Improved capsule filling machine

a filling machine and capsule technology, applied in special packaging, packaging, packaging types, etc., can solve the problems of requiring a certain degree of attention from the operator, difficult operation, and laborious manoeuvre, and achieve the effect of improving the filling of capsules, precise vertical positioning of capsules, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

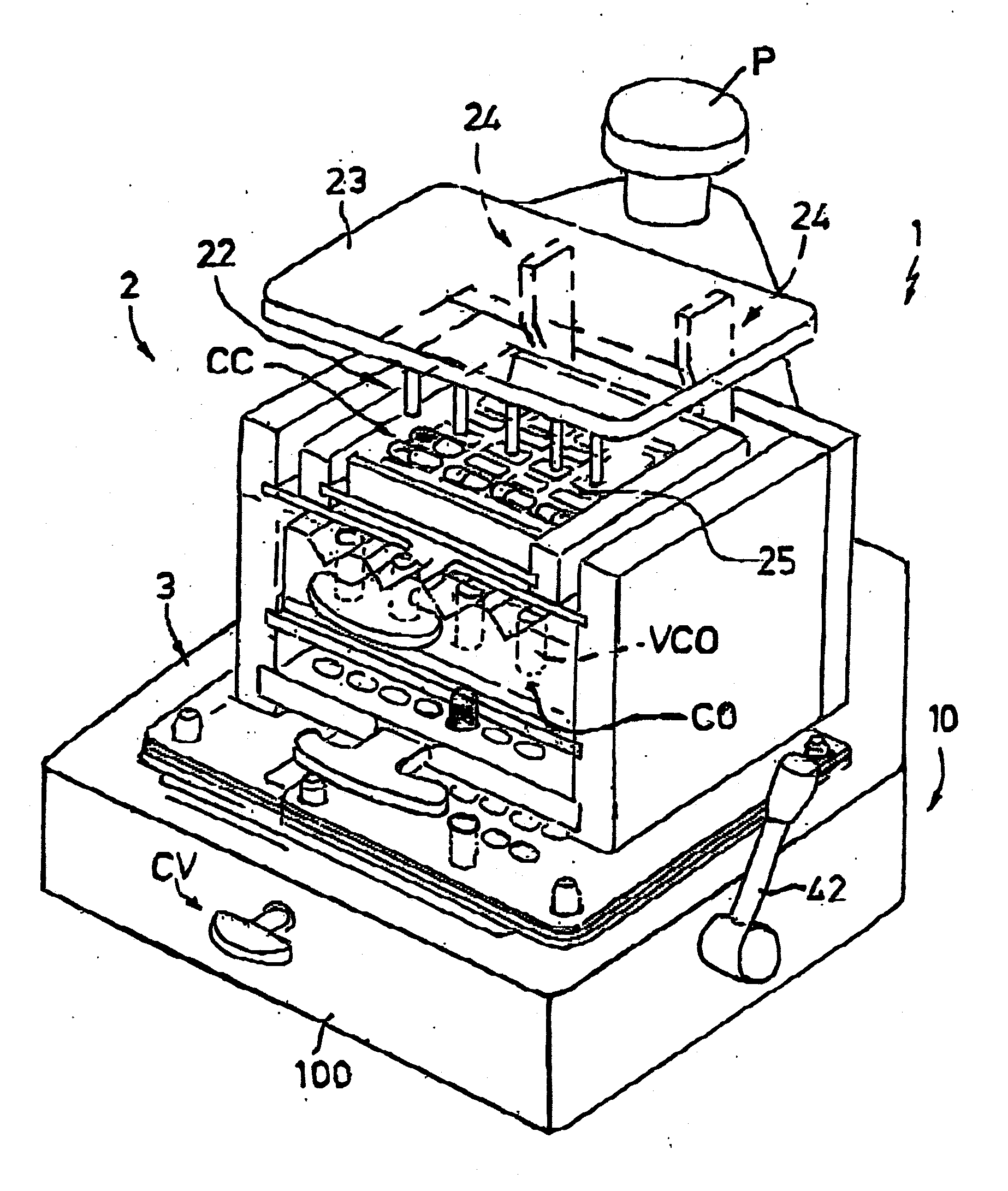

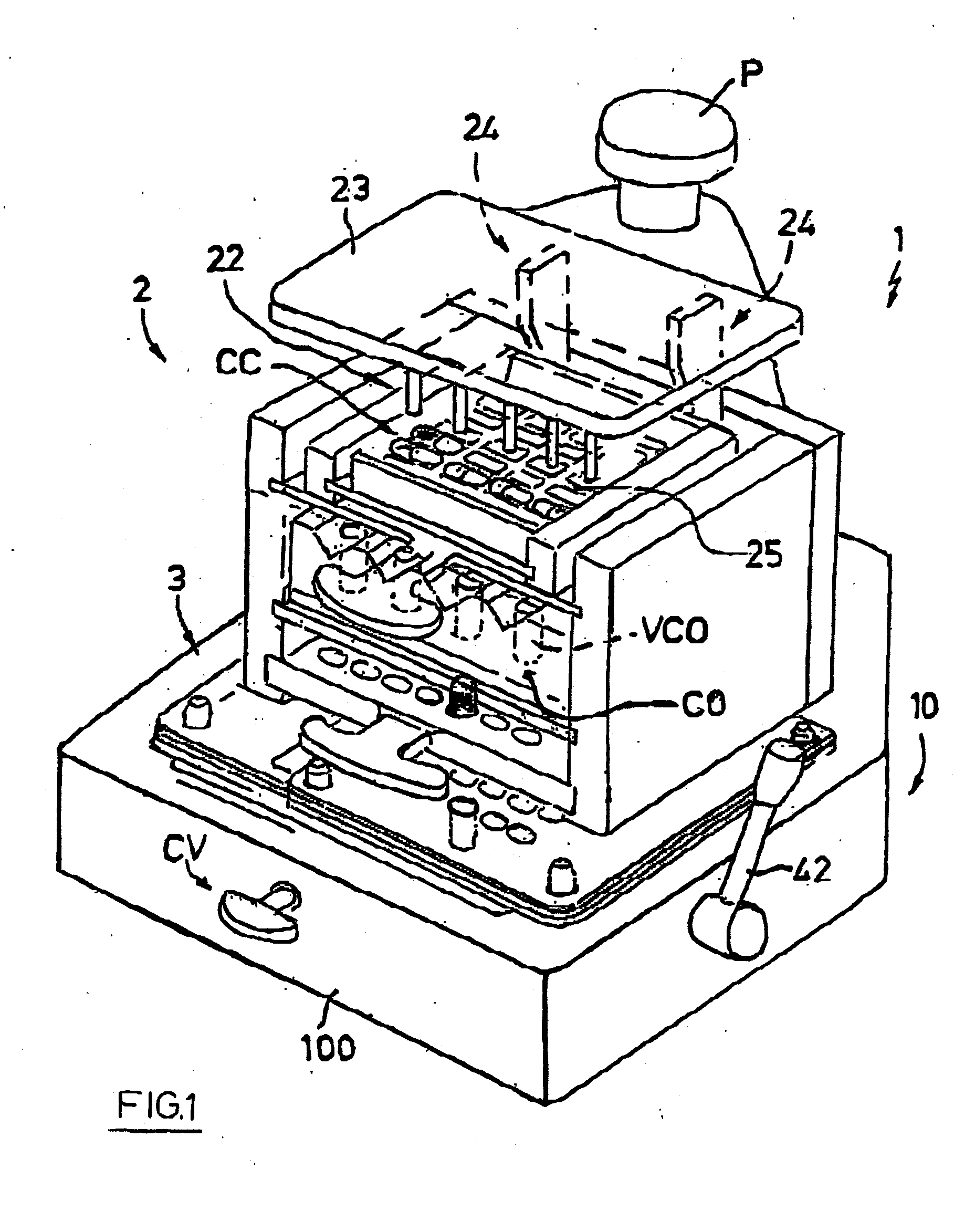

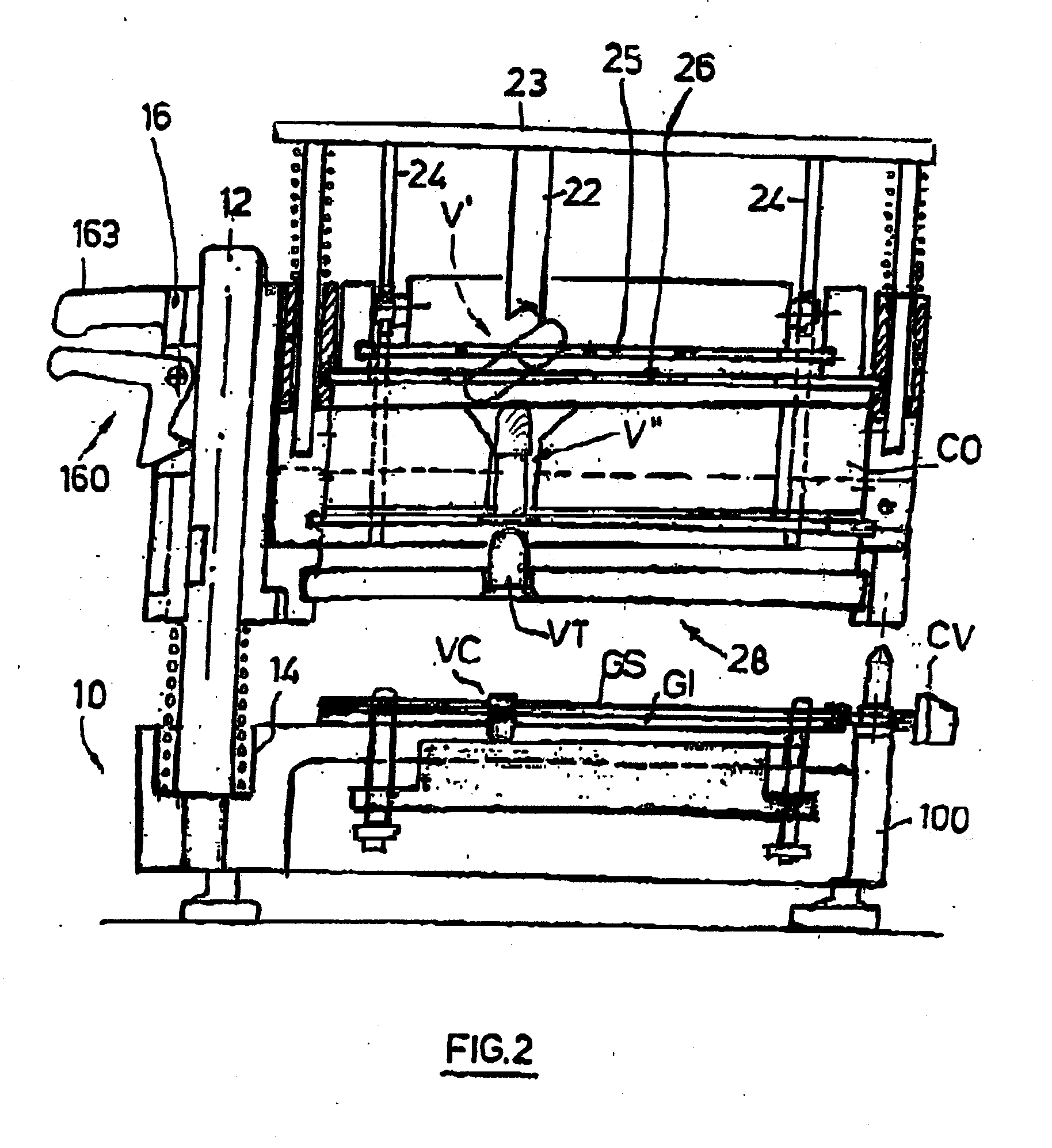

[0025] Reduced to its essential structure and with reference to the figures in the enclosed drawings, a capsule filling machine according to the present invention comprises: [0026] a bearing structure (1); [0027] a unit (2) for filling and orienting the capsules to be treated, said unit (2) being associated with the aforesaid structure (1); [0028] a unit (3) for opening the capsules and closing them when they have been filled, also said unit (3) being associated with the bearing structure (1) and positioned below the unit (2) for filling and orienting the capsules.

[0029] Advantageously, in conformity with the present invention, the unit (2) for filling and orienting the capsules is anchored to the structure (1), with the possibility of rotation around a vertical axis of the structure (1) and of movement along the same vertical axis.

[0030] In this way, the unit (2) may assume a position of vertical overlapping with the other unit (3) of the machine, close to it or at a distance, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degrees of freedom | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com