Control of distributed printing with multiple printers

a technology of distributed printing and printers, applied in the direction of digital output to print units, instruments, visual presentations, etc., can solve the problem of shortening the total time required for printing, and achieve the effect of good operation and favorable resulting prints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

A. First Embodiment

[0108] A1. General Hardware Structure

[0109] A2. Distributed Printing Process

[0110] A3. Virtual Printer Driver

[0111] A4. User Interface

[0112] A5. Computer Programs

[0113] A6. Effects of Embodiment

B. Second Embodiment

[0114] B1. User Interface

[0115] B2. Computer Programs

[0116] B3.Effects of Embodiment

C. Third Embodiment

[0117] C1. Distributed Printing Process

[0118] C2. Computer Programs

[0119] C3. Effects of Embodiment

A1. General Hardware Structure

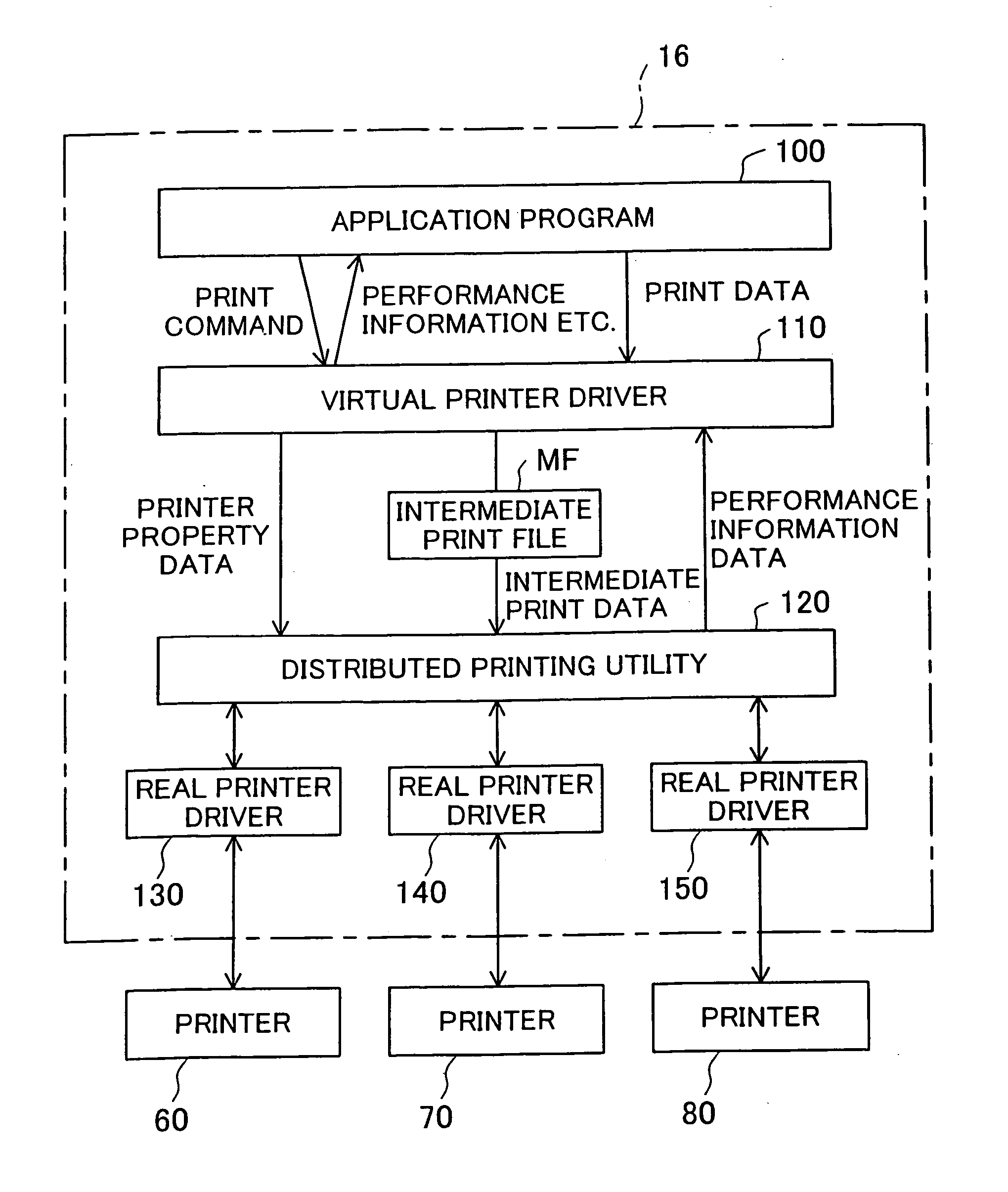

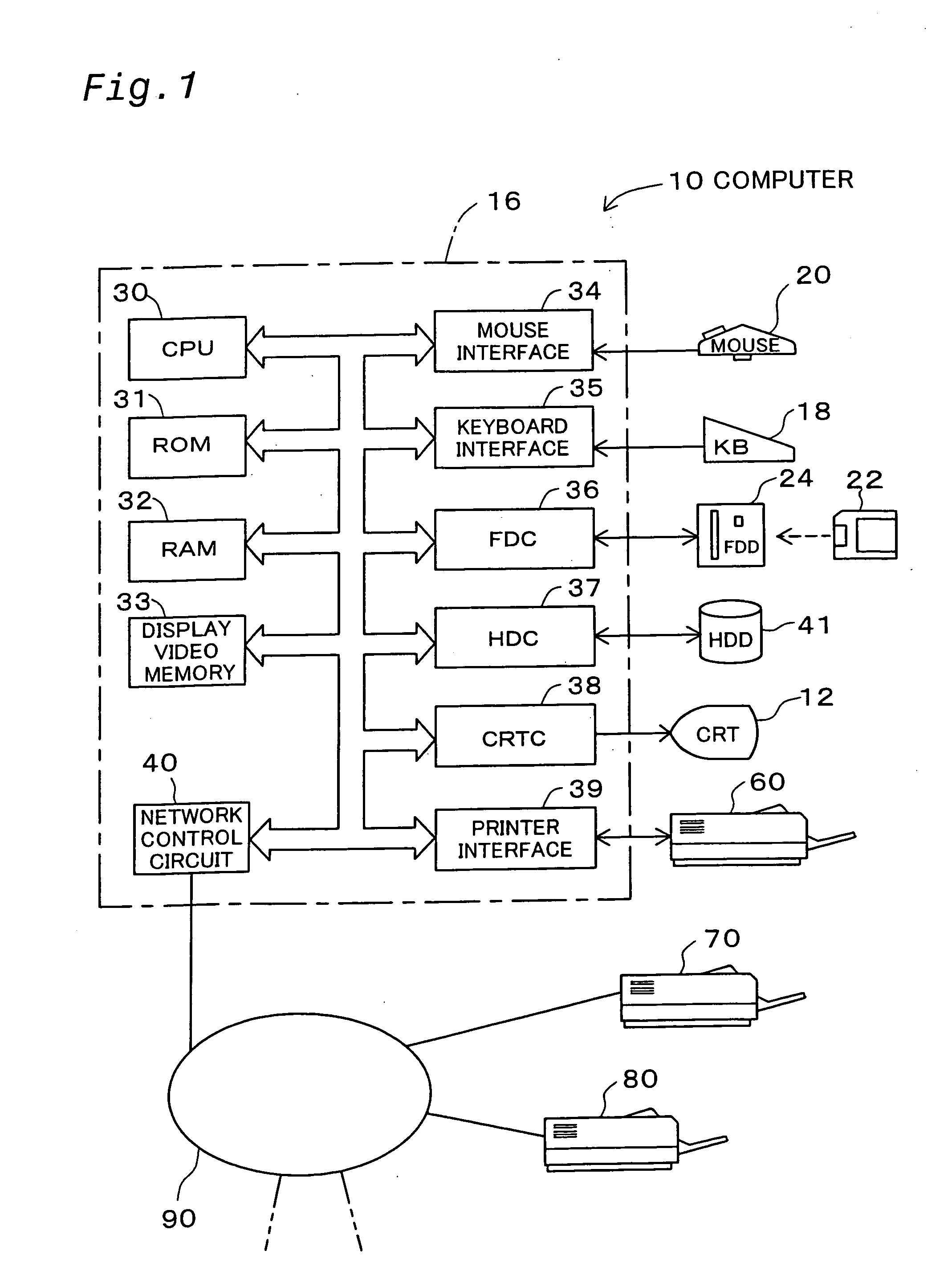

[0120]FIG. 1 is a block diagram schematically illustrating the hardware structure of a computer system in a first embodiment of the present invention. As illustrated, the computer system of the first embodiment includes a computer 10, which is connected with a plurality of printers 70, 80, . . . having substantial computer functions via a computer network 90 constructed as a Local Area Network (LAN). The computer network 90 is, however, not restricted to the LAN but may be any of diverse networks like the Inter...

second embodiment

B. Second Embodiment

B1. User Interface

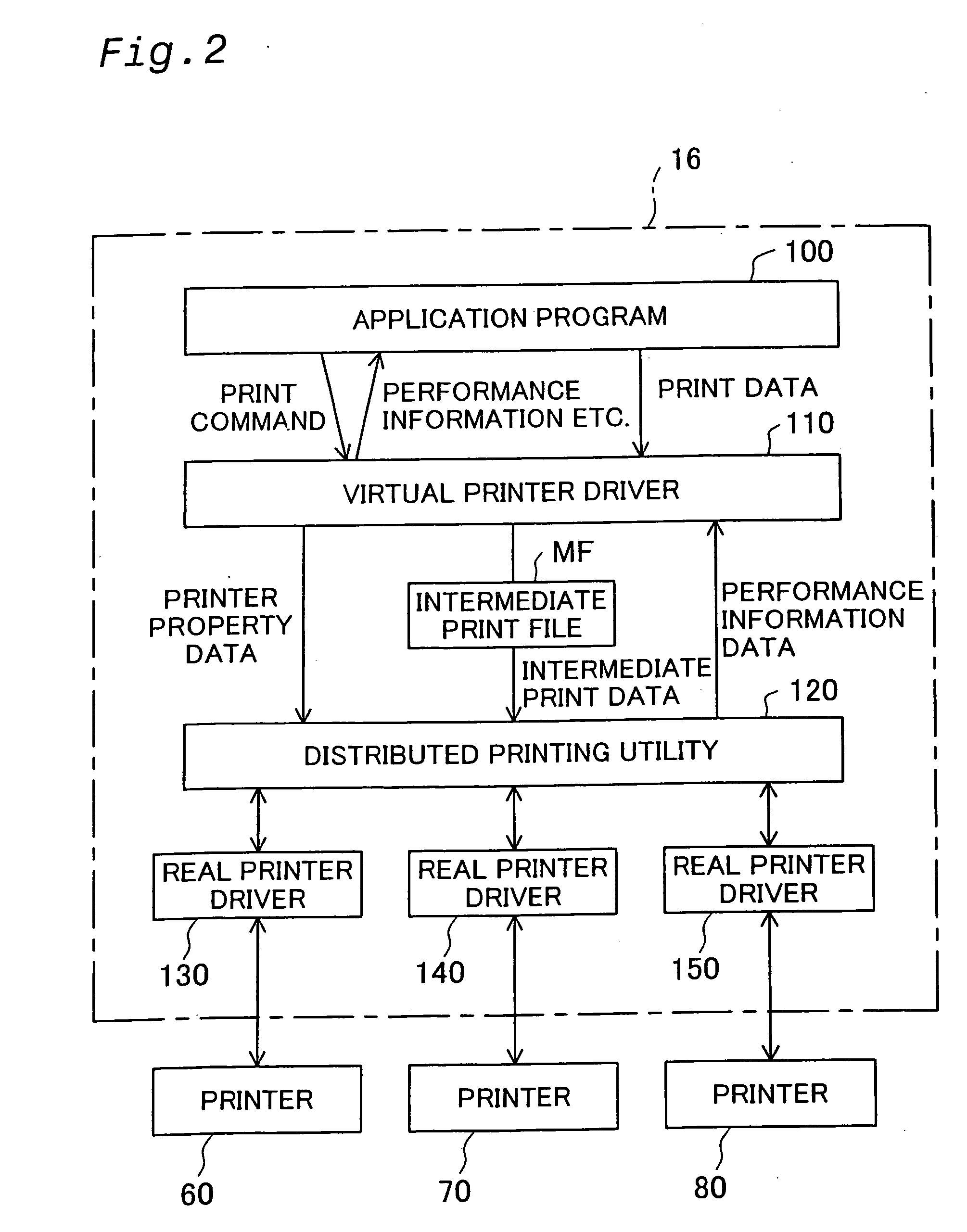

[0215] The following describes a second embodiment of the present invention. The details of ‘A1. General Hardware Structure’, ‘A2. Distributed Printing Process’, and ‘A3. Virtual Printer Driver’ discussed in the first embodiment are adopted in the second embodiment of the present invention. The same parts as those of the first embodiment are expressed by the same numerals. The differences between the first embodiment and the second embodiment are part of the details of the user interface and part of the computer programs. The details of the user interface are discussed first.

[0216] Like the first embodiment, in the structure of the second embodiment, a dialog box ‘Distributed Printing Properties’ is provided as the user interface. FIG. 21 illustrates a dialog box WN12‘Distributed Printing Properties’. Like the first embodiment, two cards CD11‘Distribution Settings’ and CD12‘Printer’ are provided in the dialog box WN12‘Distributed Printing Pro...

third embodiment

C. Third Embodiment

C1. Distributed Printing Process

[0279] The following describes a third embodiment of the present invention. The details of ‘A1. General Hardware Structure’, ‘A2. Distributed Printing Process’, ‘A3. Virtual Printer Driver’, and ‘A4. User Interface’ discussed in the first embodiment are adopted in the third embodiment of the present invention. The same parts as those of the first embodiment are expressed by the same numerals. The third embodiment has unique characteristics in the ‘Distributed Printing Process’.

[0280]FIG. 37 is a block diagram showing the functions of a distributed printing utility 120C in the third embodiment. As illustrated, the distributed printing utility 120C includes an intermediate print data input module 121, a property data input module 122, an allocation specification module 123, an output data control module 124, a printer setting module 125, an output command output module 126, a performance information input module 127, a final print ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com