Knife sharpener

a sharpener and blade technology, applied in the field of knife sharpeners, can solve the problems of affecting the precise angle at which the knife meets the sharpening rod, the use of a fixed stop member on the front of the housing plate, and the use of a housing plate with all components attached to the front of their uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

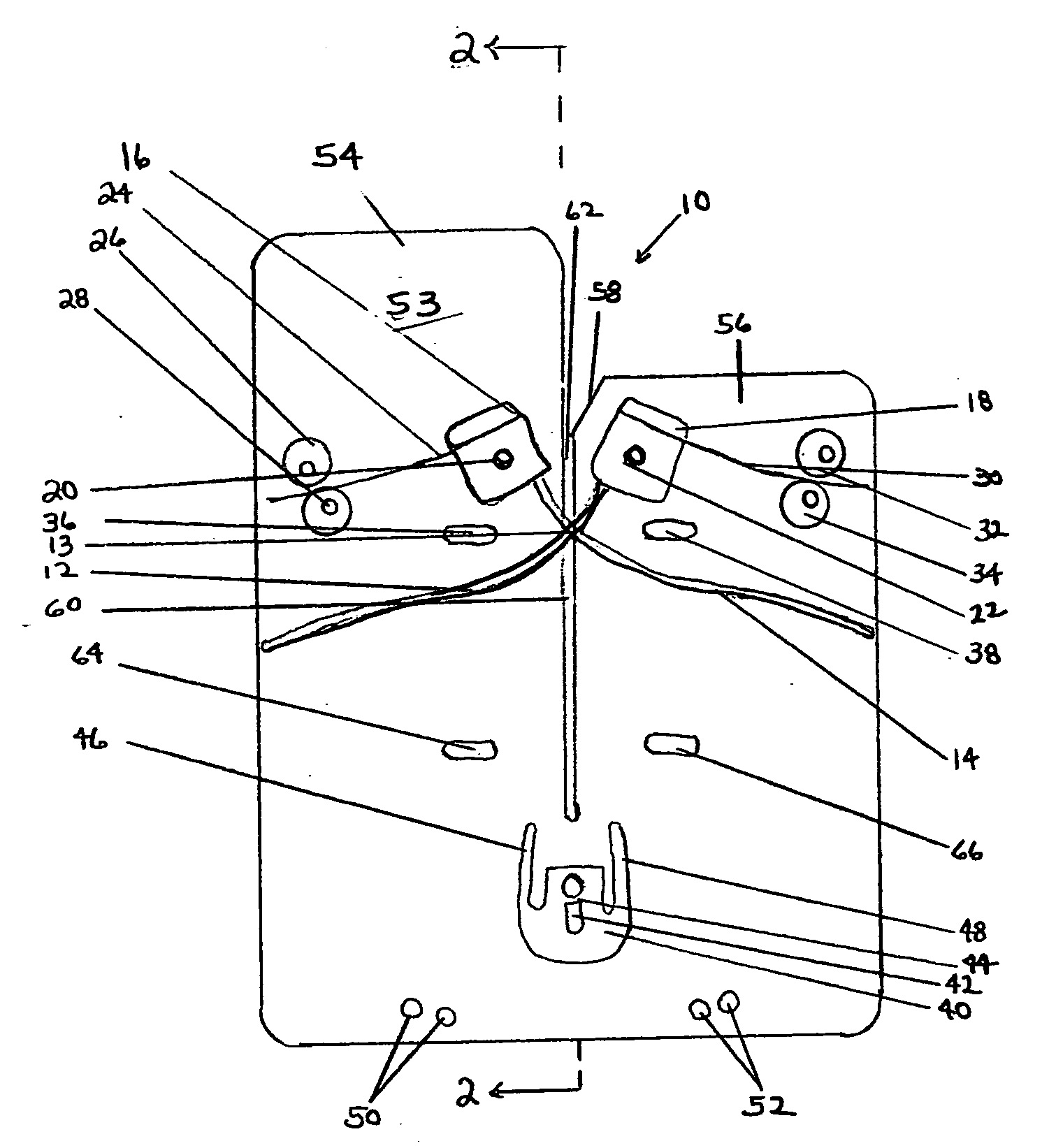

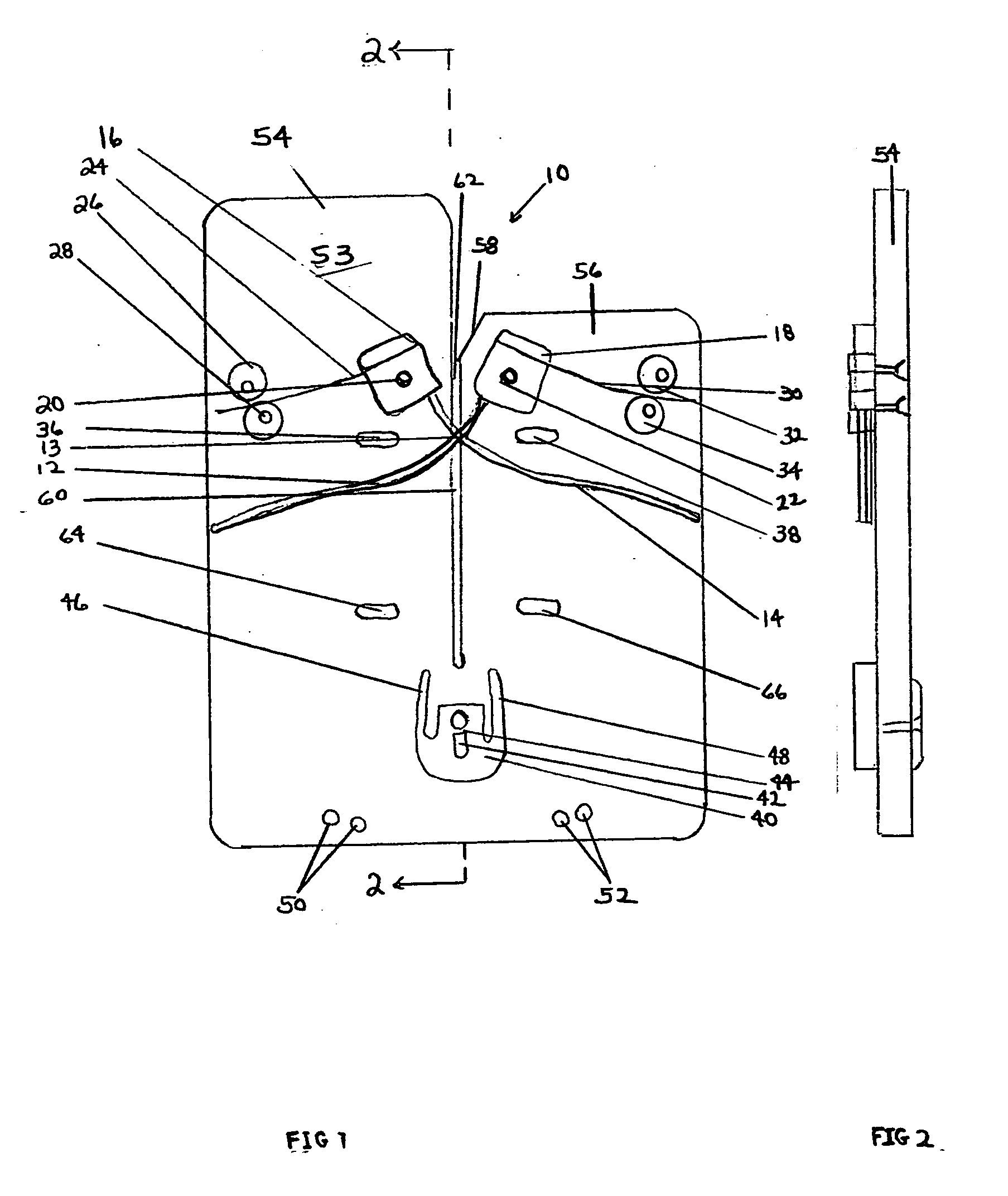

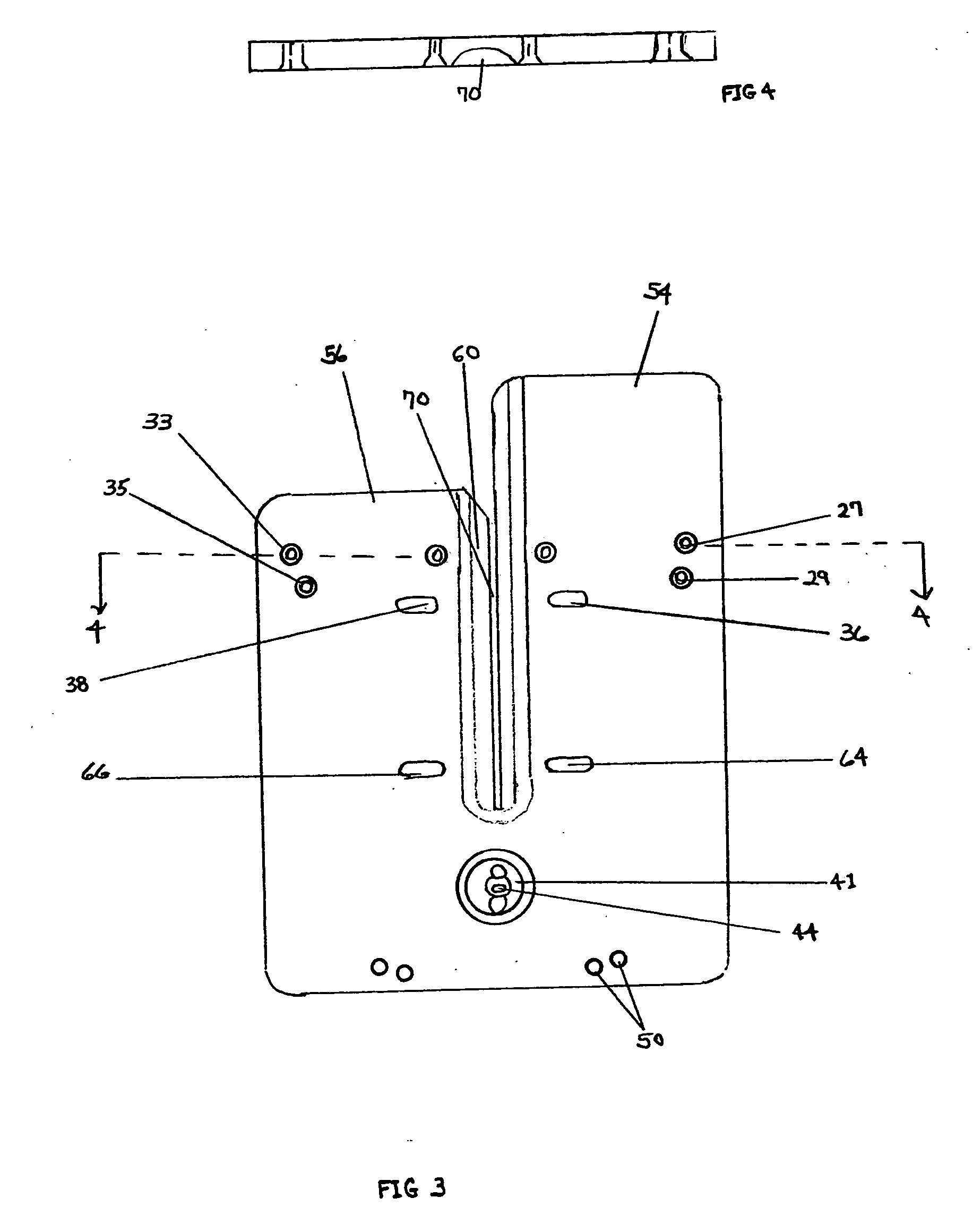

[0023] With reference to the drawings and primarily FIG. 1, the knife sharpener 10 of the present invention is comprised in the main of a housing plate 53 with two main sections 54 and 56 that are separated by a knife slot 60. The housing plate supports a pair of pivotally movable sharpening rods 12, 14 that are resiliently biased toward an initial position by spring arms 24, 30, the sharpening rods crossing one another at a movable V-shaped intersection point 13, the location of which moves along the slot 60, as a knife is pressed down the slot 60.

[0024] The housing plate 53 is preferably made of a solid, ½ inch thick UHMW and / or high-density polyethylene, durable, one-piece construction material. It has been designed so that the knife blade 77 (FIG. 8) will avoid cutting into the housing plate 53 during normal use. The blind high wall 55 (FIG. 8) on the right side of the housing plate 53 helps guide the blade 77 down into the sharpening slot 60.

[0025] Four adjustable upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com