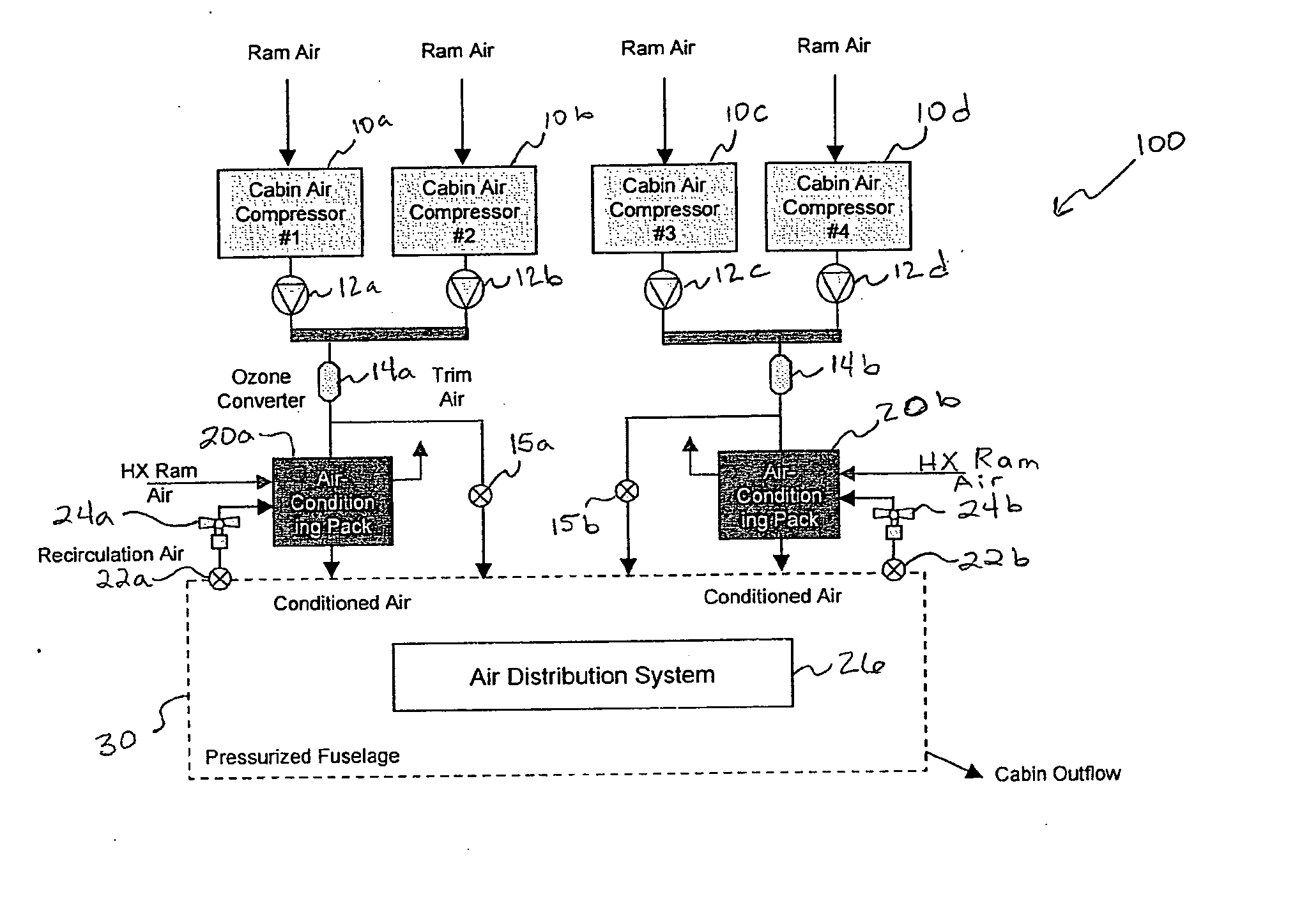

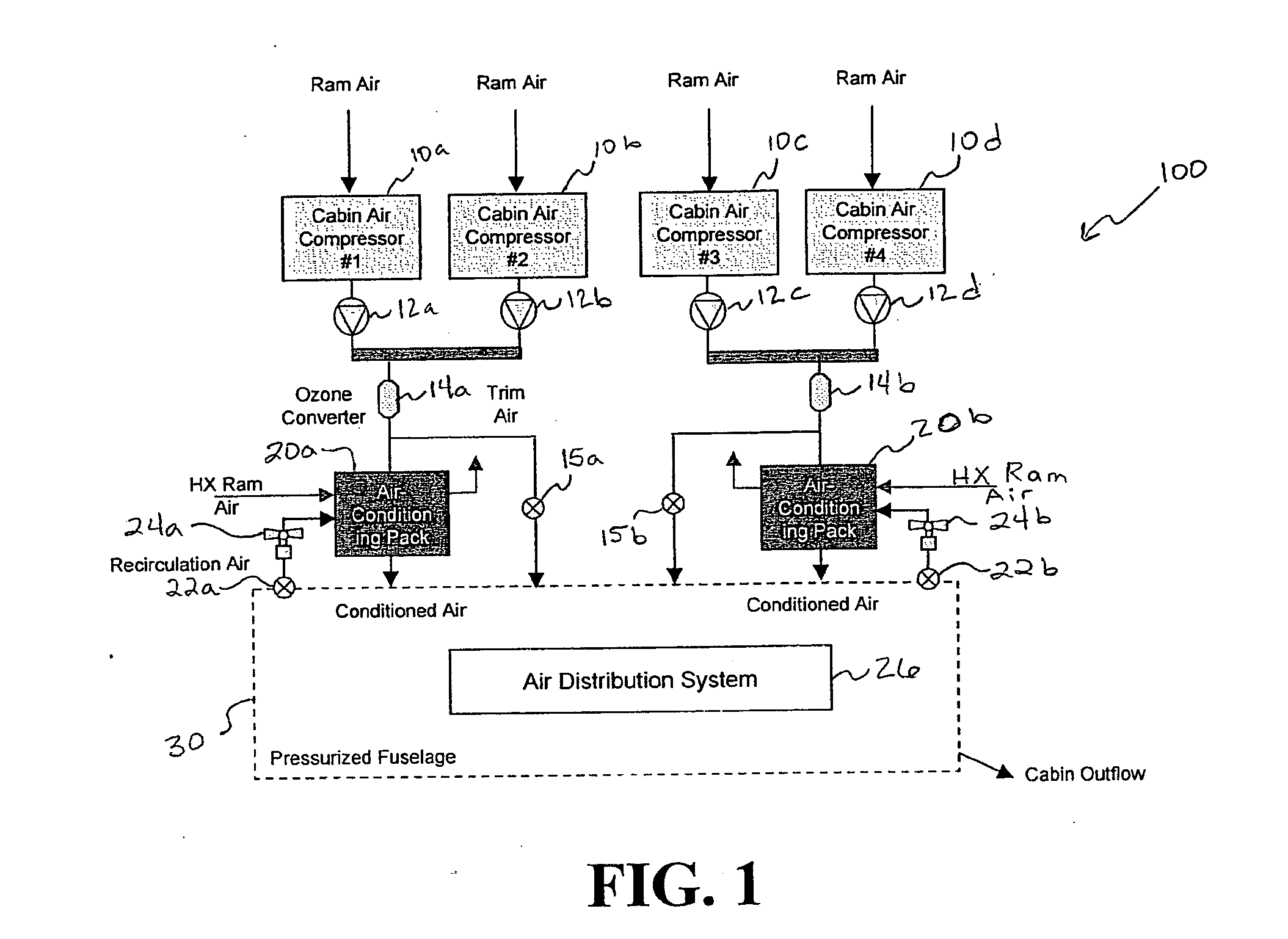

[0013] Turning now to the figures, FIG. 1 is a flow chart illustrating the top-level architecture of an exemplary environmental control system 100 for an aircrew cabin or other area in an aircraft fuselage 30. The illustrated system 100 includes four electrically-driven cabin air compressors 10a-10d, each receiving fresh ram air from inlets that are located in at least one favorable position near the aircraft's forward belly fairing leading edge. Although there are four compressors 10a-10d in the illustrated embodiment, a system that incorporates fewer compressors may still be used without departing from the scope of the present invention....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com