Firearms projectile having jacket runner

a projectile and jacket technology, applied in the field of small munitions projectiles, can solve the problems of affecting the accuracy of fired bullets, affecting the accuracy of downrange, and affecting the velocity and accuracy of fired bullets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

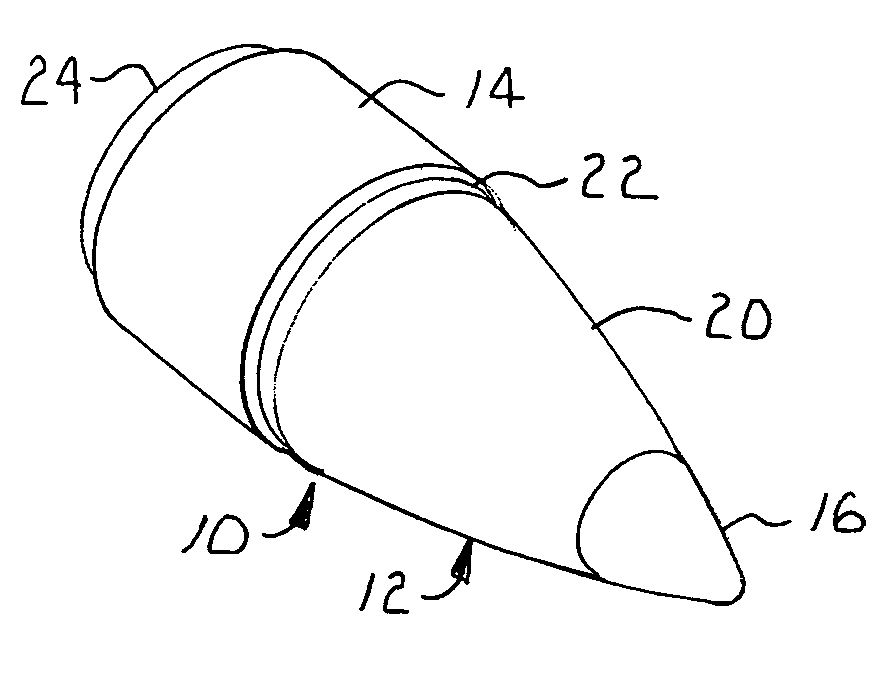

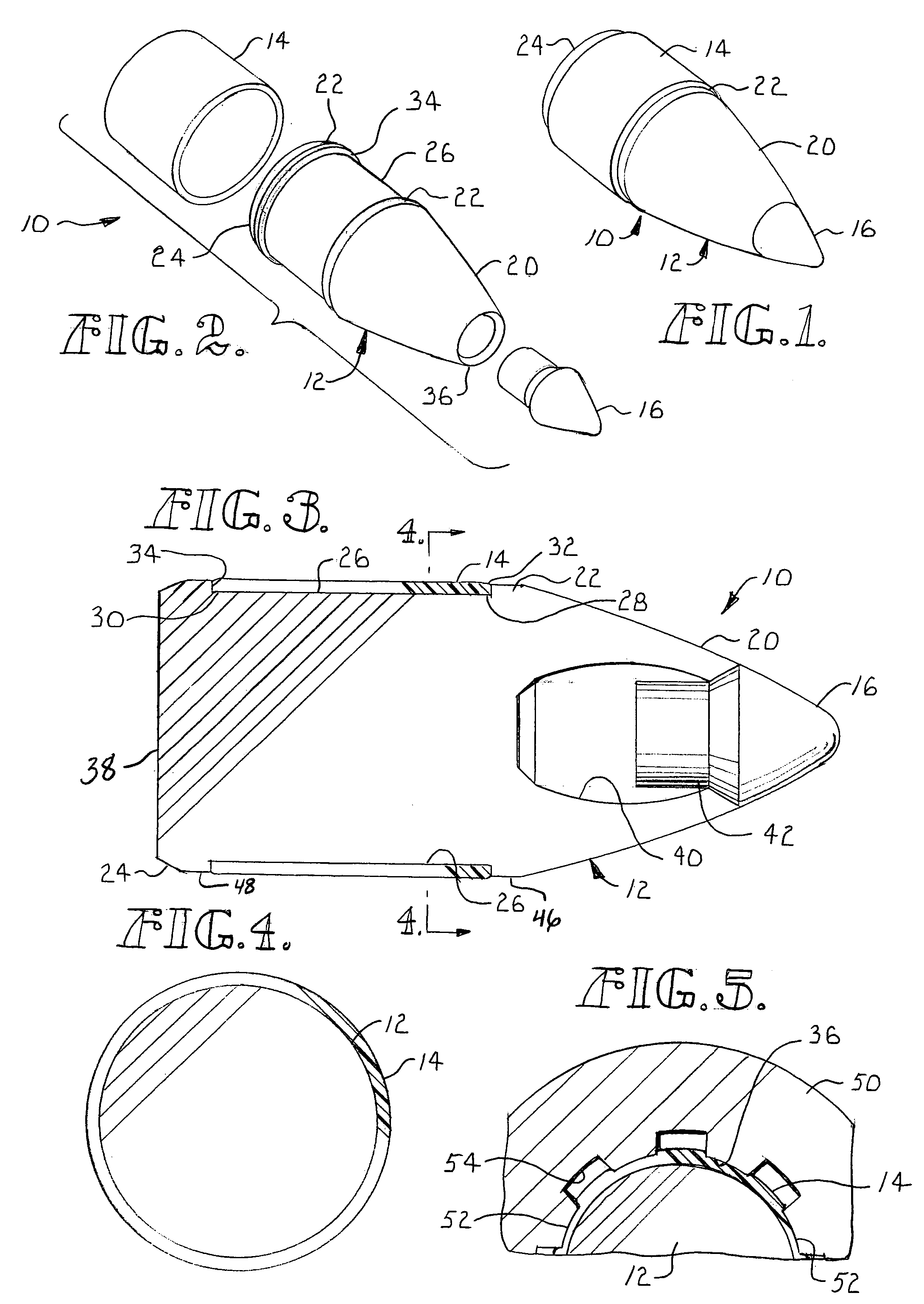

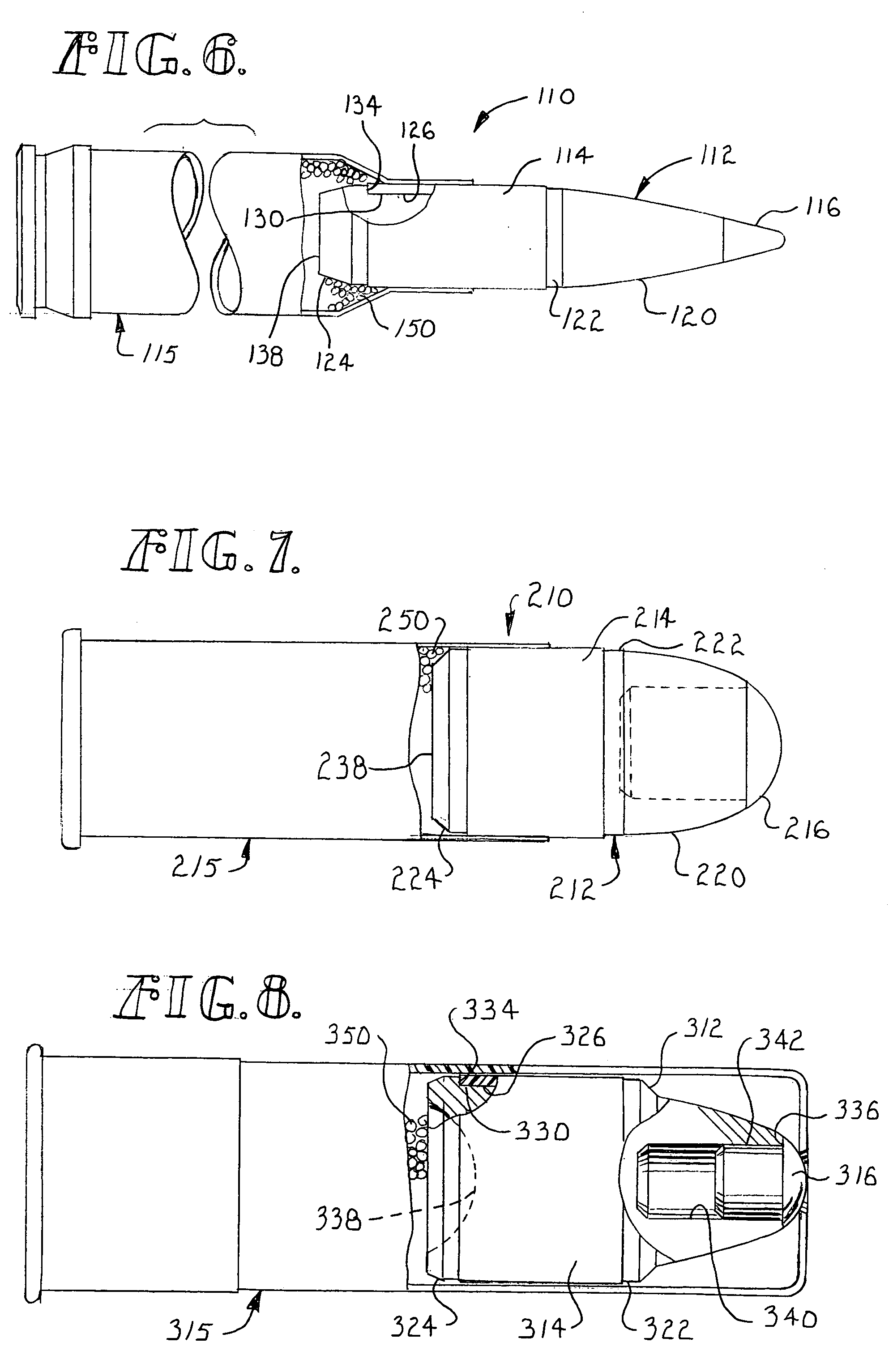

[0020] Turning now to the FIGS., and particularly to FIGS. 1-3, a projectile 10 for small munitions is depicted, and includes a bullet 12 and an integral jacket runner 14. Optionally, the projectile can also include a tip 16 positioned on one end thereof.

[0021] Bullet 12 includes a tapered front section 20, a cylindrical middle section or shank 22, and a tapered end section 24. Section 20 includes opposed top 46 and bottom 48 ends, and intermediate these opposed ends is a recessed receiving portion 26 for receiving and retaining jacket runner 14 thereon. Both middle section 22 and recessed receiving portion 26 are preferably circular in cross-section. Recessed receiving portion 26 has opposed leading and trailing edges 28 and 30; respectively. Leading edge 28 is connected to top end 46 by first shoulder 32, and trailing edge 30 is connected to bottom end 48 by second shoulder 34. Shoulders 32, 34 can form any suitable size and angle with respect to the outer diameter and longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com